Oscillation welding method under the effect of magnetic lens and magnetic lens device

A welding method and magnetic lens technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of small adjustment range of magnetic field intensity, imperfect influence device, inability to adjust magnetic field distribution, etc., so as to improve welding quality, Easy to operate, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

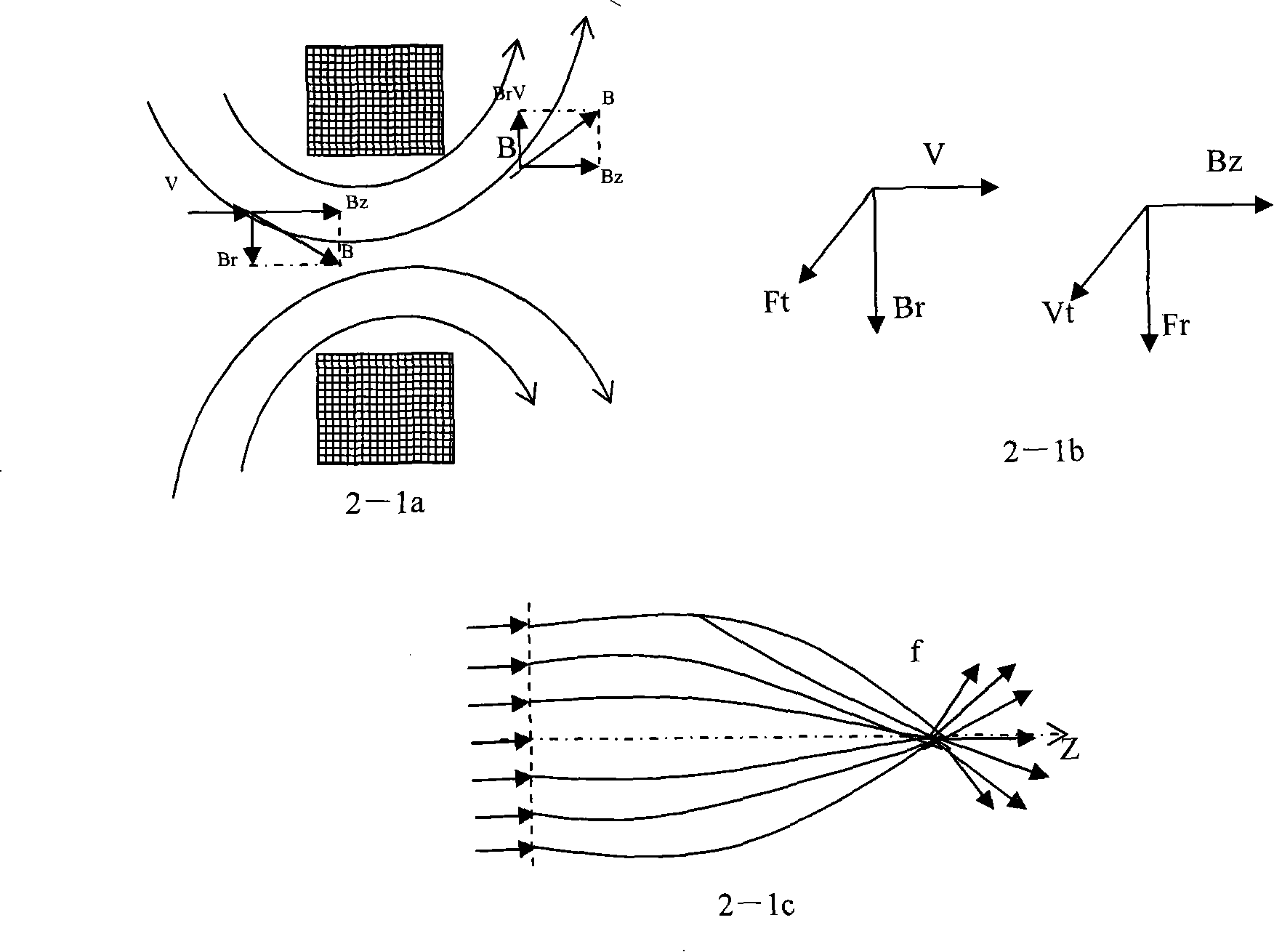

[0023] Embodiment 1: The oscillation welding method under the action of a magnetic lens is to control the welding arc through an external magnetic field, which affects the shape of the arc, droplet transfer and welding pool, thereby affecting the welding process and improving the welding process. Its characteristics are: AC TIG welding is adopted, the magnetic field is the static magnetic field generated by permanent magnets, and the bipolar shoe magnetic lens is used to effectively control the welding process and improve the welding shape. The welding effect can be seen in Figure 4 ,Depend on Figure 4 It can be seen that when electromagnetic oscillation is applied, the grain structure changes from the original coarse columnar crystals to fine equiaxed crystals.

