Hydrothermal preparation method for aluminum oxide whiskers at low temperature

An alumina whisker and hydrothermal technology, applied in chemical instruments and methods, single crystal growth, crystal growth, etc., can solve problems such as high temperature and pressure, high equipment requirements, unfavorable operation, etc., to improve mechanical properties and purity High, high-conversion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] ①Batching process: Dissolve 7.5g of aluminum nitrate in 20ml of distilled water to prepare a solution with a concentration of 1mol / L, add 3.6g of urea to the above-mentioned aluminum nitrate solution, stir at room temperature for half an hour to obtain a transparent and clear sol.

[0019] ② Hydrothermal process: put the prepared transparent and clear sol in a reaction kettle, and react at 120°C for 6 hours to obtain a white precipitate.

[0020] ③ Washing process: the obtained white precipitate is filtered and washed with distilled water, and filtered to obtain a uniform alumina whisker precursor.

[0021] ④ Roasting process: put the precursor in a muffle furnace and bake at 1200°C for 2 hours to obtain alumina whiskers.

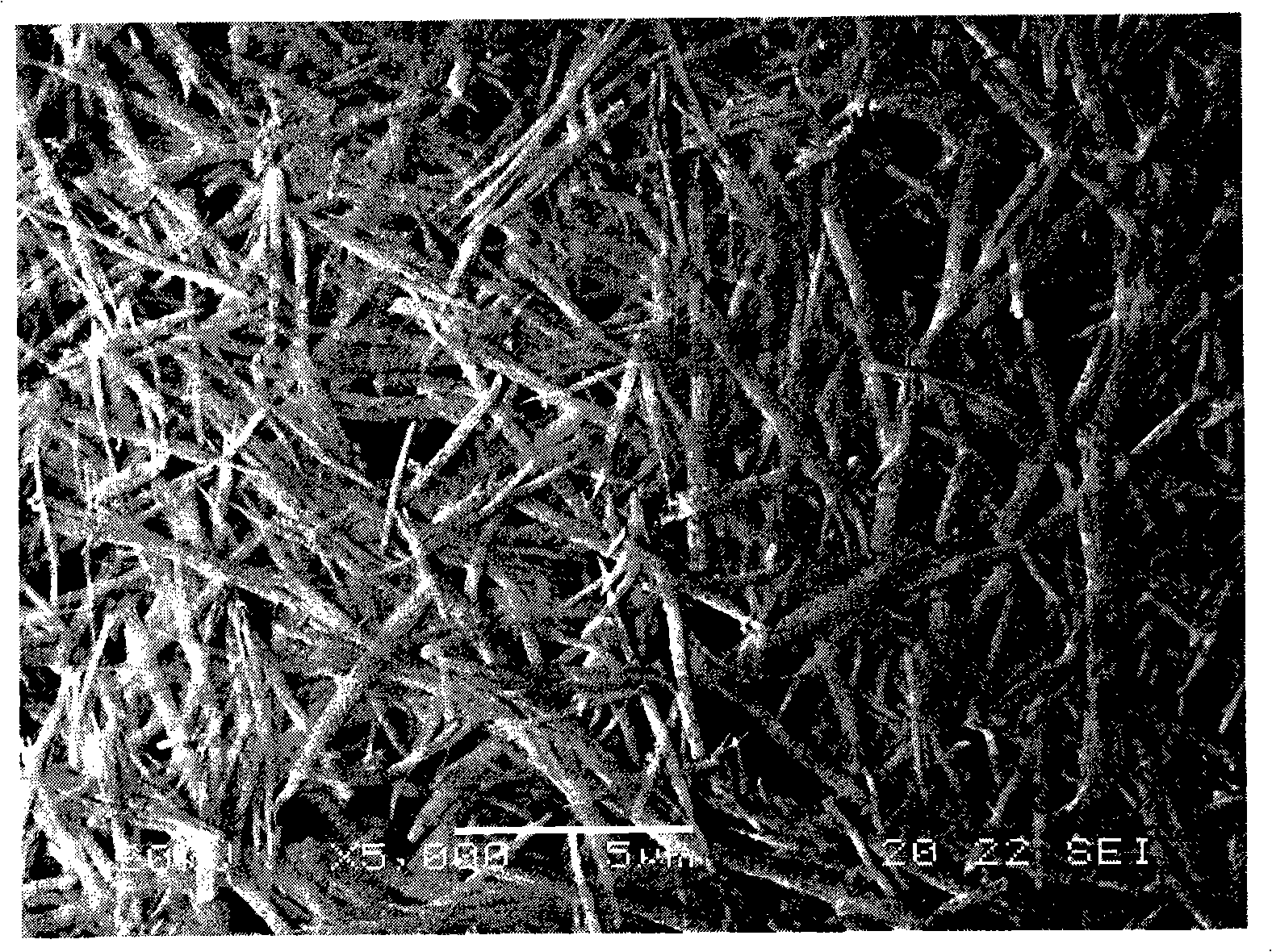

[0022] The alumina whisker product was identified as a pure phase by X-ray diffraction. The whisker has an average diameter of 0.5 μm and a length of 5-10 μm; the yield is above 95%. The SEM scanning picture of alumina whisker products is shown in ...

Embodiment 2

[0024] ①Batching process: Dissolve 7.5g of aluminum nitrate in 20ml of distilled water to prepare a solution with a concentration of 1mol / L, add 6.0g of urea to the above-mentioned aluminum nitrate solution, stir at room temperature for half an hour to obtain a transparent and clear sol.

