Method for preparing nanometer ferroferric oxide microballoons with particle diameter adjustable by microwave

A technology of ferroferric oxide and particle size, which is applied in the field of preparation in the field of nanotechnology, and can solve problems such as difficult promotion, restrictions, and needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Weigh 0.3 g of ferric chloride (FeCl 3 ·6H 2 O) be dissolved in 10 ml of ethylene glycol, add 0.8 gram of sodium acetate and 0.1 gram of polyethylene glycol (molecular weight 4000), mix and stir for 20 minutes to obtain a precursor liquid for preparing ferric oxide.

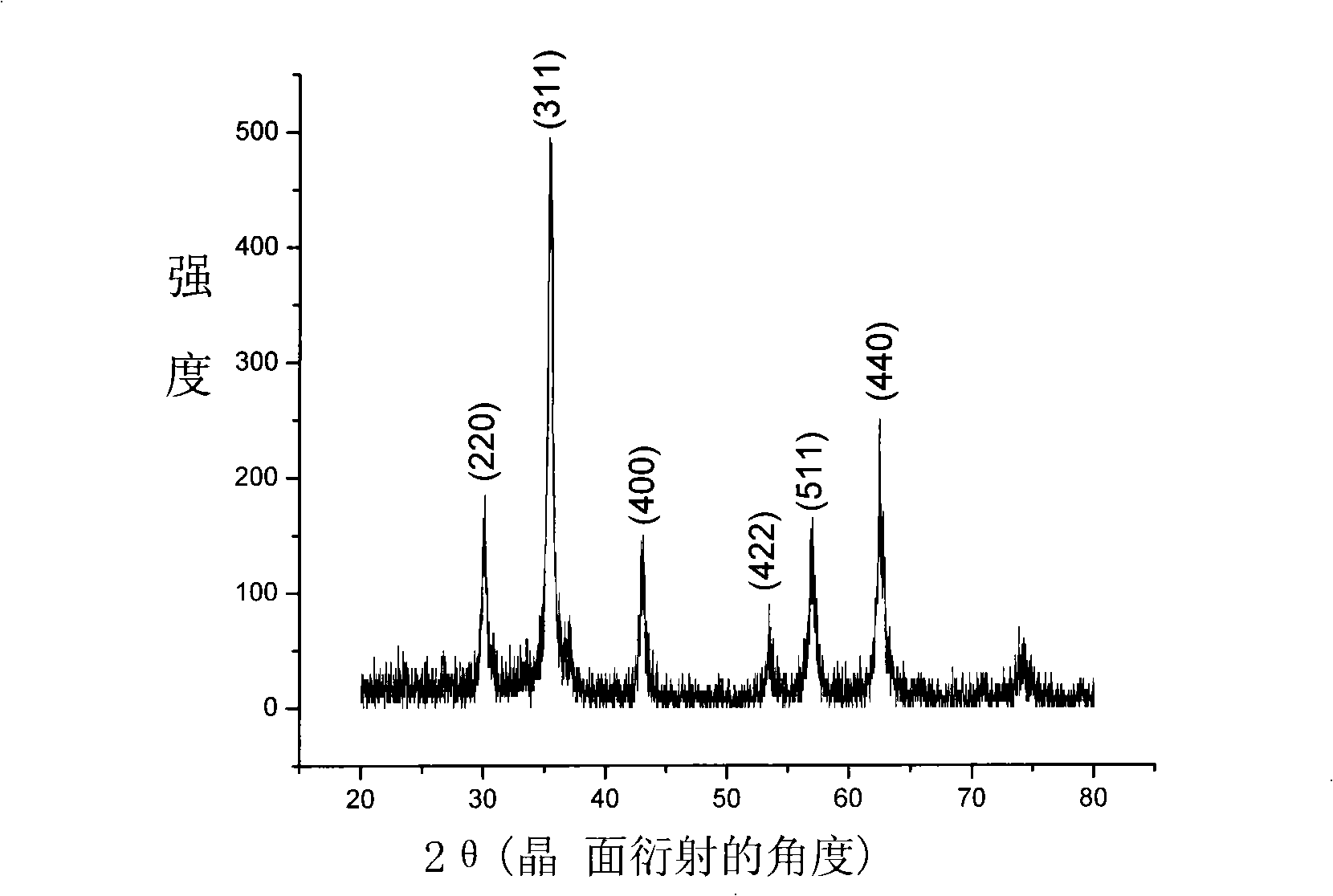

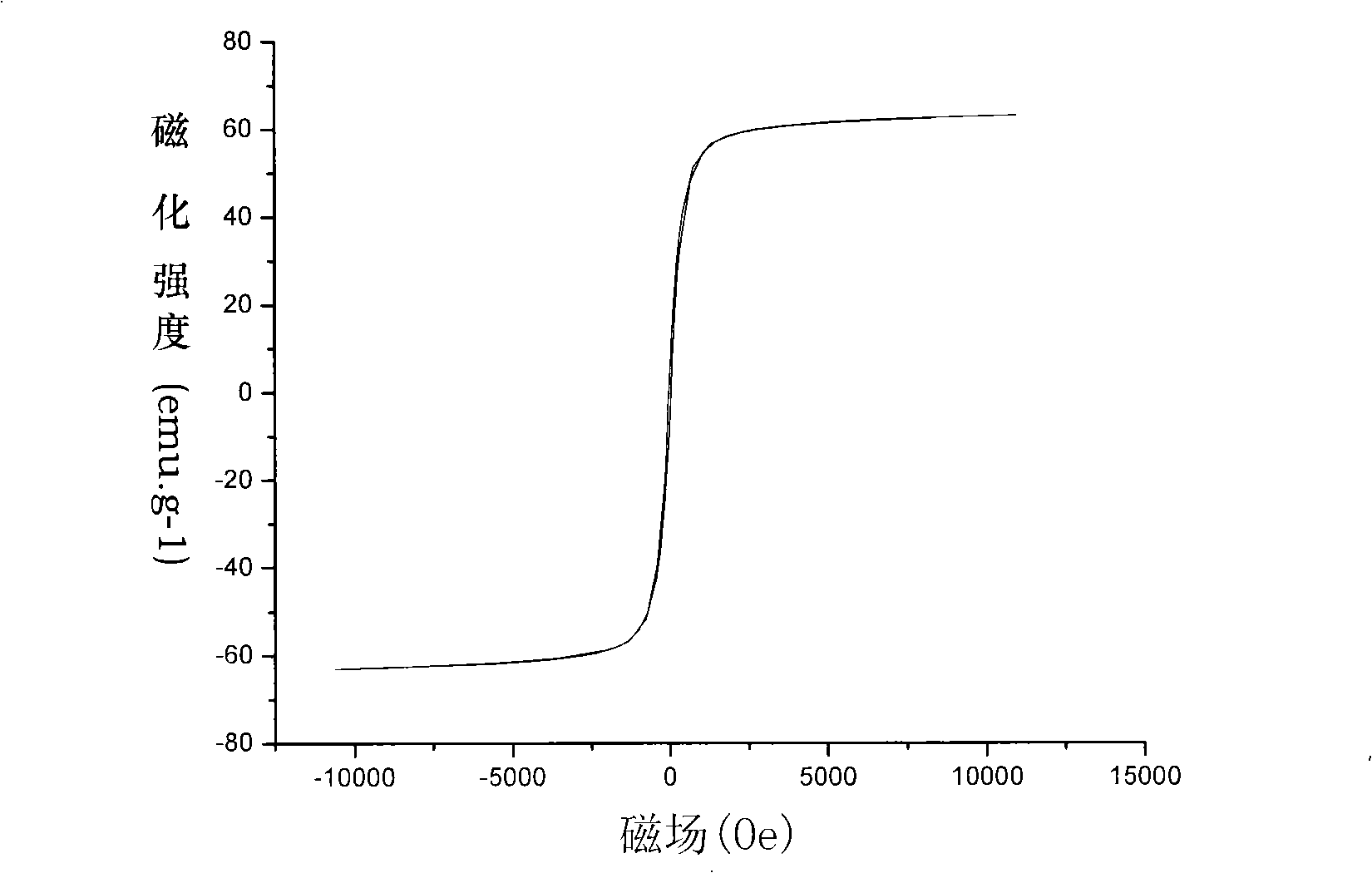

[0021] Put the obtained precursor liquid into a glassware specially used for microwave reaction to carry out microwave reaction. The conditions of microwave radiation are as follows: microwave power 15W; temperature 200 degrees; pressure 20PSI; time 5 hours. After microwave irradiation, ferric oxide nanoparticles are prepared, the particle size is 25nm, and the saturation magnetization is 63.1emu / g, and the ferric oxide nanoparticles can be dispersed in water and ethanol.

Embodiment 2

[0023] Weigh 0.3 g of ferric chloride (FeCl 3 ·6H 2 O) be dissolved in 10 milliliters of 1,3-propanediol, add 0.8 gram of sodium acetate and 0.2 gram of polyethylene glycol (molecular weight 8000), mix and stir for 20 minutes to obtain a precursor liquid for preparing ferric oxide.

[0024] Put the obtained precursor liquid into a glassware specially used for microwave reaction to carry out microwave reaction. The conditions of microwave radiation are as follows: microwave power 50W; temperature 200 degrees; pressure 30PSI; time 30 minutes. Ferric oxide nanoparticles were prepared after microwave irradiation, the particle diameter was 40nm, and the saturation magnetization was 69.6emu / g, and the prepared iron ferric oxide nanoparticles could be dispersed in water and ethanol.

Embodiment 3

[0026] Weigh 0.3 g of ferric chloride (FeCl 3 ·6H 2 O) be dissolved in 10 milliliters of glycerol, add 0.5 gram of sodium acetate and 0.3 gram of polyethylene glycol (molecular weight 20000), mix and stir for 20 minutes to obtain a precursor liquid for preparing ferric oxide.

[0027] Put the obtained precursor liquid into a glassware specially used for microwave reaction to carry out microwave reaction. The conditions of microwave radiation are as follows: microwave power 150W; temperature 250 degrees; pressure 40PSI; time 1 minute. The iron nanoparticles have a particle diameter of 80nm and a saturation magnetization of 77.6emu / g, and the prepared iron ferric oxide nanoparticles can be dispersed in water and ethanol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com