High-energy potassium salt, and preparation and use method thereof

A potassium salt and organic technology, applied in the field of novel energy-containing flame suppressant-high-energy organic potassium salt and its preparation, can solve problems such as inability to be widely used, achieve easy industrial production, suppress secondary combustion, and reduce infrared radiation intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0021] Specifically, the preparation method of energy-containing organic potassium salt of the present invention is:

[0022] (1) First suspend DNMDZ in distilled water, slowly add KOH under stirring condition;

[0023] (2) add methanol after reacting for a certain period of time, and properly heat for a certain period of time;

[0024] (3) Cool the reaction solution, a large number of light yellow crystals precipitate out, filter, wash and vacuum dry to obtain the product.

[0025] The amount of reactant is:

[0026] DNMDZ to KOH molar ratio: 1:1.5-1:2.5;

[0027] The mass ratio of distilled water: DNMDZ is 4:16:1;

[0028] The reaction conditions are:

[0029] Reaction time: 10-30min;

[0030] Methanol: distilled water consumption ratio is 2: 1-4: 1, when methanol consumption is less than 2 times of distilled water consumption, yield is very low and impure or cannot obtain product;

[0031] Temperature: 40-60°C, not exceeding 60°C;

[0032] Cooling, washing and drying...

Embodiment 1

[0038] Embodiment 1: the synthesis of ligand

[0039] Dissolve 2.96g of 1,1-diamino-2,2-dinitroethylene (FOX-7) into 12mL of N-methylpyrrolidone, add 2.96g of ethylenediamine under stirring conditions, and heat to 110°C After stirring and reacting for 48 hours, cool to room temperature, add an appropriate amount of distilled water, a large number of light yellow fine crystals precipitate immediately, filter, wash with distilled water and vacuum dry to obtain the ligand-DNMDZ product. Yield 67% (2.33 g).

Embodiment 2

[0040] Embodiment 2: the synthesis of K (DNMDZ)

[0041] At room temperature, 0.01mol (1.74g) DNMDZ was dispersed in 10mL of distilled water, and 0.02mol (1.12g) KOH was slowly added under stirring conditions. After 30min of reaction, 30mL of methanol was added, heated to 50°C, and put into the freezer of the refrigerator after 10min. That is, a large amount of pale yellow crystals precipitated, filtered, washed with methanol and dried in vacuo to obtain the target product K(DNMDZ), with a yield of 71% (1.24g)

