Oil-contaminated water process method and mobile processing equipment thereof

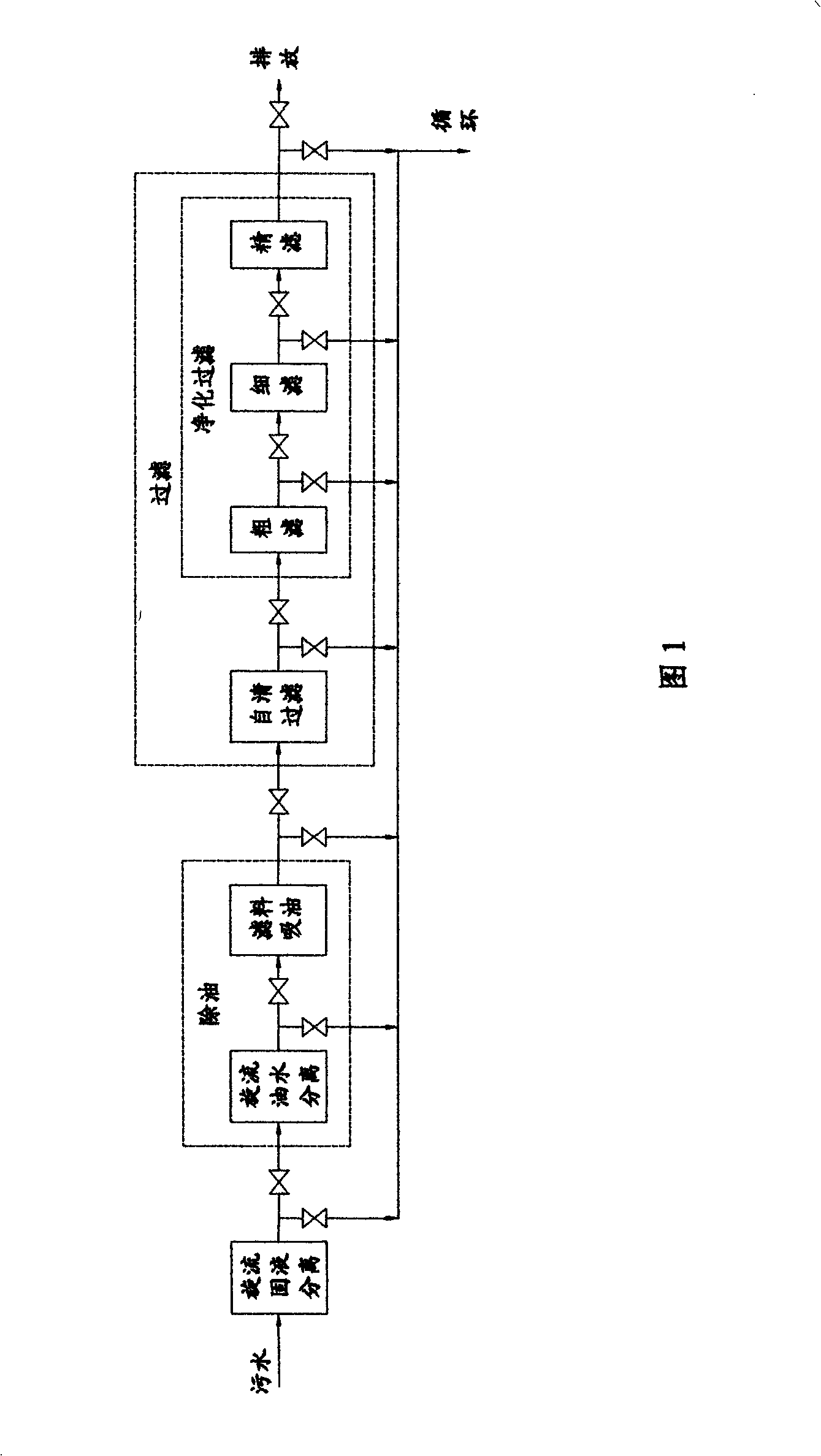

A technology for sewage treatment equipment and sewage treatment methods, which is applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, separation methods, etc., can solve problems such as large investment, and achieve convenient movement, good economy, and adaptability Strong effect of impact load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

