Method for preparing carboxylic acid-modified vinyl chloride-vinyl acetate copolymer resins

A technology of vinyl acetate copolymer resin and vinyl acetate, which is applied in the field of preparation of carboxylic acid modified vinyl chloride-vinyl acetate copolymer resin, can solve the problems of difficult copolymerization reaction and difficult full contact, etc., and achieves the improvement of compatibility and Adhesive force, elimination of peeling, effect of clean production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

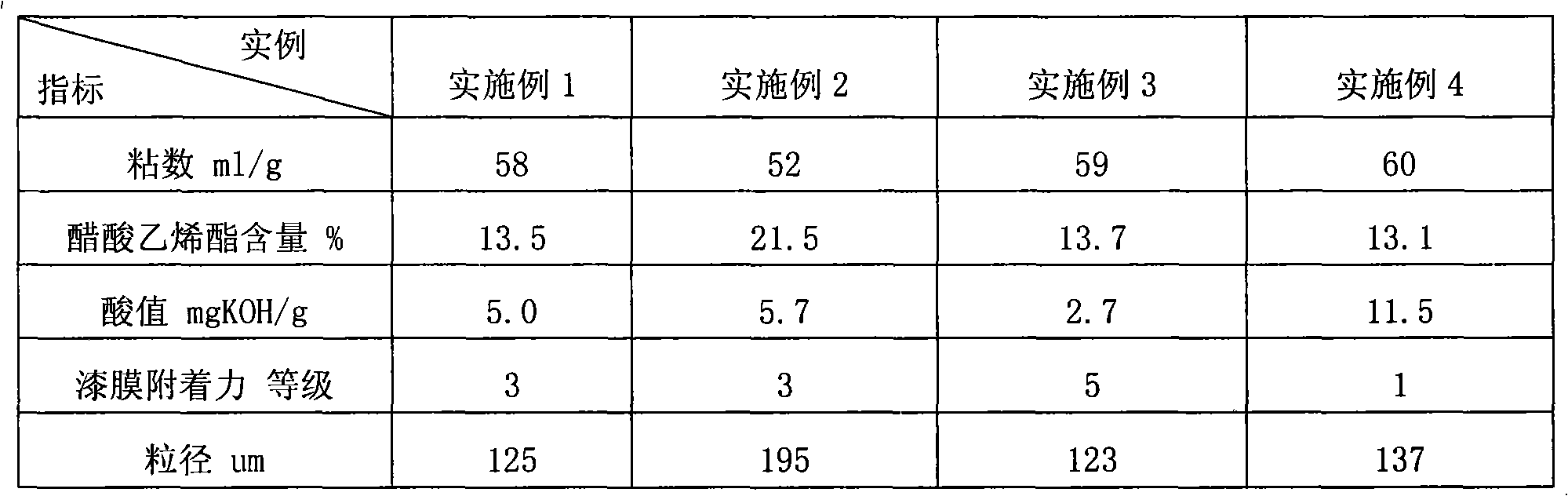

Embodiment 1

[0037] Step 1: Weigh 25g of fumaric acid and 50g of ethanol into a 250ml three-neck flask, heat up to 65°C, stir and react for 2.0hr to obtain a fumaric esterification reaction product, and put it into a 10L high-pressure polymerization kettle;

[0038] The second step: add 300g vinyl acetate monomer, 3500g water, 2.0g polyvinyl alcohol with alcoholysis degree of 75%, 3.0g hydroxypropyl methylcellulose, weight concentration of 20% polyvinyl alcohol in a 10L polymerization kettle. 0.20g mercaptoethanol, 0.50g ammonium bicarbonate and 1200g vinyl chloride monomer, initiator peroxide di-(3,5,5-trimethylhexyl) 0.80g and 0.40g neodecanoate tert-butyl peroxide, The temperature was raised to 65°C, and the polymerization reaction was carried out at a pressure of 0.88Mpa;

[0039] Step 3: Polymerize for 1.5hr. At this time, the conversion rate of vinyl chloride is 20%. Add 0.50g of mercaptoethanol aqueous solution with a weight concentration of 0.15%, and finish adding within 2 hours. ...

Embodiment 2

[0041] The first step is the same as in Example 1; in the second step, 500g of vinyl acetate monomer and 1250g of vinyl chloride monomer are added simultaneously in a 10L polymerization kettle, and other processes are the same as in Example 1, and the pressure is 0.76Mpa; in the third step, polymerization is 1.5hr , continuously add 250g vinyl chloride monomer, keep the pressure constant until the monomer is added, other processes are the same as in Example 1.

Embodiment 3

[0043] Step 1: Weigh 10g of fumaric acid and 30g of ethanol into a 100ml three-neck flask, heat up to 65°C, stir and react for 2.0hr to obtain a fumaric esterification reaction product, and put it into a 10L high-pressure polymerization kettle;

[0044] The second step and the third step process are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com