Formula for synthesizing crosstie and continuous forming process

A molding process and sleeper technology, applied in the direction of track, ballast layer, construction, etc., can solve the problems of inconvenient continuous operation, unstable product performance, low production efficiency, etc., achieve light weight, excellent mechanical properties, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

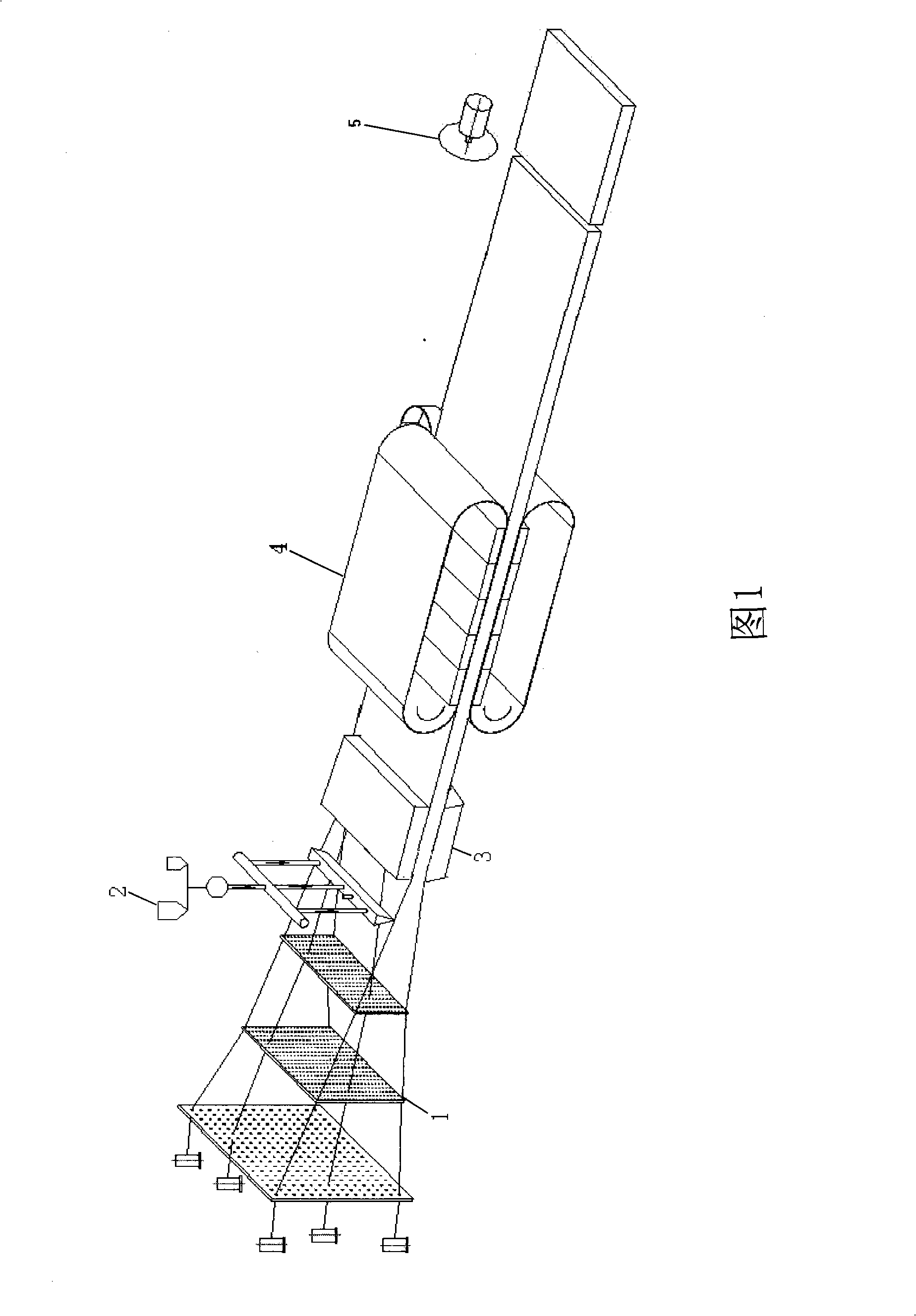

Image

Examples

Embodiment 1

[0027] Polyurethane resin foam formula: polyether polyol 1 (number of hydroxyl groups is 3-8, molecular weight below 1300) 90, polyether polyol 2 (number of hydroxyl groups is 2-3, molecular weight is 2000-4000) 10, catalyst 0.01 , hard foam silicone oil 0.5, blowing agent 0.2, flame retardant 5, anti-aging agent 0.1, isocyanate 200.

