Fibre reinforced multi-layer fluorine-contained ionic exchange film

An ion-exchange membrane, fiber-reinforced technology, applied in the field of functional polymer composite materials, can solve the problems of continuous production, time-consuming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

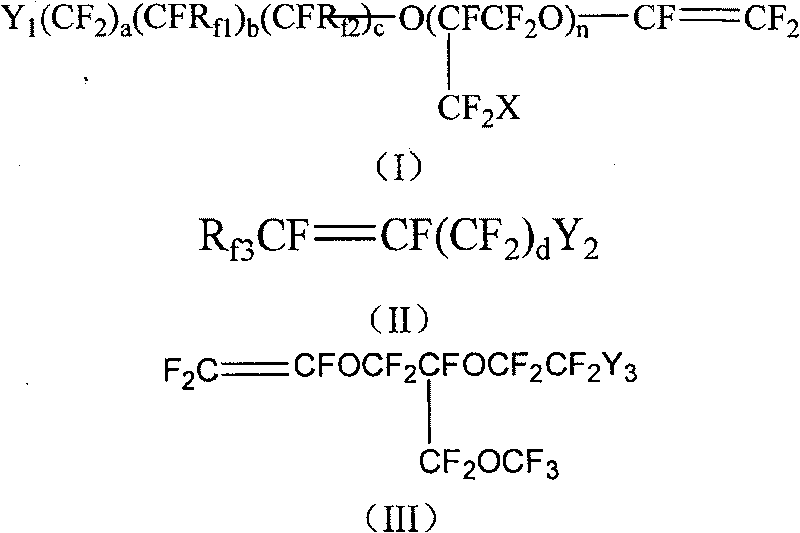

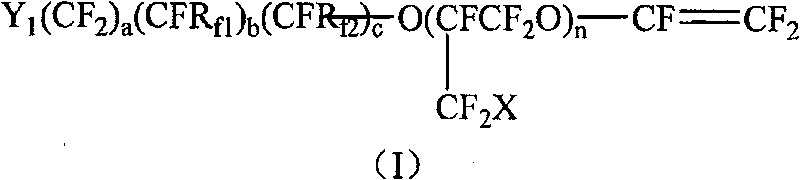

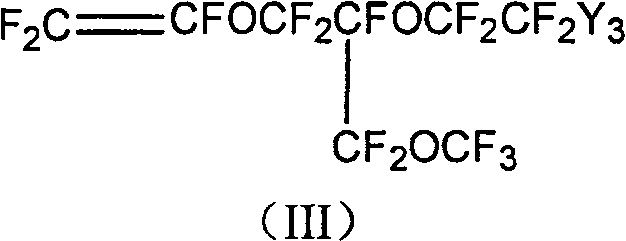

Method used

Image

Examples

Embodiment 1

[0048] Placing PTFE fibers in SiCl 4 After being in the atmosphere for 1 hour, the temperature was raised to 110° C. and maintained for 1 hour, and then cooled to 60° C., and sprayed with water to obtain silica-modified polytetrafluoroethylene fibers.

Embodiment 2

[0050] Put alkali-free glass fiber in Ti(OEt) 4 Add concentrated ammonia water to hydrolyze and stand still in the water mixing system under stirring to obtain the alkali-free glass fiber modified by titanium dioxide.

Embodiment 3

[0052] Triethyl phosphate and tetraethyl orthosilicate (1:100 mass ratio) were mixed and added to water and concentrated ammonia water to static gel for 12 hours, and then the gel was used to obtain phosphoric acid-modified silica fibers by electrospinning or spinning technology

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com