Method for producing good-quality high-carbon steel green rod for drawing

A technology of hot-rolled wire rod and production method, which is applied in the direction of metal rolling, metal rolling, workpiece surface treatment equipment, etc., and can solve the undisclosed process method, which is difficult to accurately control the number of sorbite and the size of the lamellar gap , poor comprehensive properties of pearlite, etc., to achieve the effect of reducing production costs, excellent comprehensive mechanical properties, and stable mechanical comprehensive properties

Inactive Publication Date: 2010-08-11

武钢集团有限公司

View PDF2 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The shortcomings of the above two production methods are: first, the interlamellar spacing of pearlite is greater than that of sorbite, and the comprehensive performance of pearlite is worse than that of sorbite; second, this method only proposes the average interlamellar interval λ and The relationship between the tensile strength Rm, but the process method for controlling the interlamellar gap of sorbite is not disclosed, and it is difficult to accurately control the amount of sorbite and the size of interlamellar interstitial in actual production

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

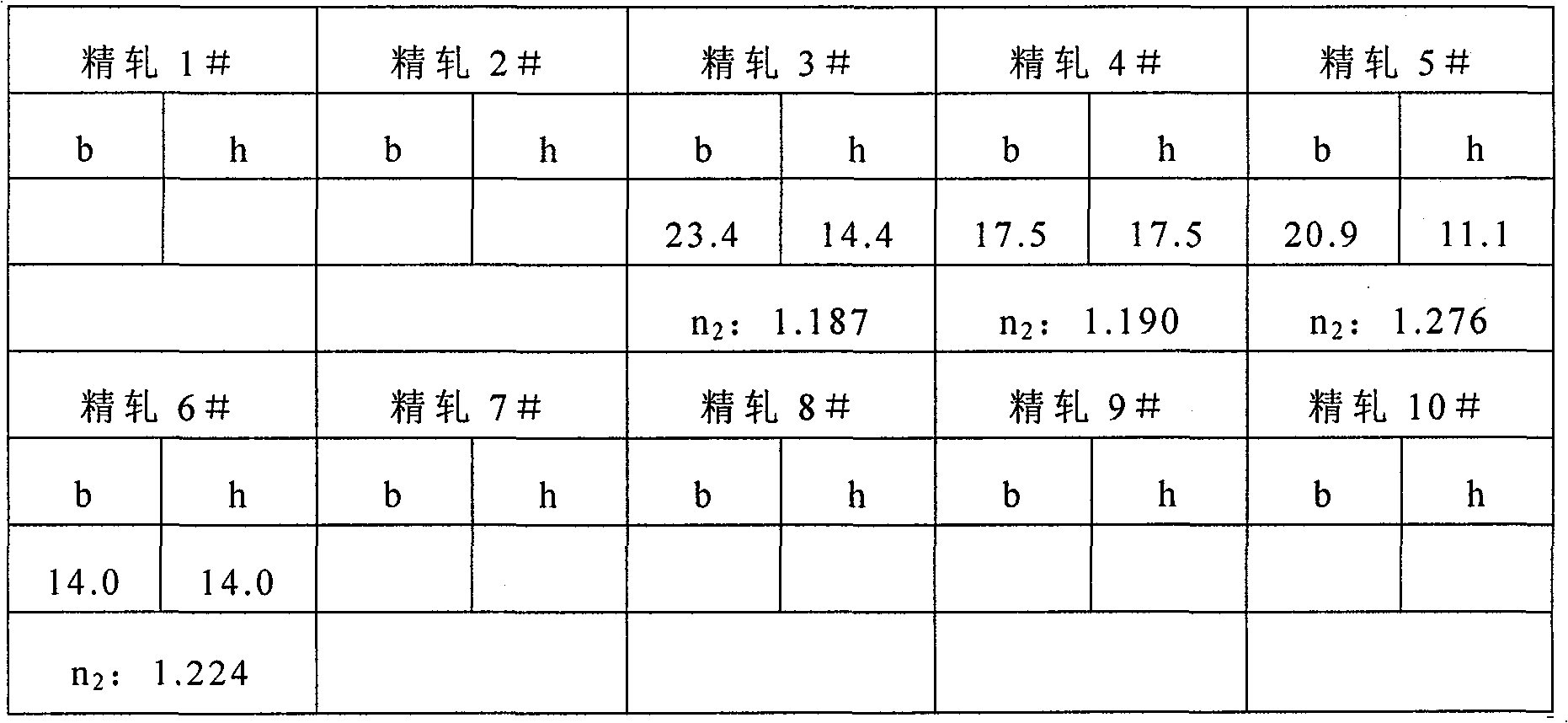

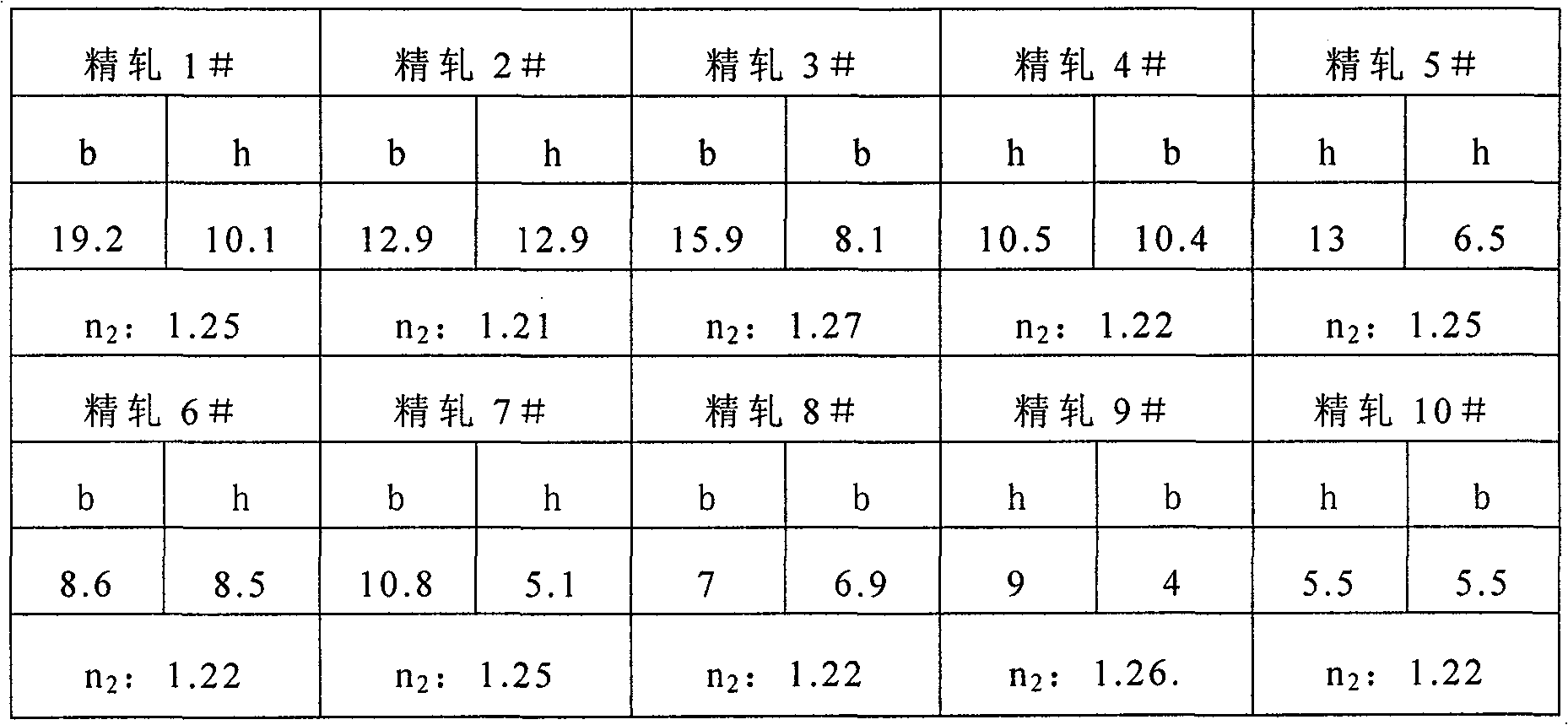

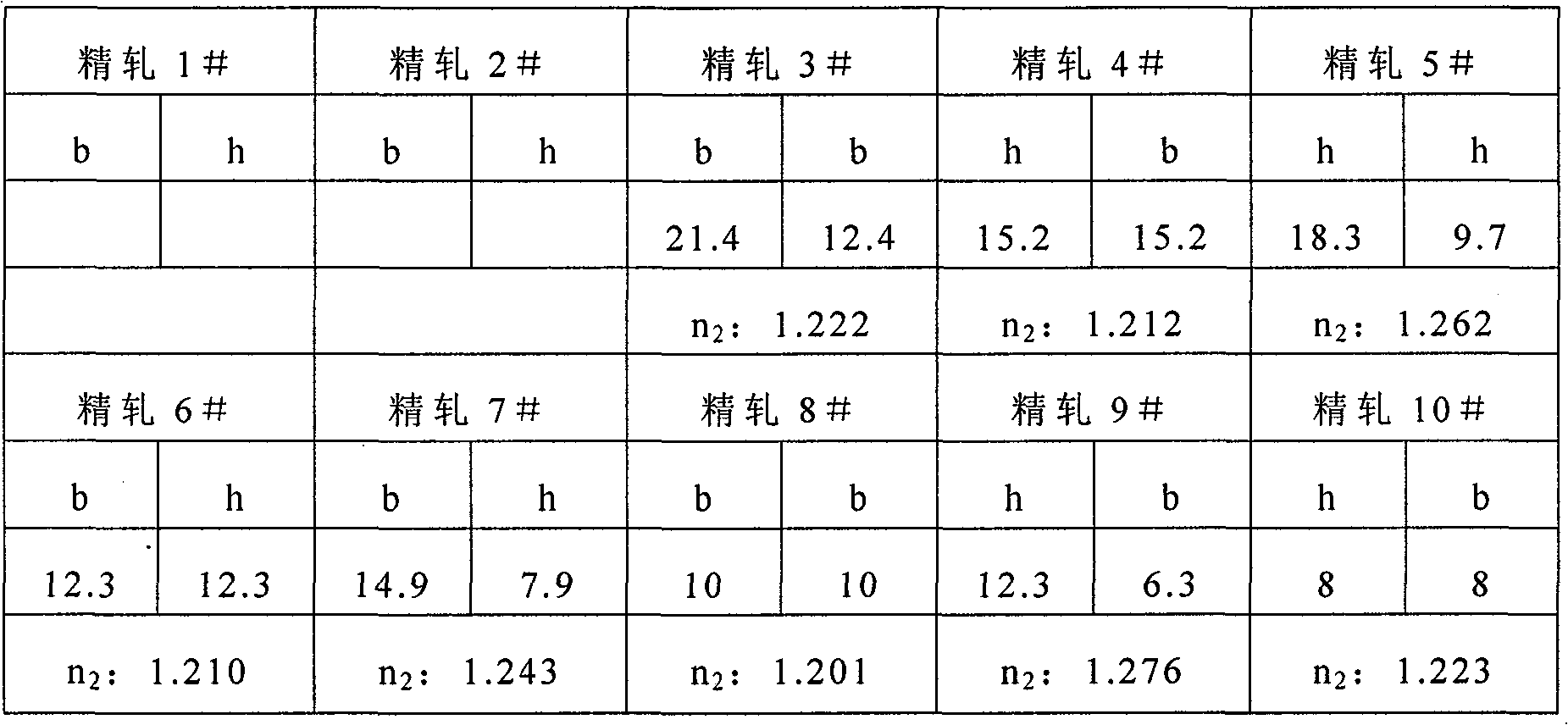

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a production method to draw high-quality high-carbon steel green rod, which includes the following steps: firstly, the high-carbon continuous cast steel is heated, and then goes through the treatment processes of rough rolling, medium rolling and prefinishing rolling so that the cumulative rolling elongation n1 equals 65 to 120 times; secondly, the rolled pieces are prewatercooled; and then the rolled pieces go through the prefinishing rolling process for 4 to 10 times, wherein, the elongation n2 equals to 1. 1 to 1. 3 times each time and the finishing temperature is 920 to 1090 degrees centigrade; and then the rolled pieces are prewatercooled for a second time, wherein, the rolled pieces reach a drawing out temperature of 830 to 900 degrees centigrade and are madeinto scattered rolls; in the end, the scattered rolls are air-cooled, wherein, the temperature of the scattered rolls at the outlet of the air cooling roll table is 330 to 450 degrees centigrade; therolls are cooled in the air environment to room temperature to produce high quality high-carbon steel green rods for drawing, which have large numbers of sorbites, small interlamellar spacing and stable mechanical properties and are not apt to brittle fracture in the production process.

Description

technical field The invention relates to the production and processing of steel wire rods, in particular to a production method of high-quality high-carbon steel hot-rolled wire rods for drawing. Background technique Carbon structural steel wire rods, especially high-quality high-carbon steel wire rods with a carbon content of 0.6-0.8%, are important raw materials for manufacturing screws, bolts, nuts, steel wires, wire ropes, drill bits, balls, welding rods, and spring steel wires. High-quality high-carbon steel wire rods with different needs and uses have different mechanical performance standards. The chemical composition, structure and grain size of steel play a decisive role in the mechanical properties of steel, especially for high-quality high-carbon steel wires drawn into different specifications of steel wires, not only require high strength, but also It is required to have good extensibility and toughness. For conventionally produced high-quality high-carbon ste...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B21B1/22B21B45/02B21B37/74

Inventor 陈庆丰严钢周新龙熊永强张青山谈知良熊玉彰杨友明吴卫明劭主彪张彦文

Owner 武钢集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com