Method for nonoxidizing heating thin steel plate and special heating furnace

A technology of non-oxidation heating and thin steel plates, which is applied in the field of metallurgical industrial furnaces, can solve the problem that the heating thin steel plates cannot be guaranteed to be 100% free from oxidation, and achieve the effects of reducing equipment maintenance, reducing length and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] An embodiment of the method for non-oxidative heating of thin steel plates in the present invention is a method for heating thin steel plates by blowing high-temperature inert gas directly onto the thin steel plates. It uses a direct blowpipe to directly blow high-temperature inert gas to the thin steel plate in the furnace, and the temperature of the high-temperature inert gas is 1100°C-1200°C. The high-temperature inert gas is one or a combination of helium, neon, argon, krypton, xenon, and nitrogen. In this embodiment, a single argon is used, and the purity of the high-temperature inert gas is above 99.9%. The pressure of the high-temperature inert gas in the direct blowpipe is 10KPa±1KPa; the working flow rate of the high-temperature inert gas in the direct blowpipe is: 0.8-3m 3 / minute.

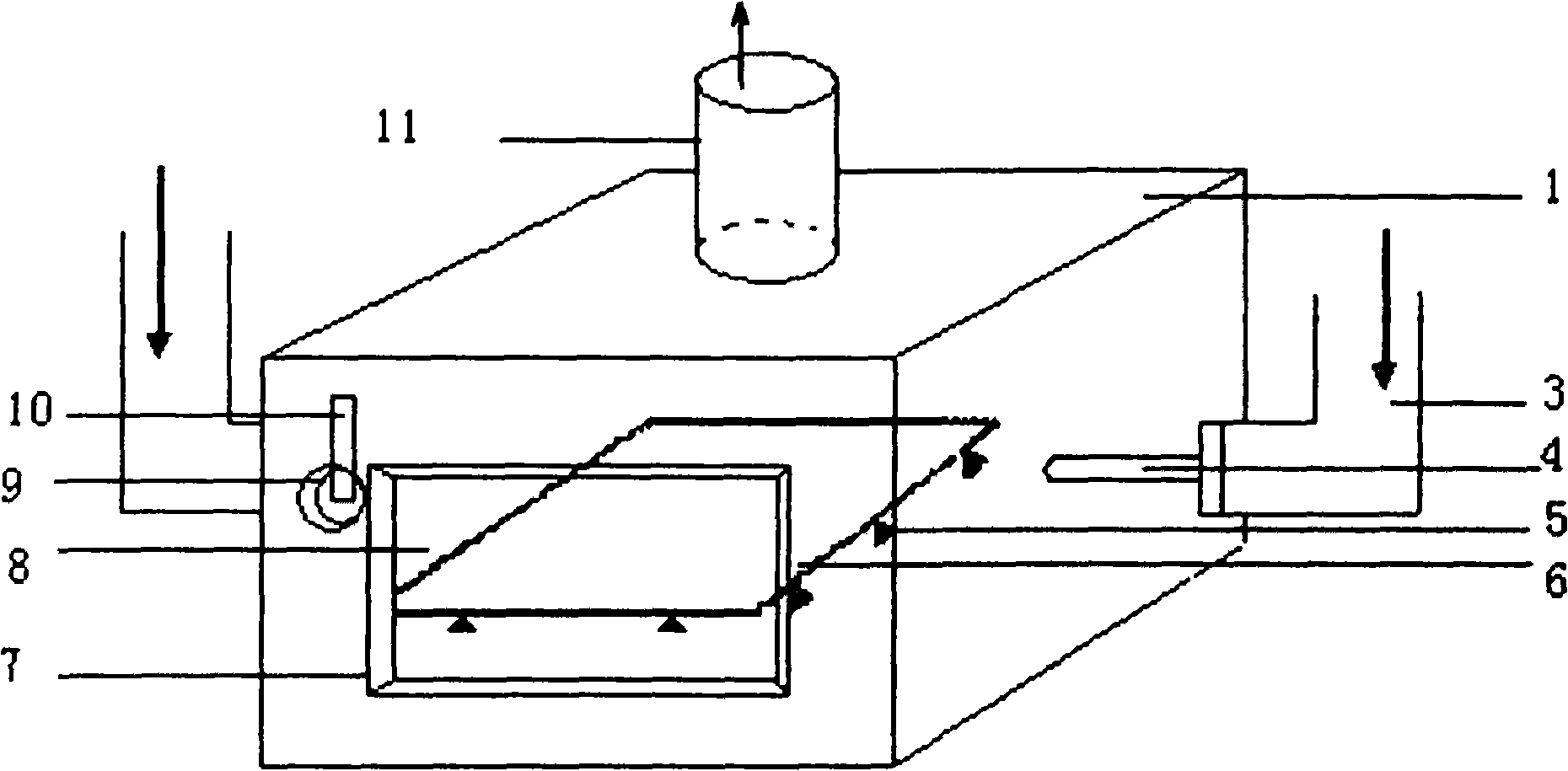

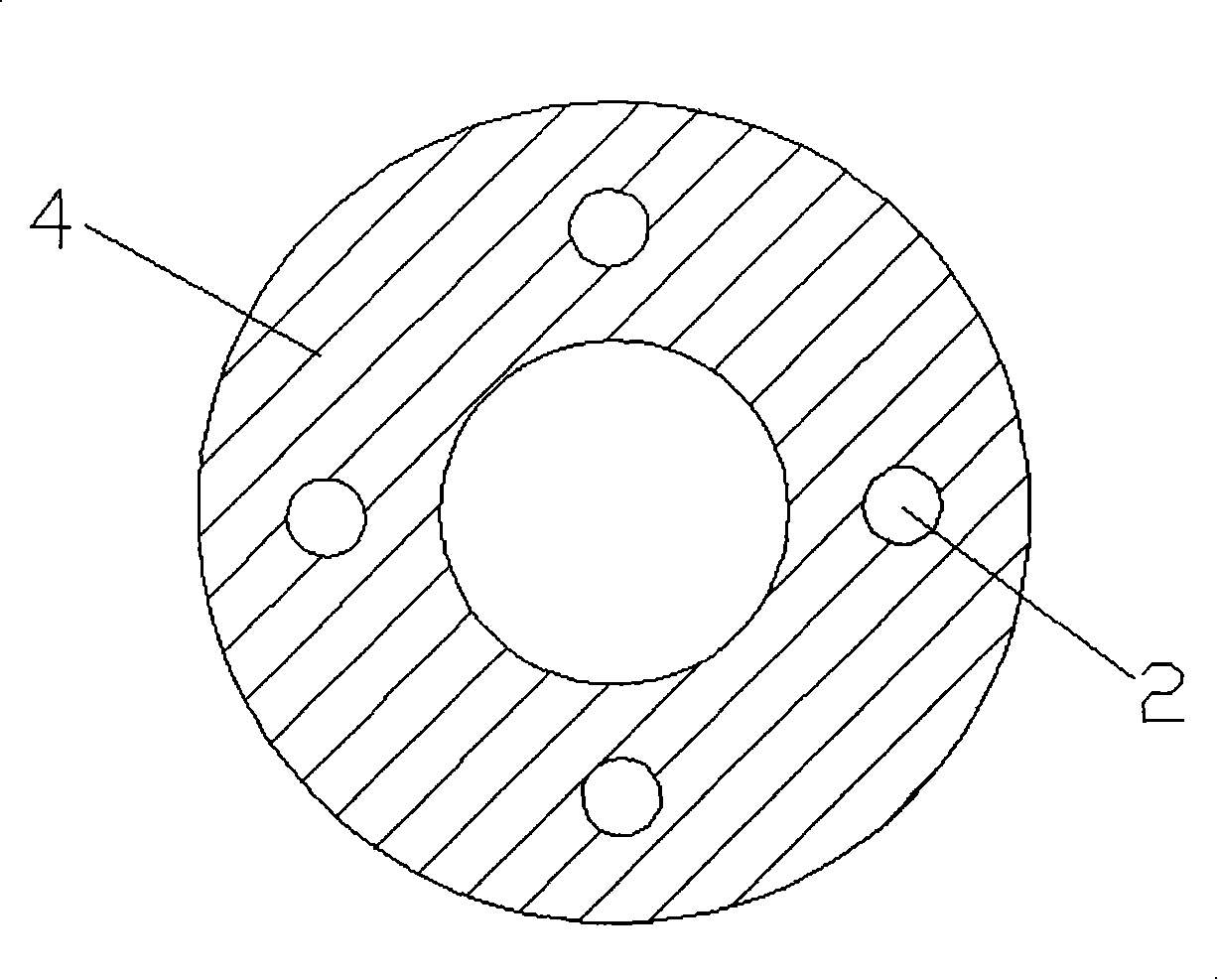

[0028] Such as figure 1 Shown is an embodiment of the heating furnace of the present invention, which includes a furnace wall 1, a furnace hearth 8, a furnace door 7, a straight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com