Processing process for fermentation waste liquid of lysine

A lysine fermentation and waste liquid technology, which is applied in water/sewage treatment, aerobic process treatment, natural water body treatment, etc., can solve the problem of high power consumption of HCR process, no benefit, and insufficient treatment of lysine fermentation waste liquid Ideal and other issues, to achieve obvious environmental and social benefits, expand production scale, and reduce pollutant emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited in any way.

[0057] Treatment and comprehensive utilization of embodiment lysine fermentation waste liquid

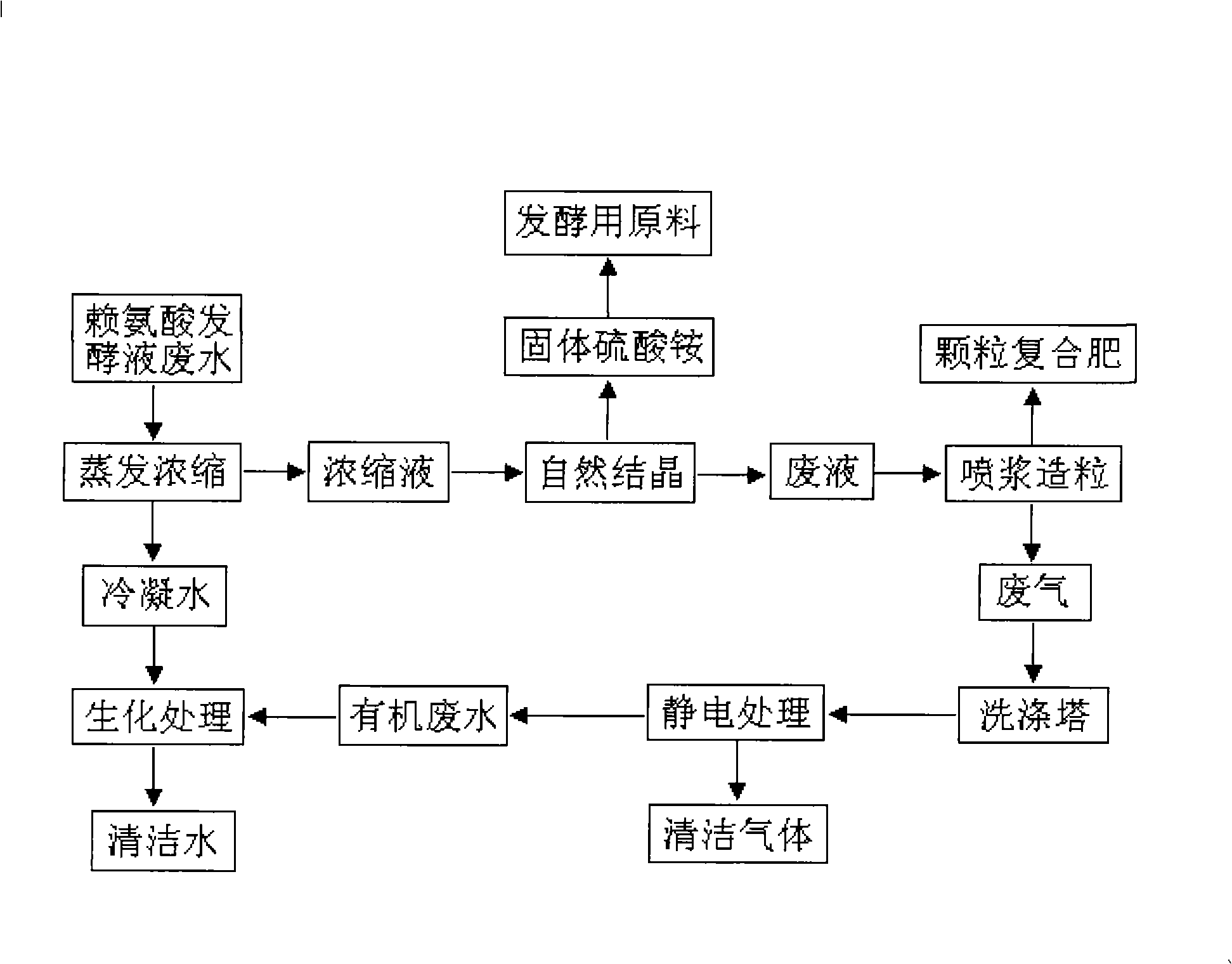

[0058] In this embodiment, the lysine fermentation waste liquid is treated according to the method of the present invention, and the steps and process are as attached figure 1 shown.

[0059] Treatment of Lysine Wastewater

[0060] 1. Concentration of lysine wastewater: 300m 3 The lysine fermentation waste liquid is evaporated by four effects, and the evaporation conditions of each effect are: first effect: 0.04Mpa, 99~102℃; second effect: 0.06Mpa, 88~92℃; third effect: 0.08Mpa, 75~78℃ ;Four effects: 0.9Mpa, 60~62℃. The solid content of the evaporated material is about 60%, and the concentrated solution is 40m 3 , the condensed water is 260m 3 , the condensed water enters the aerobic treatment system for c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com