[0028] Continuous molding process parameters: running speed 0.3m / min

[0029] Pouring rate 3kg / min

[0030] The total length of the forming mold is 20m

[0031] Forming mold section 230mm×70mm

[0032] Molding temperature 80℃

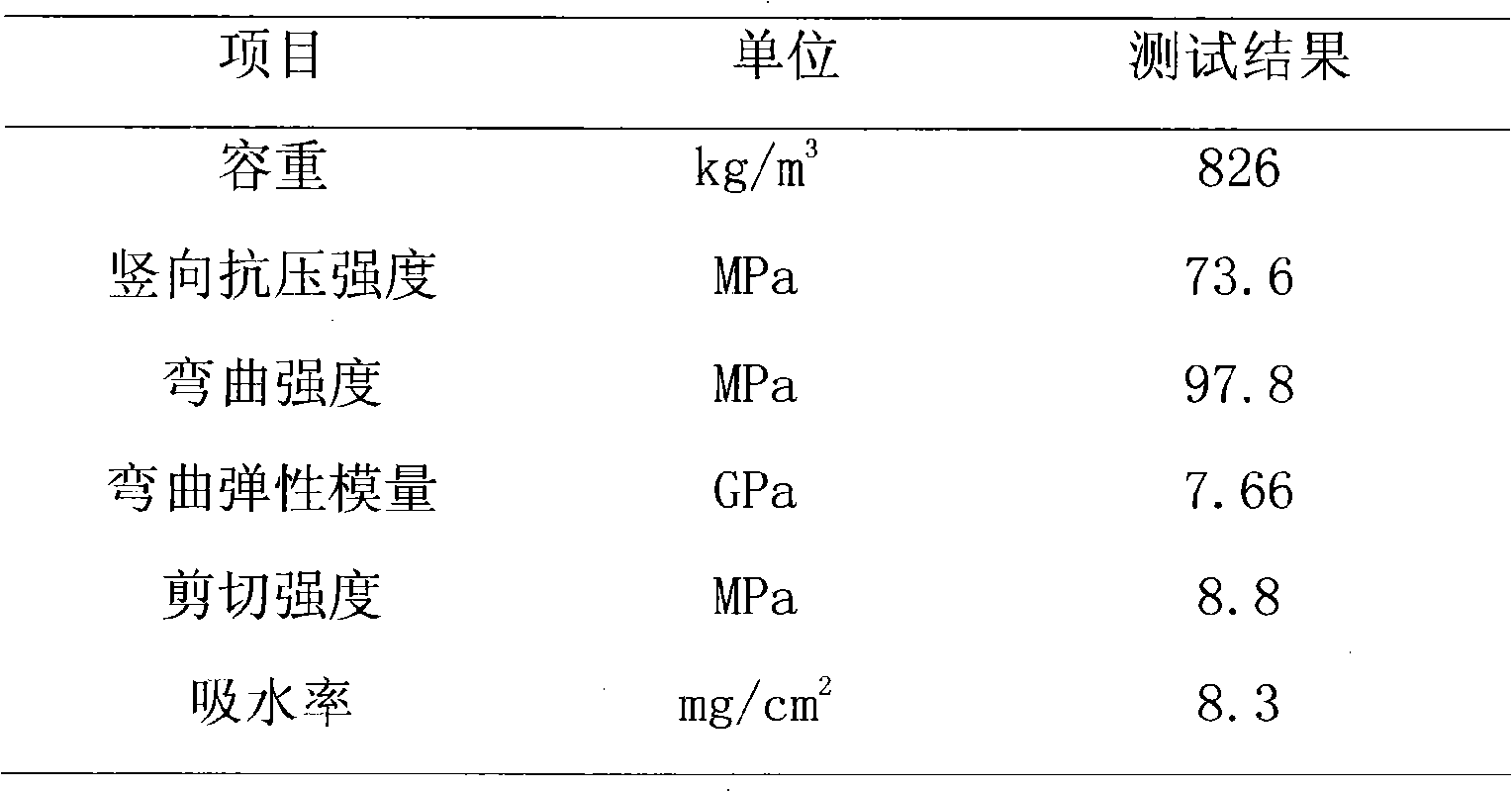

[0033] According to the continuous molding process of the present invention, the properties of the synthetic sleepers prepared after setting the above parameters are shown in the following table.

[0034]

Embodiment 2

[0036] Polyurethane resin foaming material formula: polyether polyol 1 (number of hydroxyl groups is 3-8, molecular weight below 1300) 80, polyether polyol 2 (number of hydroxyl groups is 2-3, molecular weight is 2000-4000) 20, catalyst 0.05 , hard foam silicone oil 2, blowing agent 0.5, flame retardant 15, anti-aging agent 0.3, isocyanate 160.