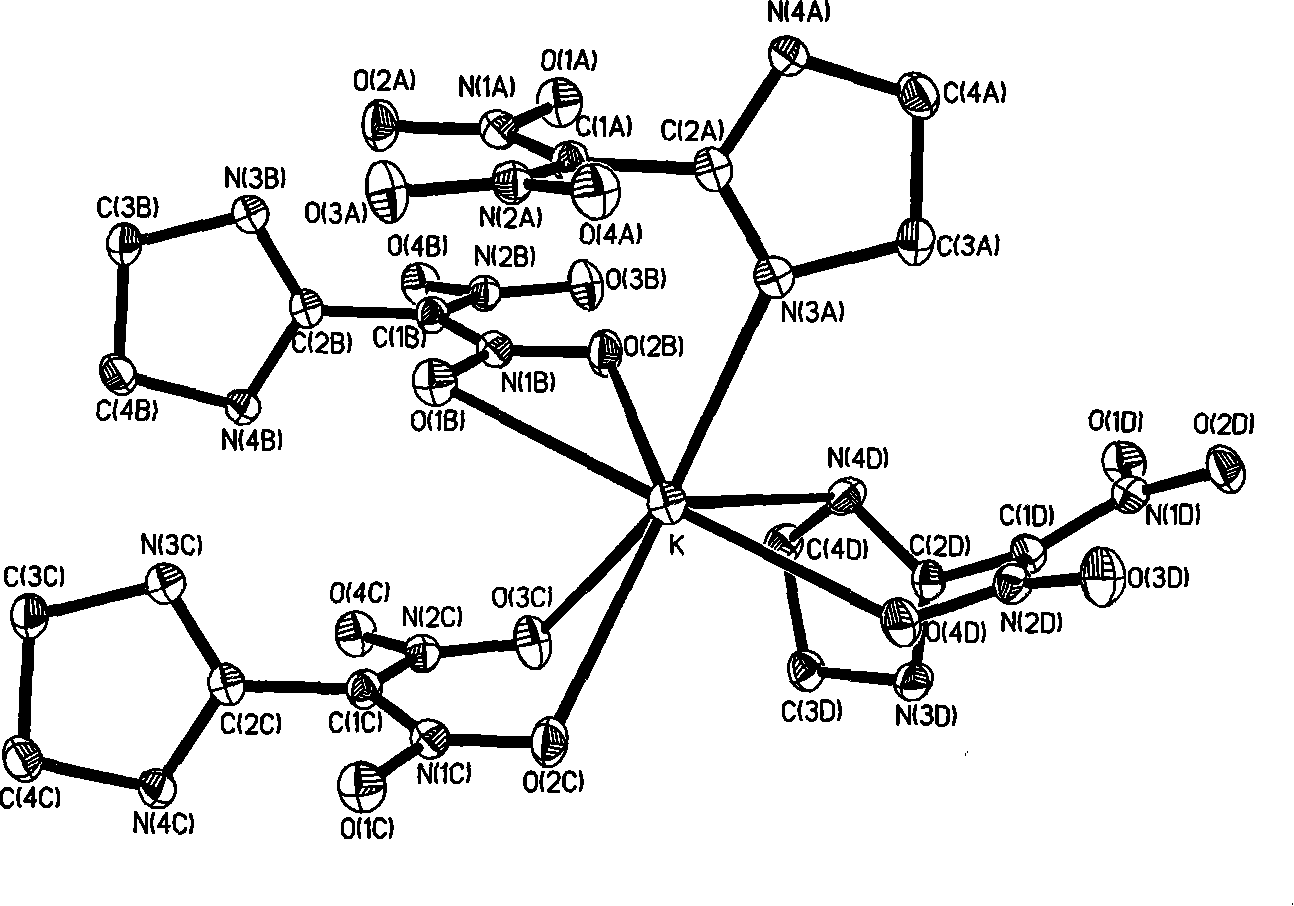

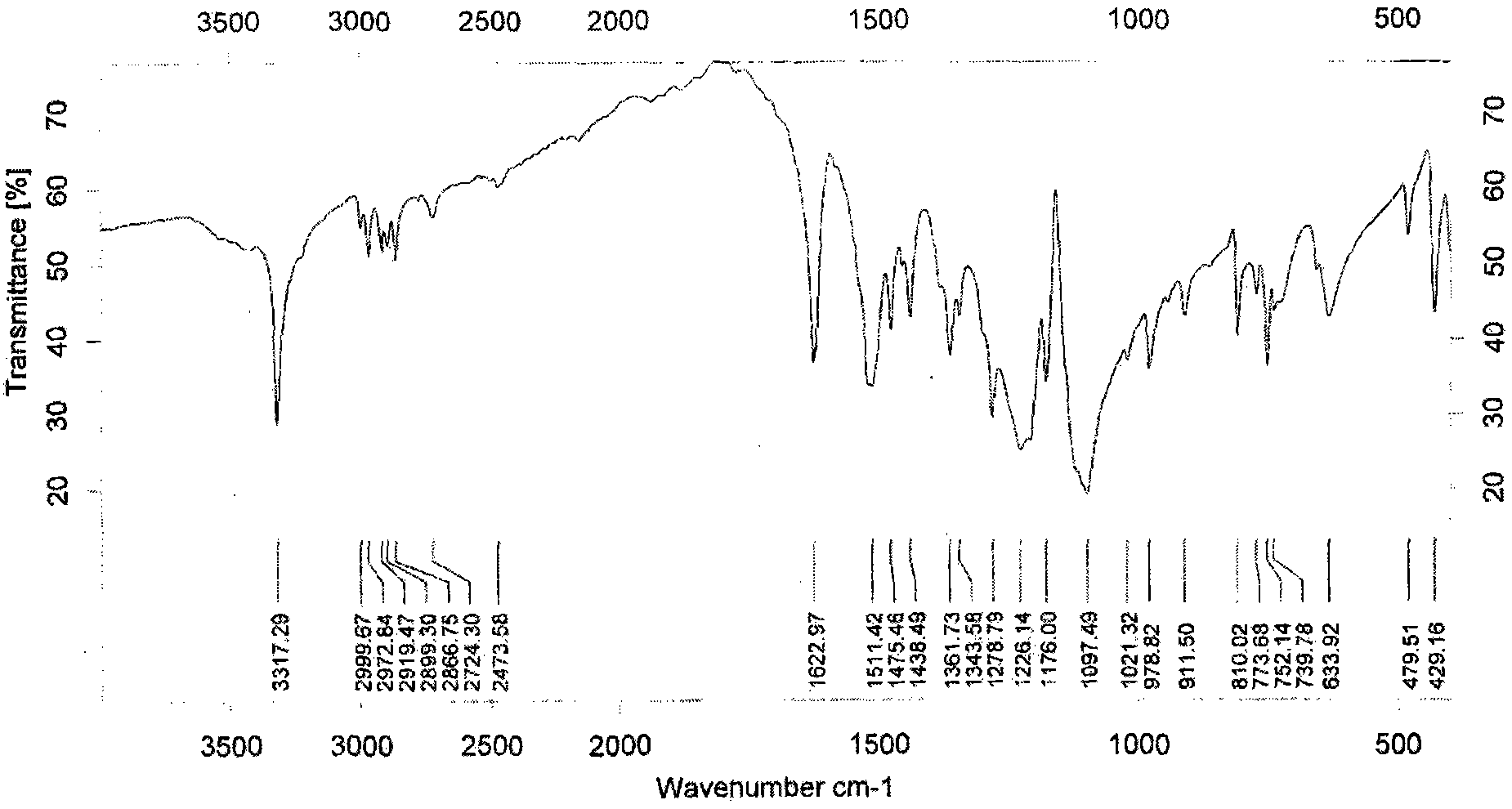

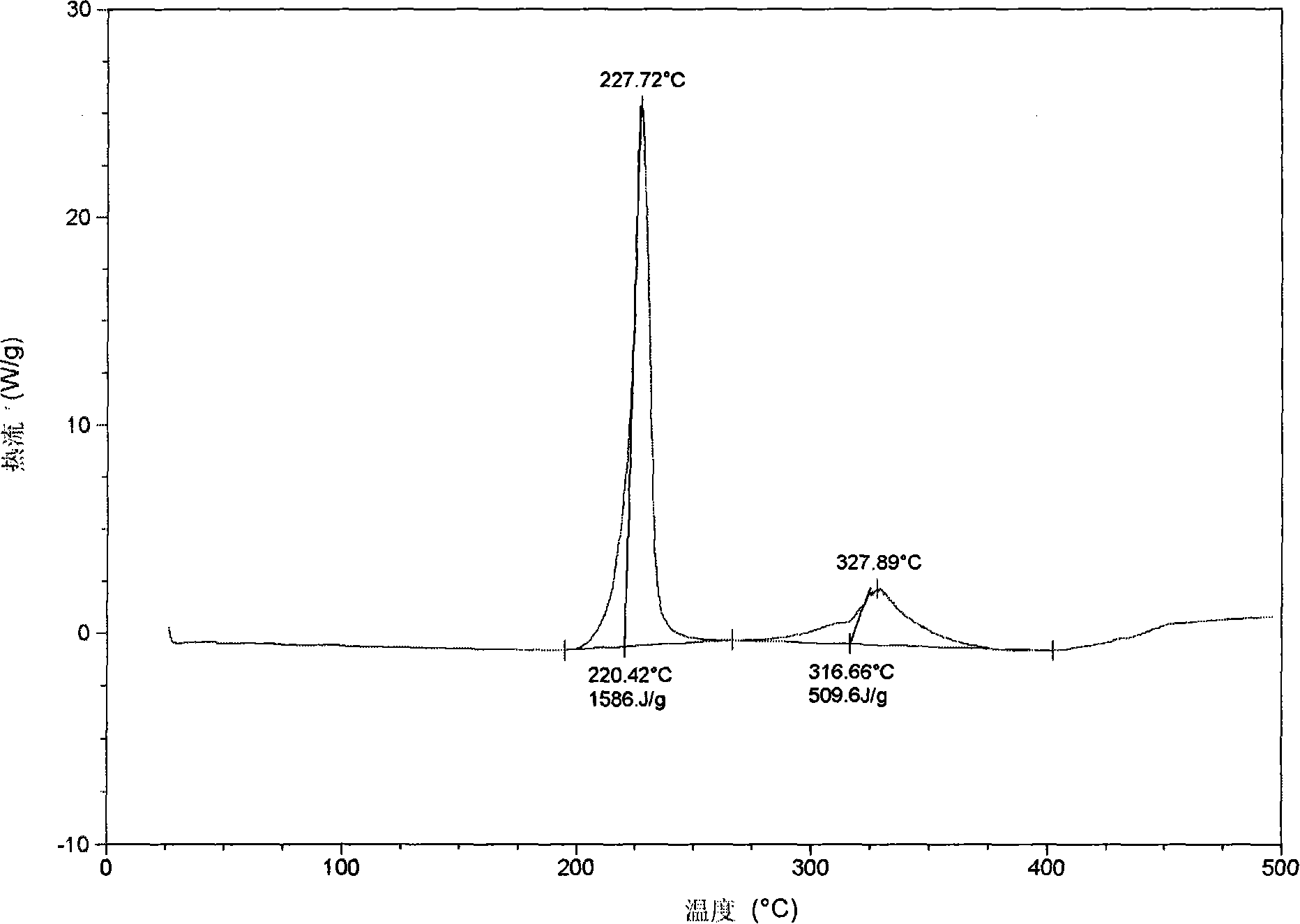

[0042] figure 1 Coordination environment diagram of potassium ions in the synthesized high-energy organopotassium salt; figure 2 It is the infrared spectrum of high-energy organic potassium salt; image 3 It is the DSC spectrum of the high-energy organic potassium salt. The DSC results show that the complex has high thermal stability and begins to decompose at about 200 ° C. The peak temperature is 227 ° C. The heat release is 2095 J / g, and the energy is relatively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com