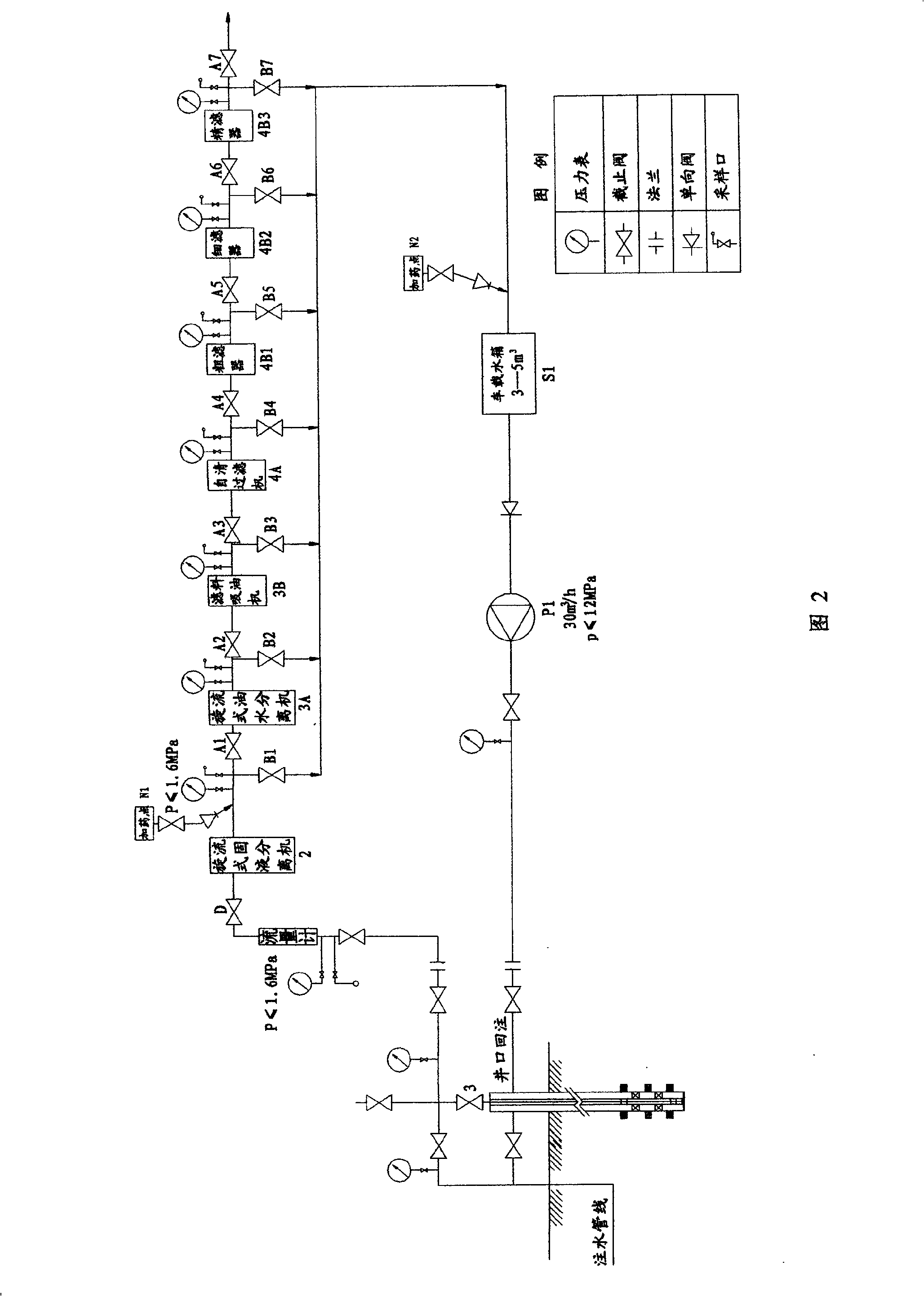

[0034] Embodiment 1, when it is applied to the treatment of flushing fluid of water injection wells in oilfields, the treatment flow is shown in Figure 2 in detail.

[0035] 1. Solid-liquid separation cycle process

[0036] Connect the output of the flushing fluid of the injection well to the input of the water purification vehicle, close the input valves A1, A2, A3, A4, A5 and A6, and the circulation valves B2, B3, B4, B5, B6 and B7, and open the system input Valve D and solid-liquid separation cycle valve B1.

[0037] The well flushing fluid in the water injection well enters the swirl type solid-liquid separator 2 through the system input valve D, basically separates the solids in the well flushing fluid, and enters the vehicle-mounted water tank S through the solid-liquid separation circulation valve B1. The circulating water in the vehicle-mounted water tank S is pressurized by the vehicle-mounted water injection pump P1 and reinjected into the water injection well, then...