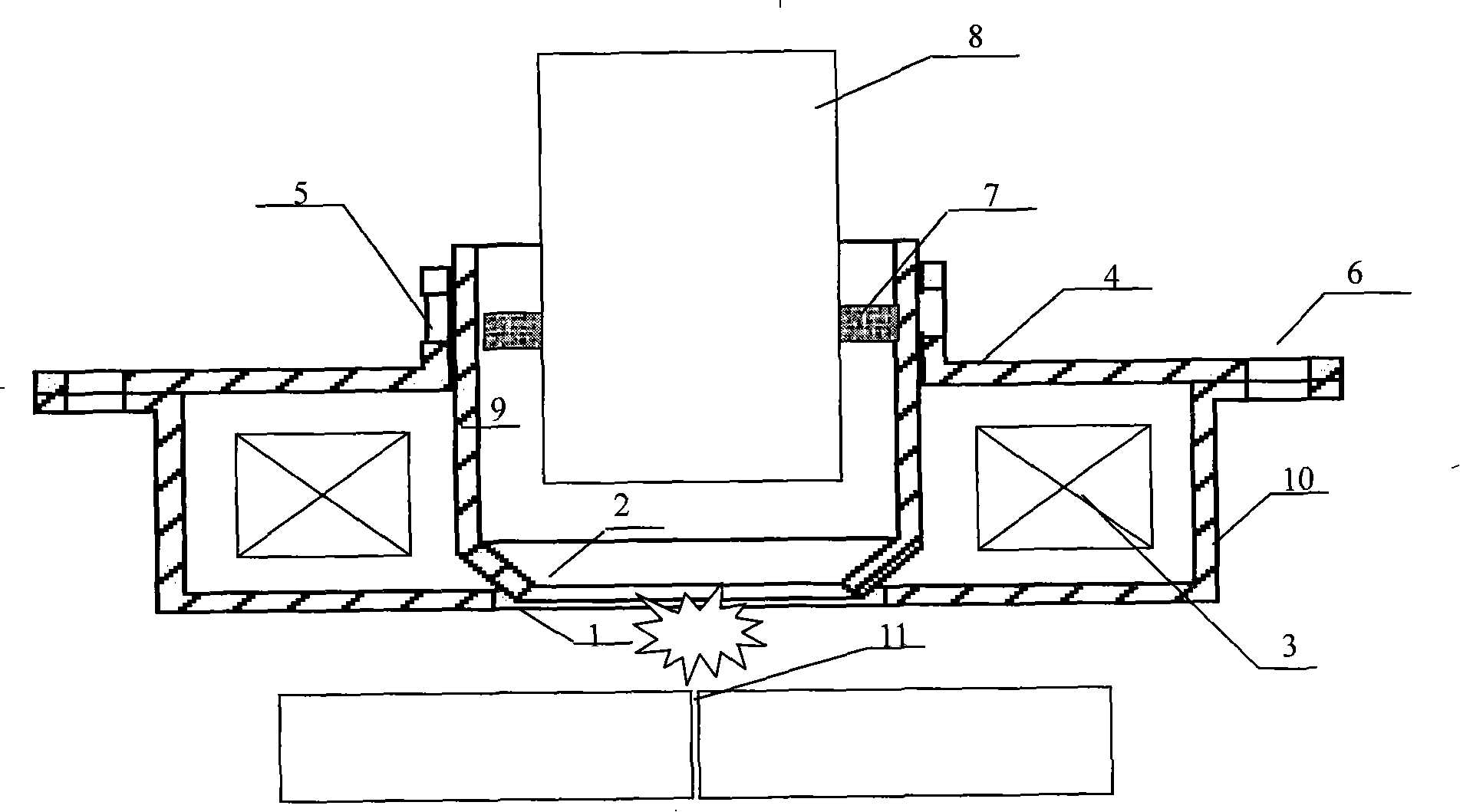

[0024] The bipolar shoe magnetic lens used in this example is mounted as figure 1 As shown, it includes a welding torch 8 and a coil 3 positioned directly above the welding seam 11, the welding torch 8 is locate...

