Deoxidant and process for producing deoxidant

A manufacturing method and technology of deoxidizer, which are applied in the field of deoxidizer, can solve the problems of cerium oxide being easy to catch fire, insufficient oxygen absorption capacity, and insufficient performance of deoxidizer, so as to prevent fire caused by violent reaction with oxygen, and have good oxygen absorption effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0060] Next, the deoxidizer according to the first embodiment of the present invention will be described.

[0061] The deoxidizer of the first embodiment of the present invention is made of cerium oxide (CeO x , wherein, x is a positive number less than 2) formed, and the specific surface area is 0.6m 2 The powder below / g or the specific surface area is 3.0m 2 / g or less molded body.

[0062] Such a deoxidizer according to the present embodiment reacts with oxygen in the atmosphere as shown in the following chemical formula (2).

[0063] CeO x +((2-x) / 2)O 2 →CeO 2 (2)

[0064] That is, the above-mentioned high-temperature reduction-treated cerium oxide (CeO x , wherein, x is a positive number less than 2) oxygen is removed from the crystal lattice by reduction treatment to form an oxygen vacancy state. Because it reacts with oxygen in the atmosphere as shown in the above-mentioned chemical formula (2), it can exert an effect as a deoxidizing agent.

[0065] Here, as ...

no. 2 Embodiment approach

[0078] Next, a deoxidizer according to a second embodiment of the present invention will be described.

