Process for production of polyamide resin pellets for the production of films and polyamide resin films produced by using the same

A technology of polyamide resin and manufacturing method, applied in the field of polyamide resin film, can solve problems such as hindering productivity, and achieve the effects of improving productivity, less fish eyes, and high industrial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] 25 kg of caprolactam manufactured by Mitsubishi Chemical Corporation, 0.75 kg of water, and 1.74 g of disodium hydrogenphosphite pentahydrate were added to the container, and the gas atmosphere was replaced with a nitrogen atmosphere, followed by dissolution at 100°C. This raw material aqueous solution was transferred to the autoclave, and the jacket temperature was set to 280° C., and heating was started. The temperature of the contents was raised to 270°C, and then the pressure of the autoclave was slowly released, and then the pressure was further reduced until the set stirring power was reached, and the polycondensation reaction was terminated. After the reaction is terminated, the pressure is restored with nitrogen gas, and the content is introduced into the cooling water tank in the form of strands with a diameter of 2 mm, and then granulated to a length of 2-3 mm with a rotary cutter. The obtained granules and boiling water (1.5 times the amount of the granules) ...

Embodiment 2

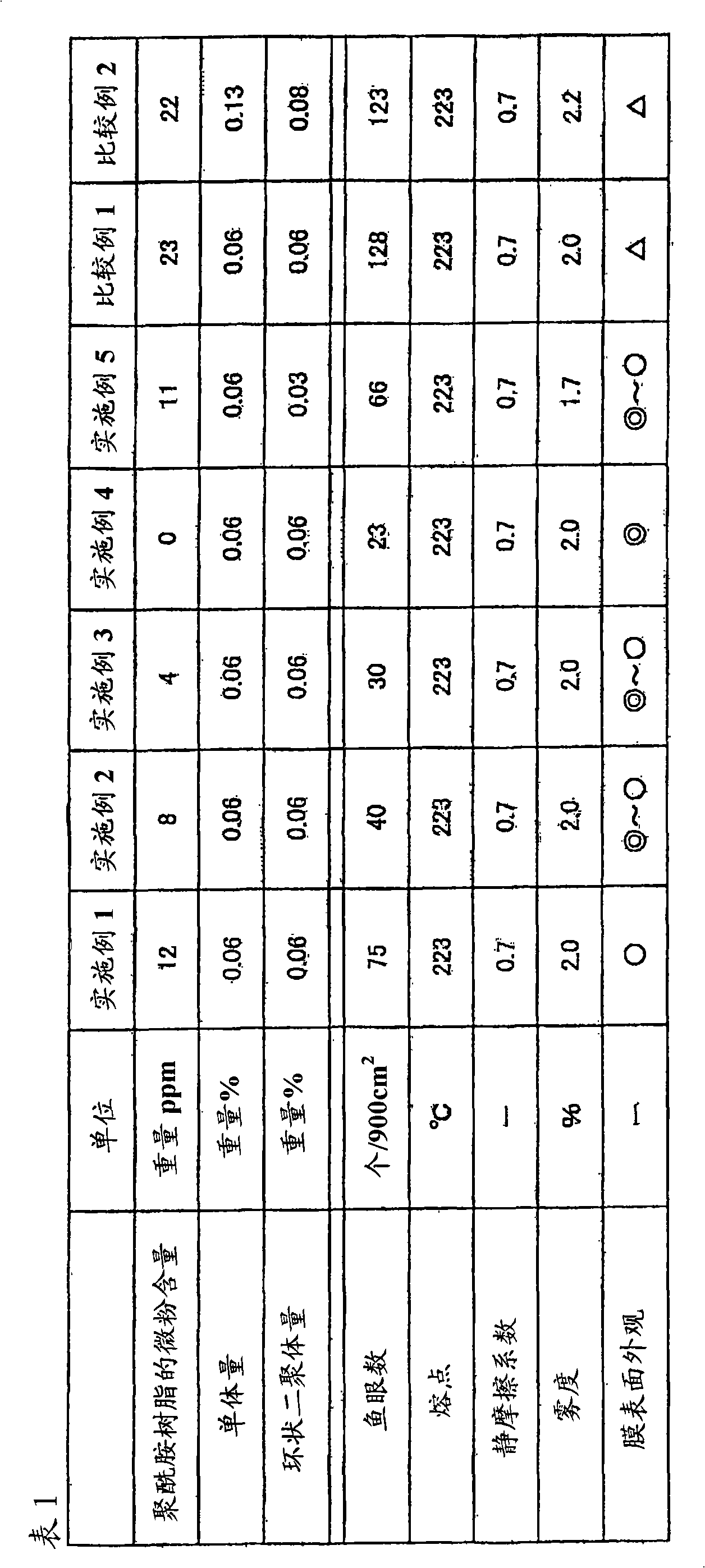

[0062] 400 g of a polyamide resin (with a fine powder content of 23 weight ppm) having a relative viscosity of 4.50 and 800 g of a polyamide resin having a relative viscosity of 4.50 from which fine powder has been removed were dry mixed to obtain a polyamide resin sample for evaluation, in the same manner as in Example 1. various evaluation methods. The evaluation results are shown in Table 1.

Embodiment 3

[0064] Various evaluations were carried out in the same manner as in Example 1, except that 200 g of a polyamide resin (with a fine powder content of 23 wt. Formula mixed, as a polyamide resin sample for evaluation, in the same manner as in Example 1, various evaluations were performed. The evaluation results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com