[0037] Continuous molding process parameters: running speed 0.5m / min

[0038] Pouring rate 4kg / min

[0039] The total length of the forming mold is 20m

[0040] Forming mold section 200mm×100mm

[0041] Molding temperature 80°C

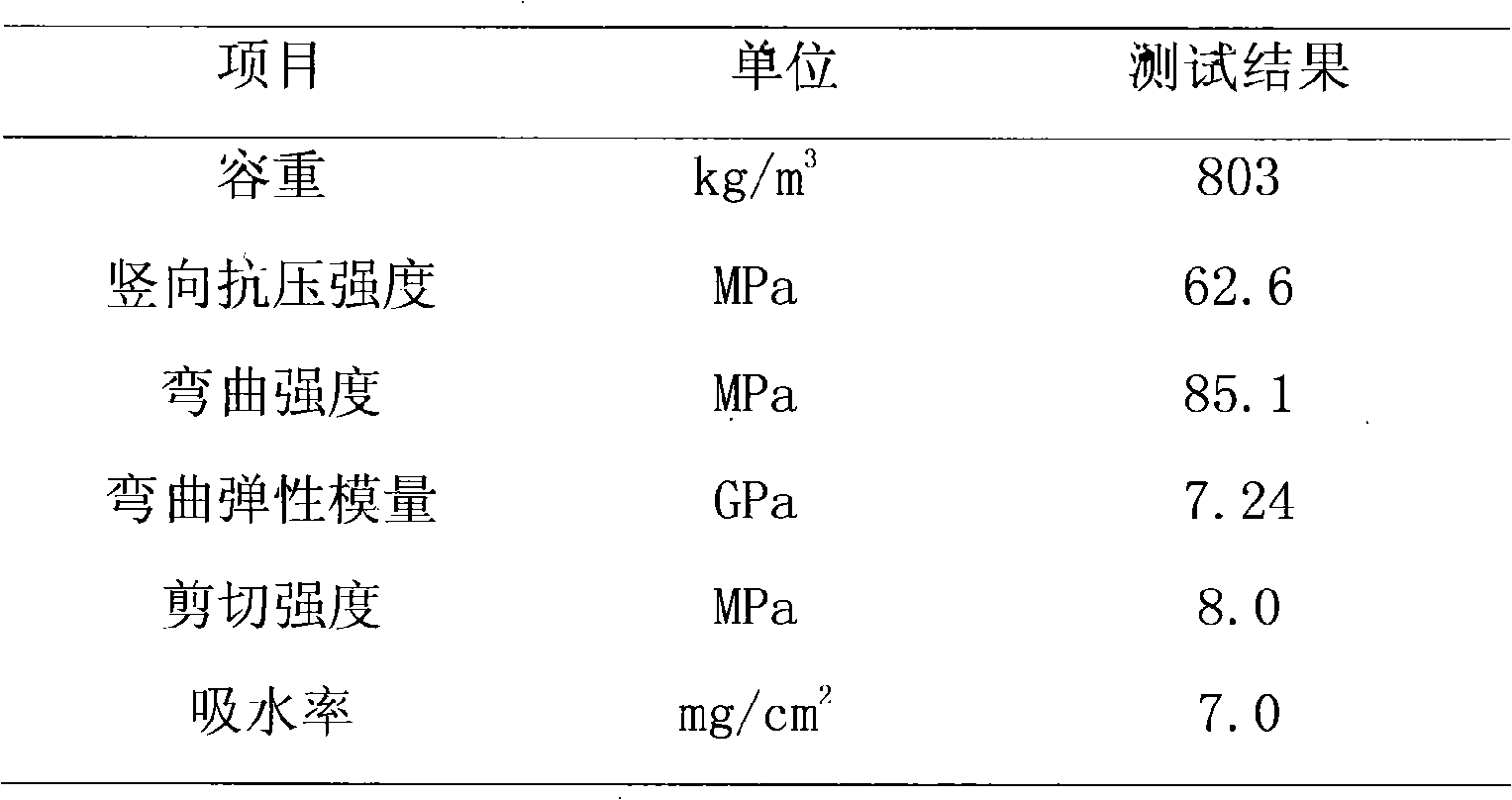

[0042] According to the continuous molding process of the present invention, the properties of the synthetic sleepers prepared after setting the above parameters are shown in the following table.

[0043]

Embodiment 3

[0045] Polyurethane resin foam formula: polyether polyol 1 (number of hydroxyl groups is 3-8, molecular weight below 1300) 60, polyether polyol 2 (number of hydroxyl groups is 2-3, molecular weight is 2000-4000) 40, catalyst 0.1 , hard foam silicone oil 3, foaming agent 1.0, flame retardant 25, anti-aging agent 0.5, isocyanate 115.

[0046] Continuous molding process parameters: running speed 0.8m / min

[0047] Pouring rate 6.4kg / min

[0048] The total length of the forming mold is 20m

[0049] Forming mold section 210mm×80mm

[0050] Molding temperature 80°C

[0051] According to the continuous molding process of the present invention, the properties of the synthetic sleepers prepared after setting the above parameters are shown in the following table.

[0052]

[0053] In above-mentioned three embodiments, after its respective polyurethane resin foam formula and continuous molding process parameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com