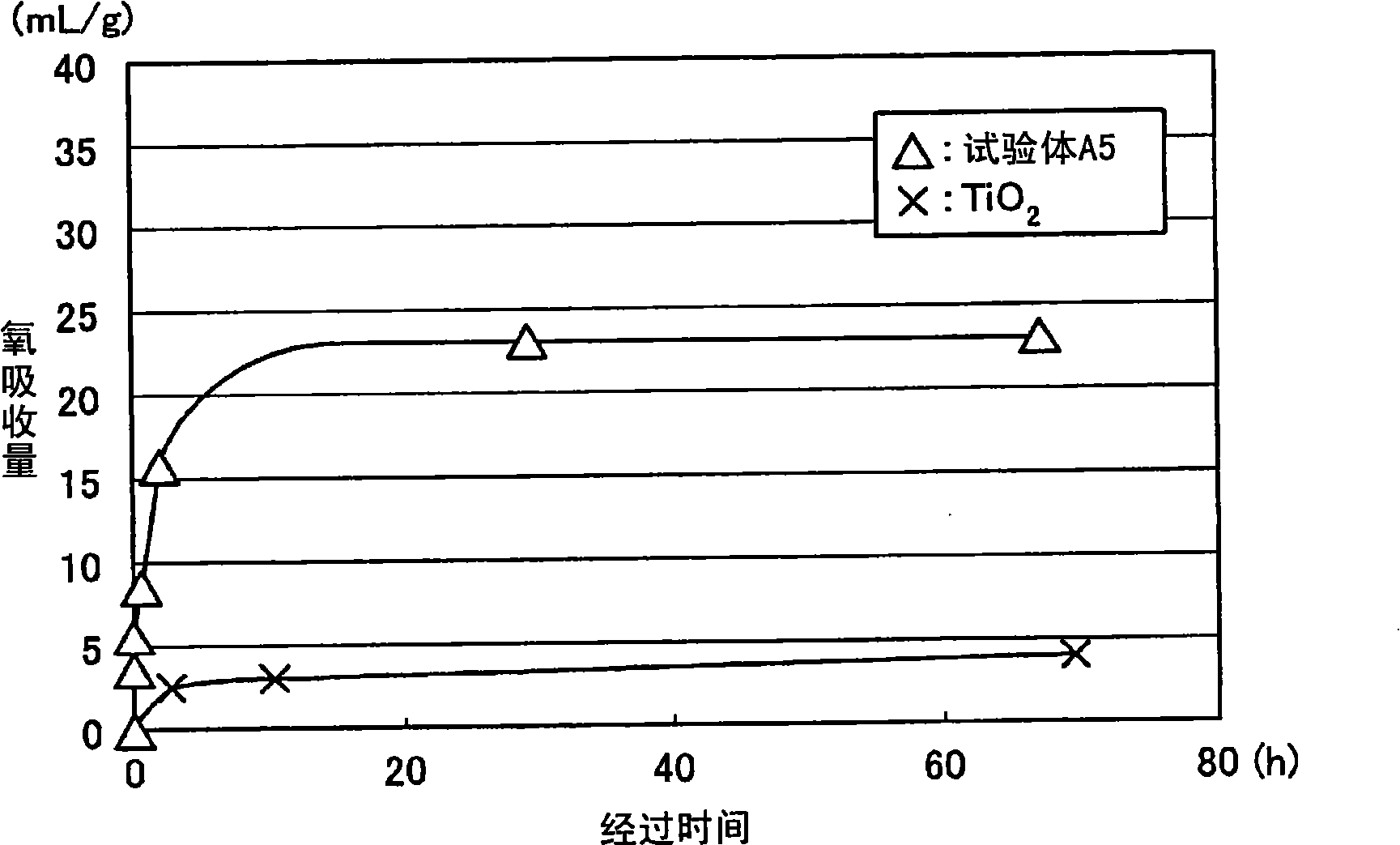

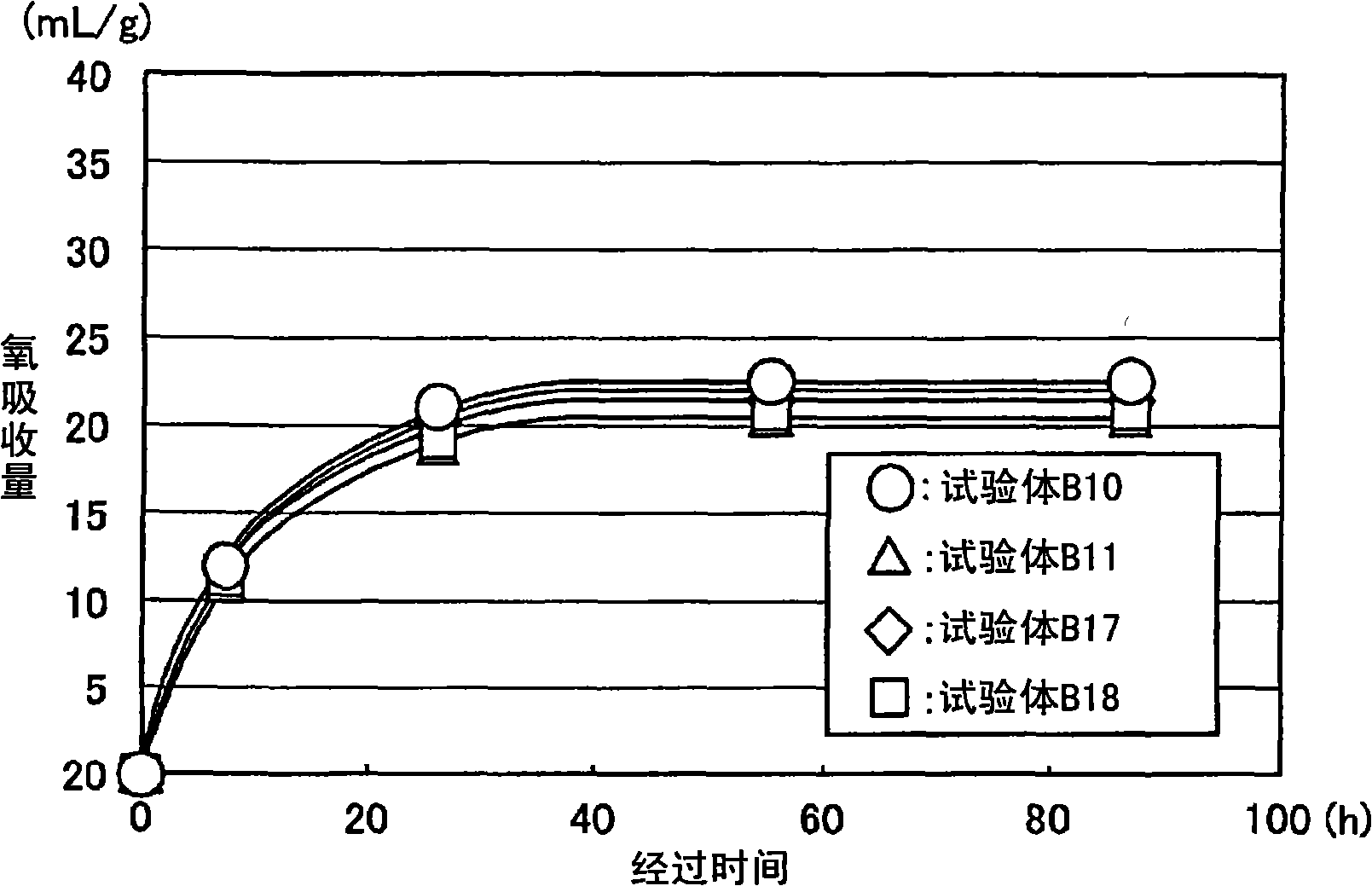

[0079] The deoxidizer according to the second embodiment of the present invention is a deoxidizer that absorbs and removes oxygen in the atmosphere, and the deoxidizer is an inorganic oxide having oxygen vacancies, and an additive element that increases the oxygen absorption amount of the inorganic oxide is added.

[0080] Here, in the present invention, the inorganic oxide may be any one of cerium oxide, titanium oxide, zinc oxide, etc., or a mixture thereof.

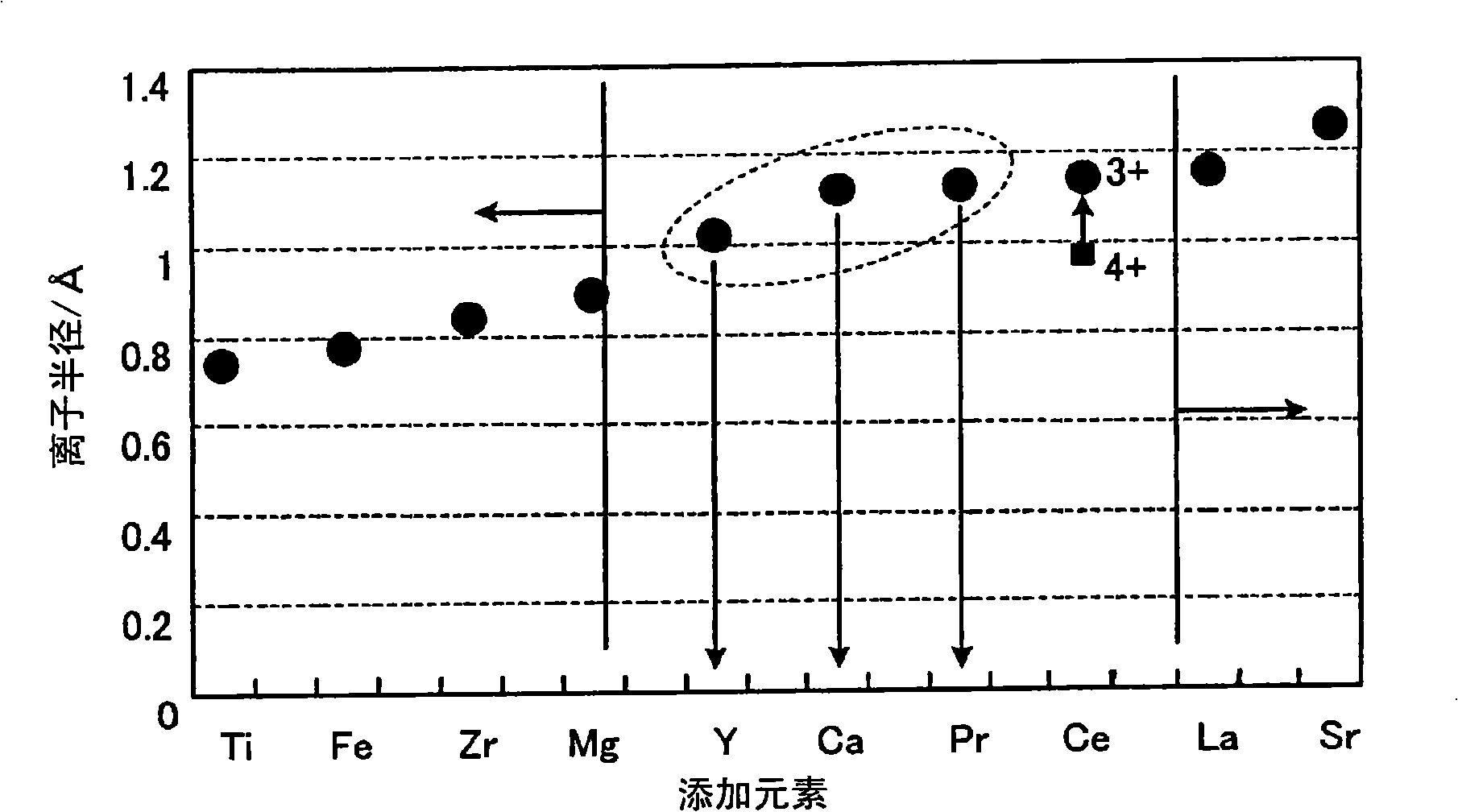

[0081] It is particularly preferable to use cerium oxide, which has a large oxygen absorbing capacity when used alone, as the inorganic oxide. As an additional element to be added to the inorganic oxide, it is preferable to add an element near the ionic radius of the inorganic oxide, but there is no limitation as long as the oxygen absorption amount can be increased by adding a substance.

[0082] Here, in this emb...

no. 3 Embodiment approach

[0103] In addition, if Figure 8 As shown, the deoxidizers of the above-mentioned first embodiment and second embodiment can also be deoxidized by the cerium oxide having a predetermined specific surface area or an inorganic oxide added with an element that increases the oxygen absorption amount. Layer 11, a gas barrier layer 12 provided on the outer layer side of the deoxygenation absorbing layer 11 and having gas barrier properties, a gas permeable layer provided on the inner layer side of the deoxygenation absorbing layer 11 and having gas permeability 13 constitutes the deoxidation function film 10. here, Figure 8 In , symbol 15 represents oxygen.

[0104] in addition, Figure 8 Among them, the outer side of the gas barrier layer 12 is provided with an outer layer 14 to protect the gas barrier layer.

[0105] Here, examples of the gas barrier layer 12 include aluminum foil, polyethylene terephthalate (PET), polyethylene (PE), stretched polypropylene (PP), polyvinyl al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com