Novel plate type solar heat collection method and its heat collectors

A solar heat collector, a technology for solar heat collection, applied in the field of solar energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

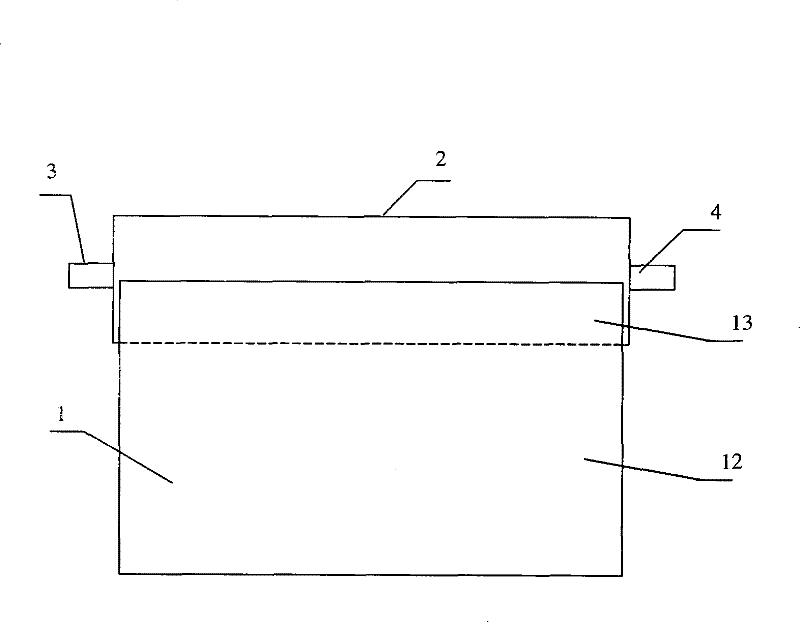

[0034] Such as figure 1 Shown is the structural schematic diagram of the solar heat collector of the present invention.

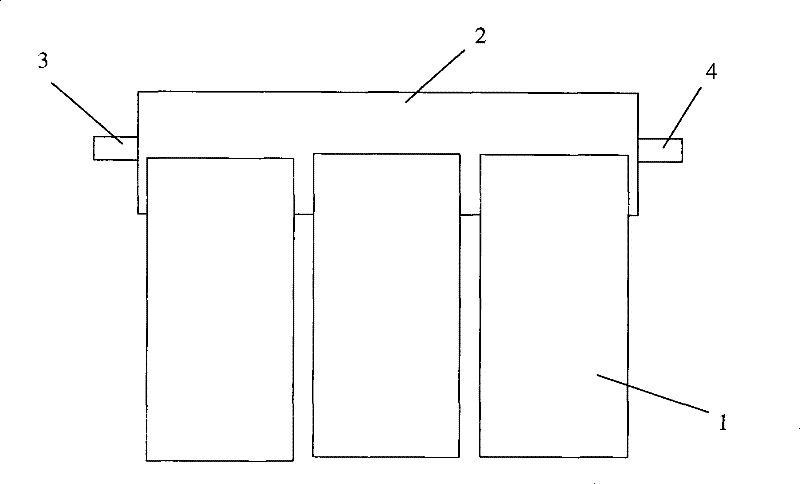

[0035] In this embodiment, the solar heat collector includes a heat absorbing plate 1 of a flat structure, a heat exchanger 2 and its inlet and outlet—water pipes 3 and water pipes 4, wherein the heat absorbing section 12 of the heat absorbing plate 1 is exposed to the sun to absorb sunlight. , the heat release section 13 is arranged in the heat exchanger 2 , the heat release section 13 condenses and releases heat in the heat exchanger 2 , and heats the stored water in the heat exchanger 2 .

[0036] The sun-facing side of the heat-absorbing section 12 is a light-absorbing surface, on which a heat-absorbing coating 8 that can efficiently absorb solar energy is provided (see Figure 5 , Image 6 ), in order to improve the heat absorption efficien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com