Embodiment 2

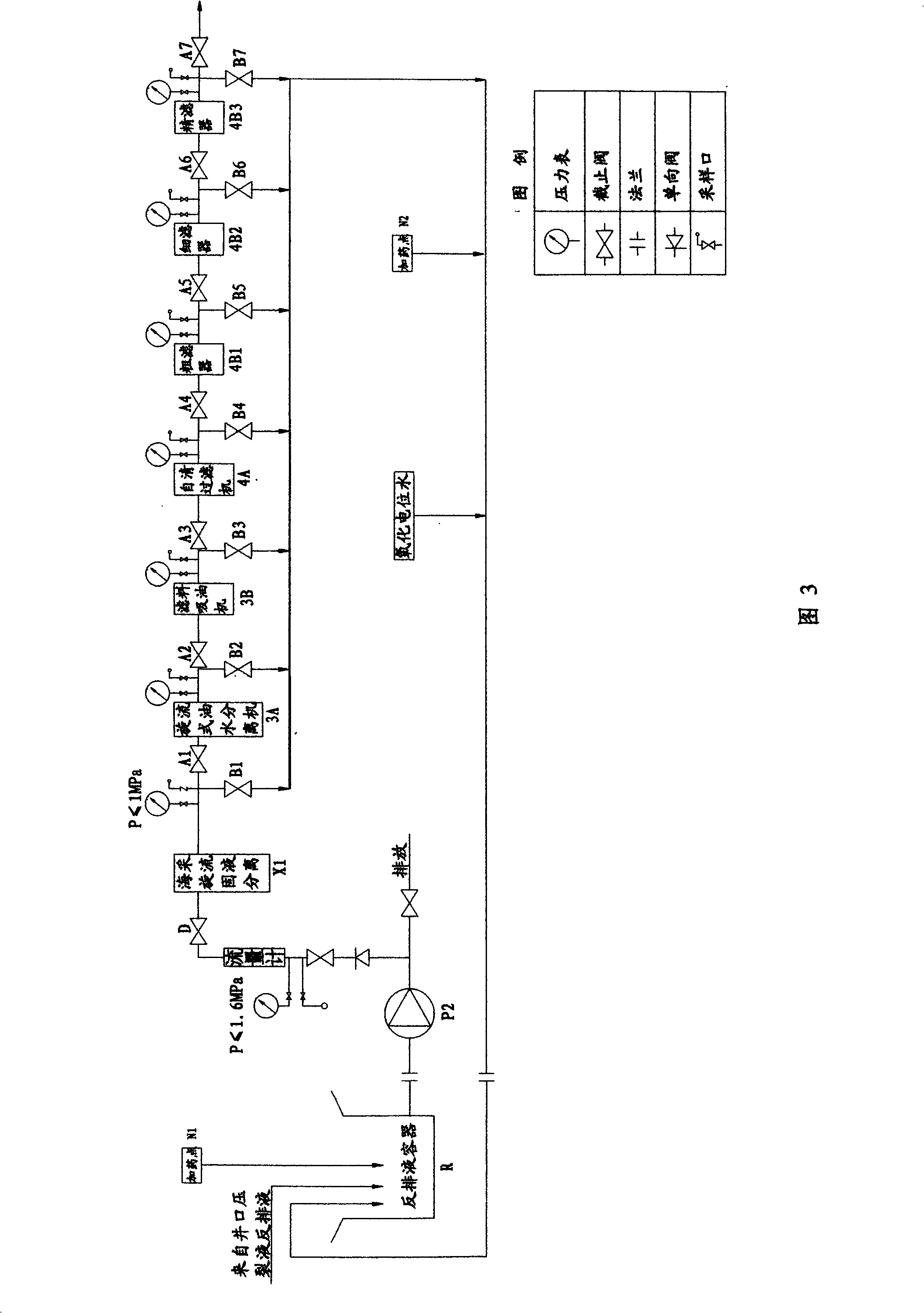

[0058] Embodiment 2, when it is applied to the treatment of oil field fracturing fluid reverse drainage, the treatment flow is shown in Fig. 3 in detail.

[0059] Fracturing has become one of the main measures to increase production in oilfields and is widely used in various oilfields. Especially in some old oilfield areas and peripheral oilfields. More than 2,500 to 3,000 fracturing operations are carried out every year, and each well requires a large amount of working fluid (fracturing fluid) to create fractures and carry sand during the fracturing process. After the construction work is completed, not only will the damage to the formation caused by fracturing be reduced, but the fracturing fluid (waste fluid) that breaks the gel after the fracture is closed should be flowed back in time, and the average flowback volume accounts for more than 50% of the total fluid volume. The composition of the flowback fracturing waste fluid system is extremely complex. In addition to the...

Embodiment 3

[0065] Embodiment 3, when it is applied to on-site drinking water production in flood-stricken areas, the processing flow is shown in Figure 4 for details.

[0066] This embodiment is different from the processing flow of Embodiment 2 in that:

[0067] Open the input valves D, A1, A2, A3, A4, A5 and A6 of the water purification vehicle, and the system circulation valve B7, close the circulation valves B1, B2, B3, B4, B5 and B6, and the discharge valve A7.

[0068] The vehicle-mounted infusion pump P2 pumps the sewage in the disaster area into the treatment system, and sends it to the swirl type solid-liquid separator 2, and the sequentially connected swirl type oil-water separator 3A, filter material oil suction unit 3B, self-cleaning filter 4A, coarse Filter 4B1, fine filter 4B2 and fine filter 4B3 are processed.

[0069] After the treated water is disinfected, it enters the vehicle-mounted water tank S or the ground water storage tank for on-site drinking.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap