Detection method for rapidly measuring micro trace quantity tin in ship hull steel by atomic fluorescence spectrometry

A rapid measurement technology of atomic fluorescence spectroscopy, which is applied in the field of special steel detection, can solve the problems of unapplicable and non-measurement of hull steel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

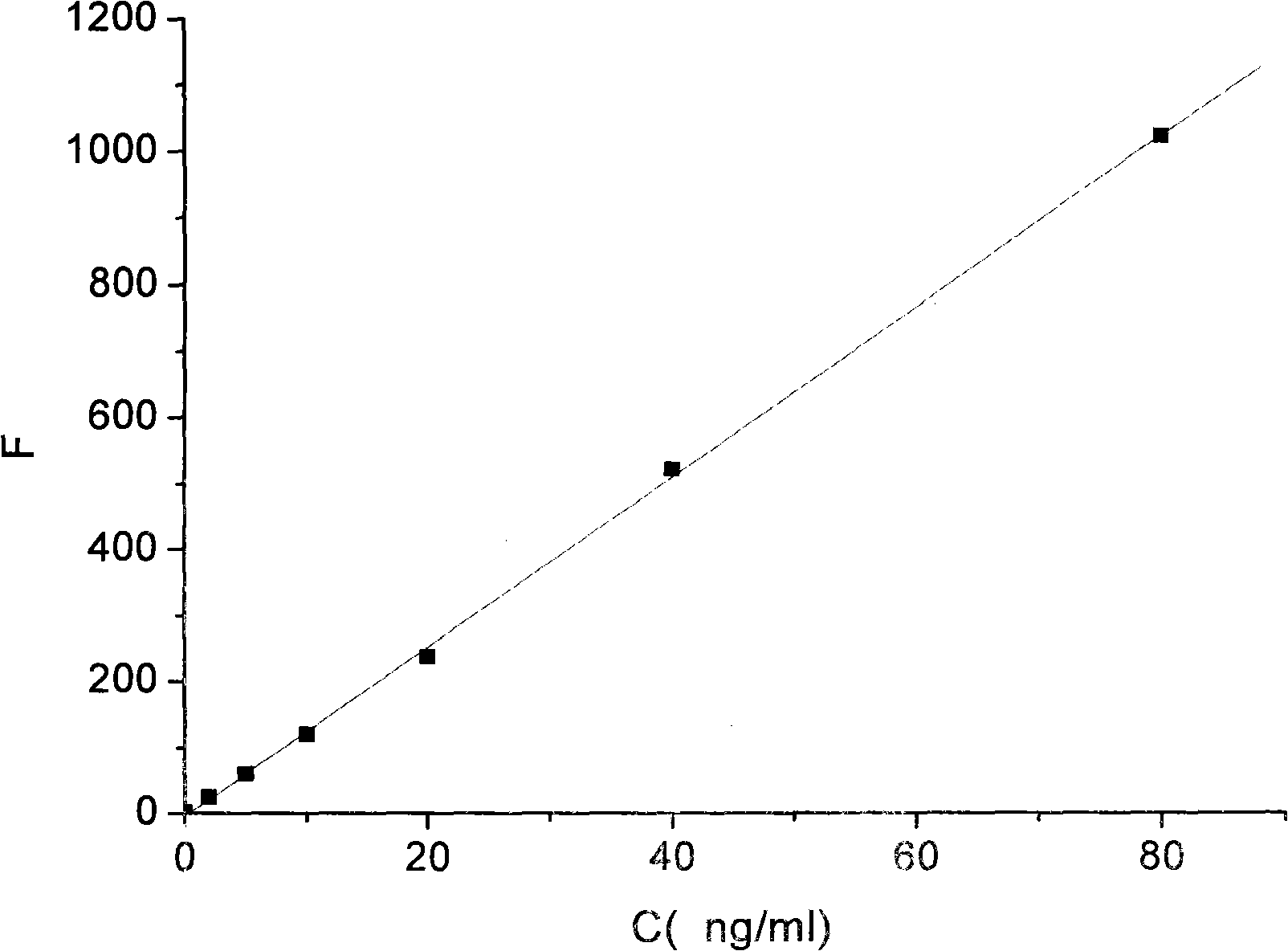

[0078] Weigh 0.1019g of the actual sample into a 100ml beaker, add 10ml of concentrated HCL, heat and dissolve on a hot plate, then add 2ml of concentrated HNO3, continue heating to a slight boiling state, evaporate until 1-2mL remains, remove and cool, Transfer to a 25ml volumetric flask, and dilute to the mark with 2% HCL. At the same time, make a sample blank. Under the working conditions selected by the instrument, measure the fluorescence intensity values of the blank, tin standard solution and sample respectively.

[0079] The test conditions are: negative high voltage 330V lamp current 90mA atomization height 6mm carrier gas flow 400ml / min shielding gas flow 600ml / min potassium borohydride 2% tartaric acid 5%, thiourea and ascorbic acid 0.8%.

Embodiment 2

[0081] Weigh 0.1050g of the actual sample into a 100ml beaker, add 10ml of concentrated HCL, heat and dissolve on a hot plate, then add 2ml of concentrated HNO3, continue heating to a slight boiling state, evaporate until 1-2mL is left, then remove and cool. Transfer to a 25ml volumetric flask, and dilute to the mark with 3% HCL. At the same time, make a sample blank. Under the working conditions selected by the instrument, measure the fluorescence intensity values of the blank, tin standard solution and sample respectively.

[0082] The test conditions are: negative high voltage 370V lamp current 50mA atomization height 8mm carrier gas flow 600ml / min shielding gas flow 900ml / min potassium borohydride 3.5% tartaric acid 3%, thiourea and ascorbic acid 2%.

Embodiment 3

[0084] Weigh 0.0990g of the real sample into a 100ml beaker, add 10ml of concentrated HCL, heat and dissolve on a hot plate, then add 2ml of concentrated HNO3, continue heating to a slight boiling state, evaporate until 1-2mL is left, remove and cool, Transfer to a 25ml volumetric flask, and dilute to the mark with 5% HCL. At the same time, make a sample blank. Under the working conditions selected by the instrument, measure the fluorescence intensity values of the blank, tin standard solution and sample respectively.

[0085] The test conditions are: negative high voltage 360V lamp current 70mA atomization height 7mm carrier gas flow 500ml / min shielding gas flow 700ml / min potassium borohydride 3% tartaric acid 4%, thiourea and ascorbic acid 1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com