Method for manufacturing 460Mpa high-toughness medium plate for bridge

A production method and high-strength-toughness technology are used in the production of 460Mpa high-strength and toughness medium-thick steel plates for bridges, and in the production field of high-strength-toughness medium-thick steel plates for bridges with a yield strength of 460Mpa, which can solve the problems of high production costs, poor toughness and welding adaptability, Low carbon steel smelting is not economical and other problems, to achieve the effect of good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention can be implemented in steel and steel enterprises with wide and thick plates. The following is an example of using the present invention to produce medium and thick steel plates for bridges with a yield strength of 460Mpa.

[0017] The process route is: hot metal desulfurization and slag removal → 100t converter smelting → ladle deoxidation alloying → ladle furnace refining → RH vacuum treatment → feeding Si-Ca line → slab casting machine pouring → slab heating → 4300mm rolling mill controlled rolling → controlled cooling → Finished product inspection.

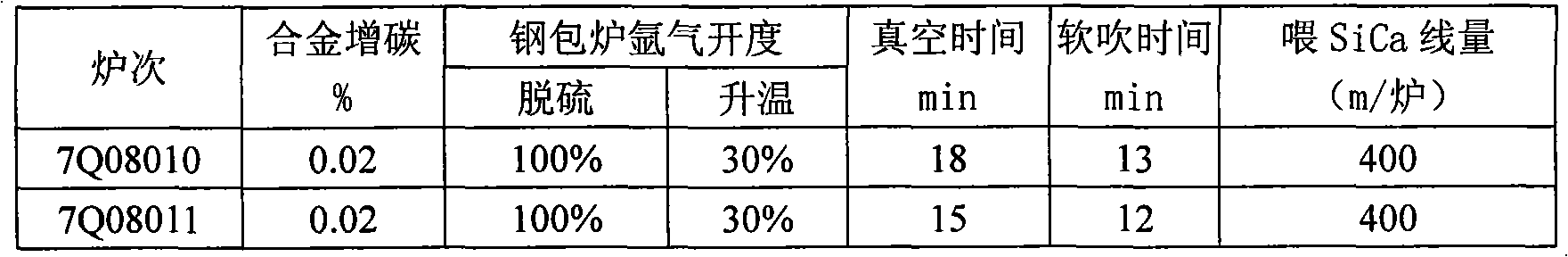

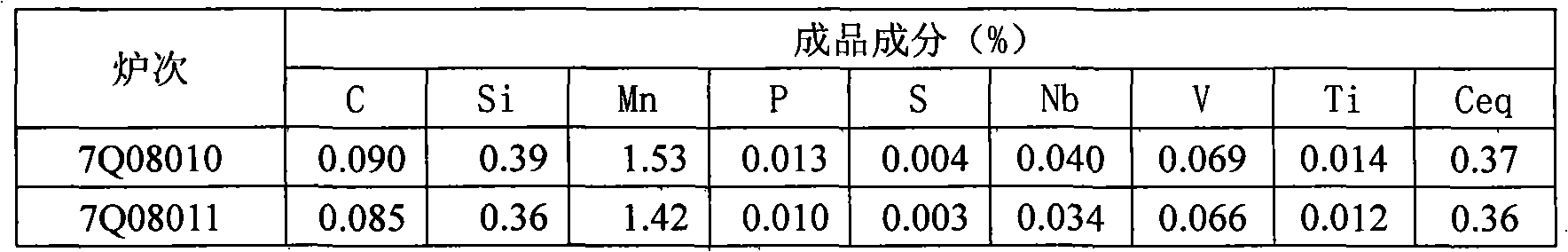

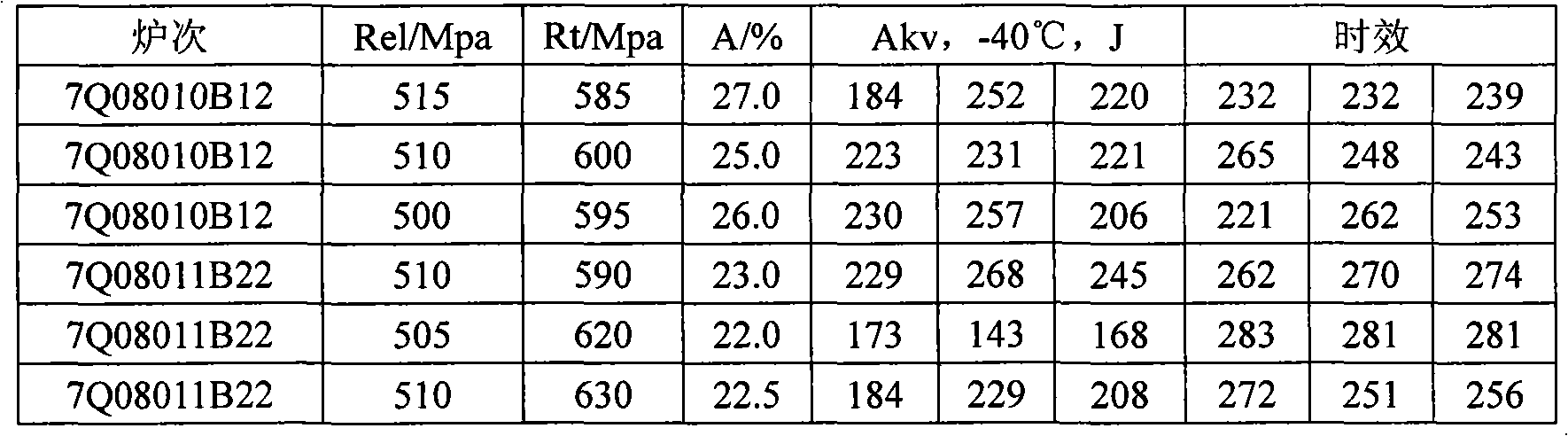

[0018] The main process parameters of the converter are shown in the table below.

[0019]

Stoves

Converter end temperature

(℃)

converter end point

C, (%)

Ferrosilicon manganese addition amount

(kg / t)

The amount of micro-carbon ferromanganese added

(kg / t)

7Q08010

1706

0.028

5.6

13.6

7Q080...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com