Lateral diffusion metal-oxide-semiconductor element with low opening resistor and manufacturing method thereof

A technology of turn-on resistance and manufacturing method, which is applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of decrease of saturation current and increase of turn-on resistance, and achieve reduction of turn-on resistance, increase of saturation current, and easy alignment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

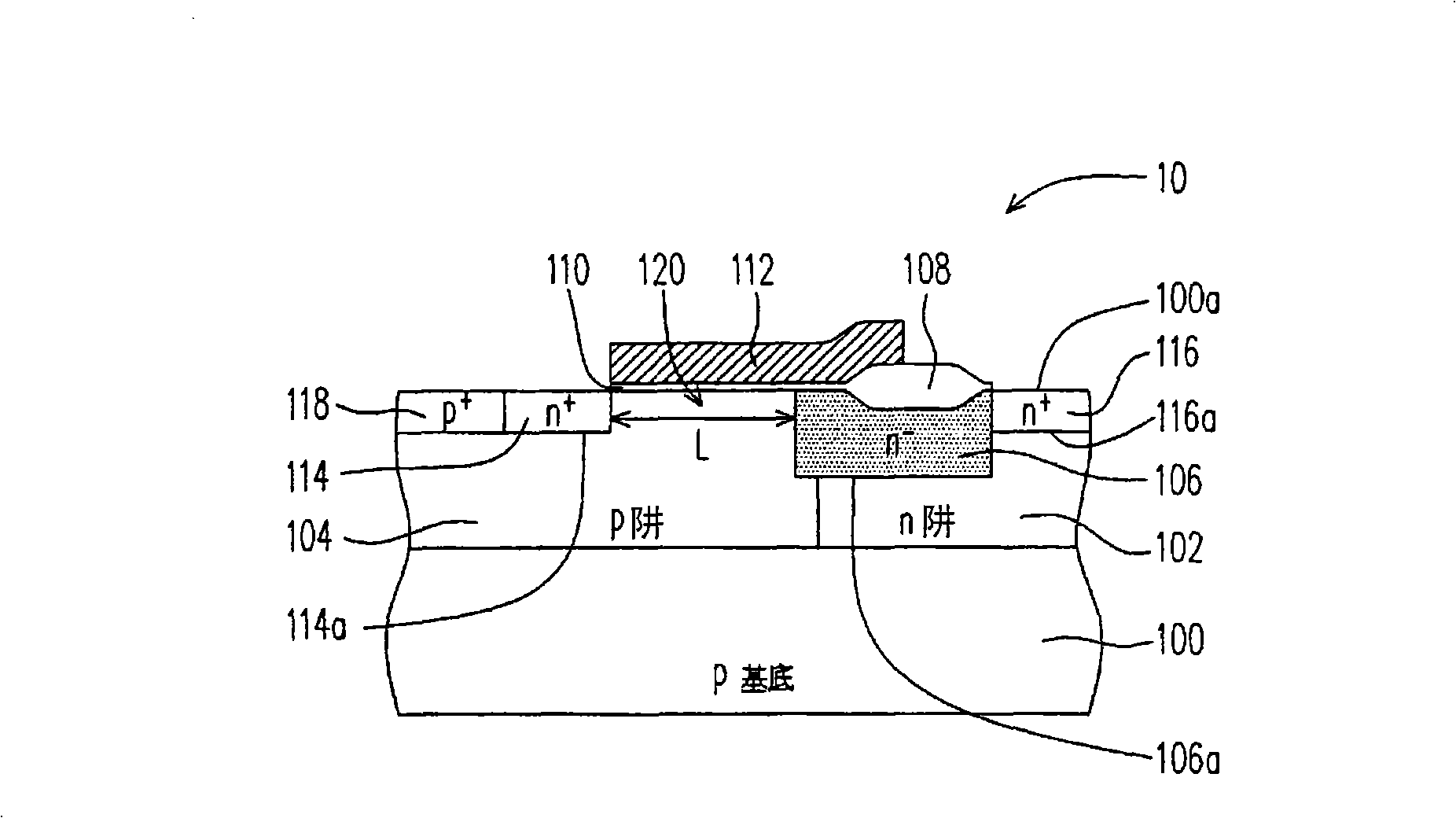

[0023] figure 1 It is a laterally diffused metal oxide semiconductor device according to an embodiment of the present invention.

[0024] Please refer to figure 1 The laterally diffused metal oxide semiconductor element 10 includes an N-type well region 102, a P-type well region 104, an N-type doped region 106, a field oxide layer 108, and an N-type doped region 116 as an N-type drain region and an N-type The doped region 114 serves as an N-type source region, a gate dielectric layer 110 , a gate conductive layer 112 and a P-type base contact region (bulk contact region) 118 .

[0025] The N-type well region 102 is adjacent to the P-type well region 104 and both are located in the substrate 100 . The method for forming the N-type well region 102 and the P-type well region 104 can be achieved by forming a photoresist pattern respectively and using an ion implantation preparation process and a drive-in step.

[0026] The source region 114 is located in the P-type well region ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com