Supported optical catalyst preparation method

A photocatalyst and load-type technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of poor benzene removal effect, avoid secondary pollution, realize in-situ regeneration, The effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0013] Specific implementation mode 1: The supported photocatalyst in this implementation mode is loaded with 1 to 5 layers of TiO on the surface 2 Granular activated carbon fibers.

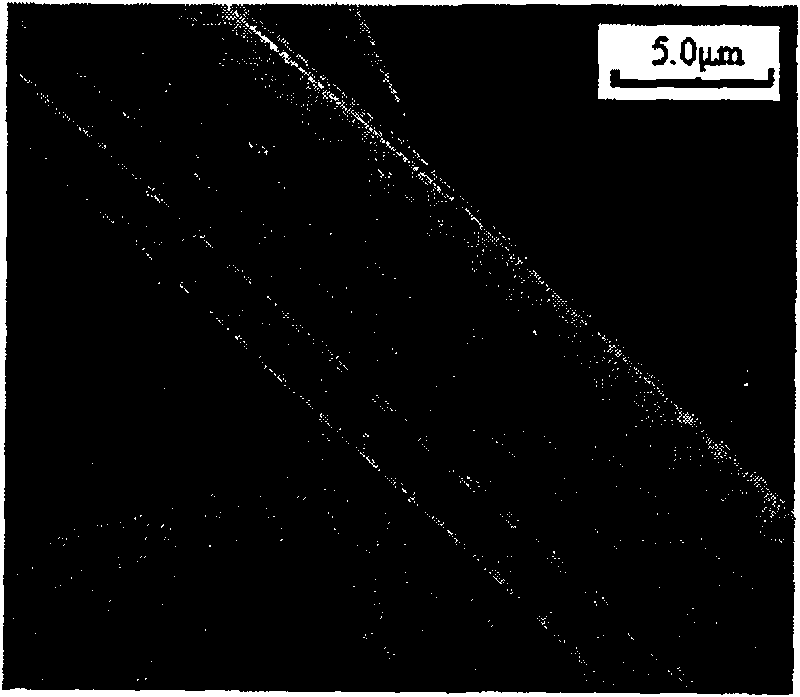

[0014] SEM image of activated carbon fiber figure 1 shown.

[0015] The specific surface area of the activated carbon fiber used in this embodiment is 800-1500m 2 / g, the total pore volume is 0.35~0.65m 2 / g, the aperture is

specific Embodiment approach 2

[0016] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the surface-loaded TiO 2 The particle size of the particles is 10-13 nm. Others are the same as the first embodiment.

[0017] After testing the TiO in this embodiment 2 The particle diameter is 10-13nm, and the critical size is 13nm, so it has high activity.

specific Embodiment approach 3

[0018] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the supported photocatalyst is that the surface is loaded with 2 layers of TiO 2 Granular activated carbon fibers. Others are the same as the first embodiment.

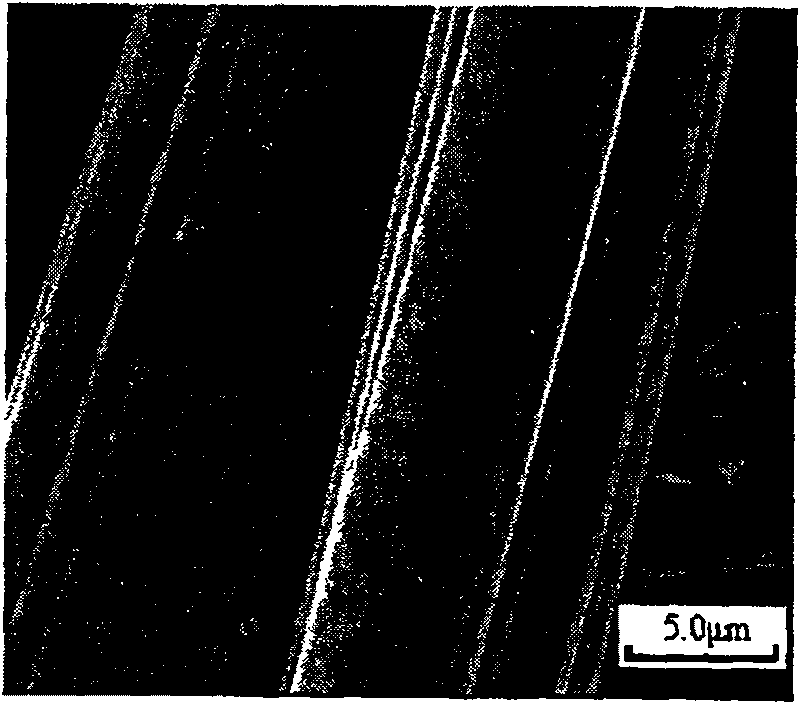

[0019] image 3 It is a scanning electron micrograph of the supported photocatalyst in this embodiment, and the surface of the supported photocatalyst is dense and smooth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com