Embodiment 2

[0025] Embodiment 2: This embodiment is basically the same as the above embodiment, the difference is: DC welding is adopted, a negative alternating magnetic field is applied, and a single-pole shoe magnetic lens device is used.

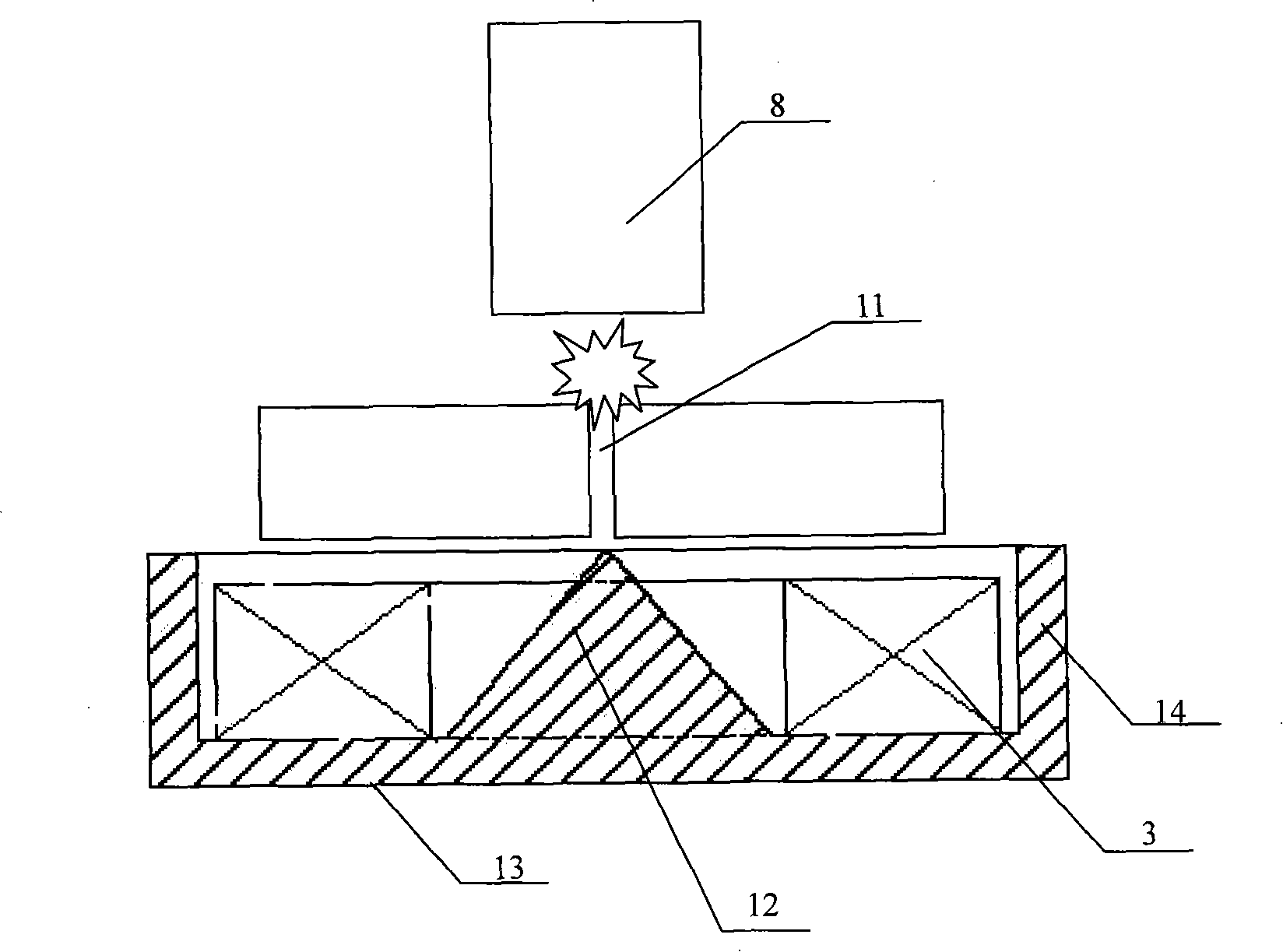

[0026] The monopole shoe magnetic lens device adopted in this embodiment is as image 3 As shown, it includes a welding torch 8 and a coil 3 positioned directly above the weld seam 11. The coil 3 is placed on a magnetic field bottom plate 13 directly below the weld seam 11. There is an annular magnetic field side plate 14 on the periphery. A tapered pole shoe 12, the tapered point of which is aligned with the weld seam 11, and the lower end is integrated with the magnetic field bottom plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com