[0025] ② Hydrothermal process: put the prepared transparent and clear sol in a reaction kettle, and react at 120°C for 6 hours to obtain a white precipitate.

[0026] ③ Washing process: the obtained white precipitate is filtered and washed with distilled water, and filtered to obtain a uniform alumina whisker precursor.

[0027] ④ Roasting process: put the precursor in a muffle furnace and bake at 1200°C for 2 hours to obtain alumina whiskers.

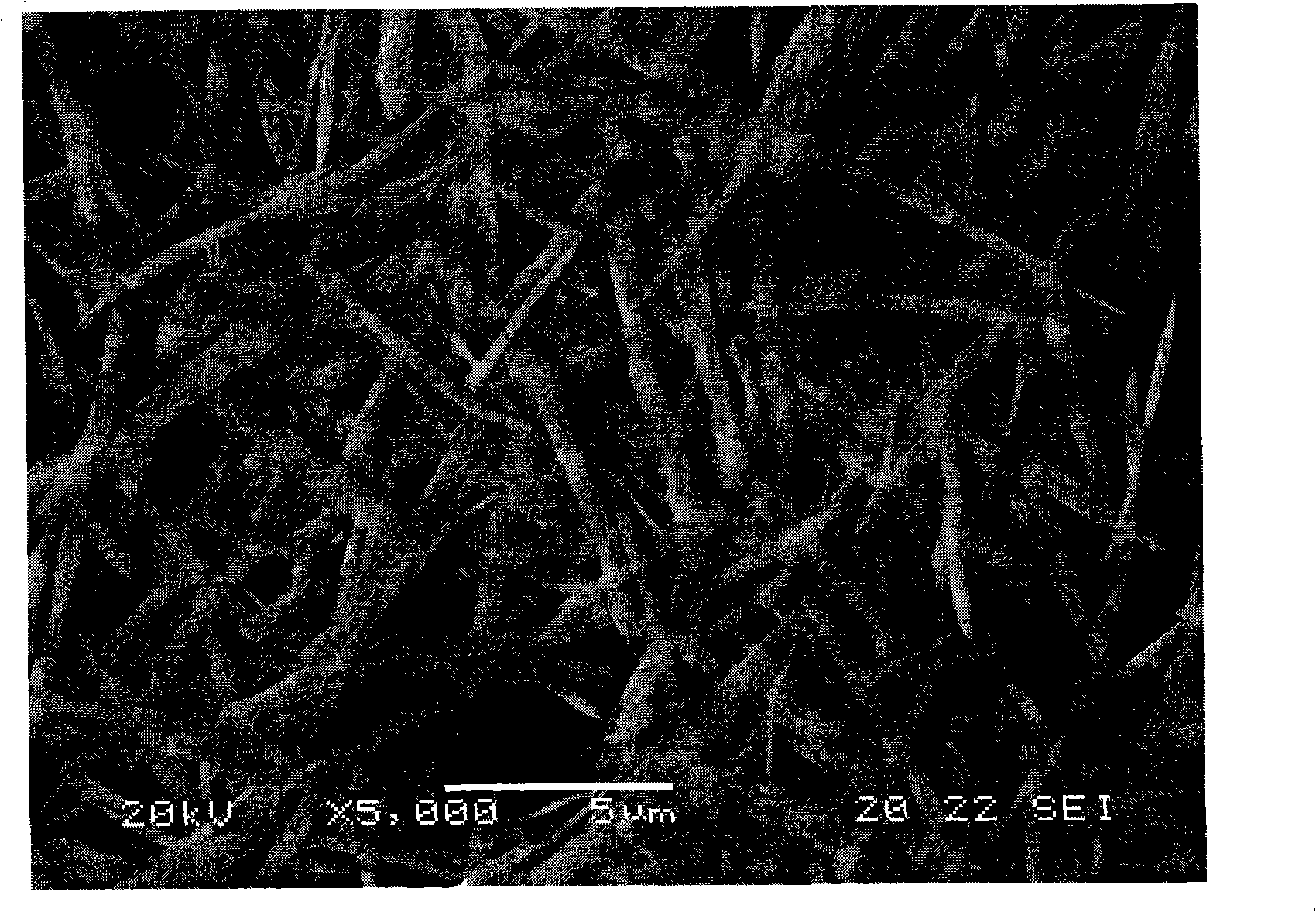

[0028] The alumina whisker product was identified as a pure phase by X-ray diffraction. The whisker has an average diameter of 0.5 μm and a length of 5-10 μm; the yield is over 95%. The SEM scanning picture of alumina whisker products is shown in ...

Embodiment 3

[0030] ①Batching process: Dissolve 11.25g of aluminum nitrate in 20ml of distilled water to prepare a solution with a concentration of 1.5mol / L, add 16.2g of urea to the above-mentioned aluminum nitrate solution, and stir at room temperature for half an hour to obtain a transparent and clear sol.

[0031] ② Hydrothermal process: the prepared transparent and clear sol was placed in a reaction kettle, and reacted at 110°C for 8 hours to obtain a white precipitate.

[0032] ③ Washing process: the obtained white precipitate is filtered and washed with distilled water, and filtered to obtain a uniform alumina whisker precursor.

[0033] ④ Roasting process: put the precursor in a muffle furnace and bake at 1200°C for 2 hours to obtain alumina whiskers.

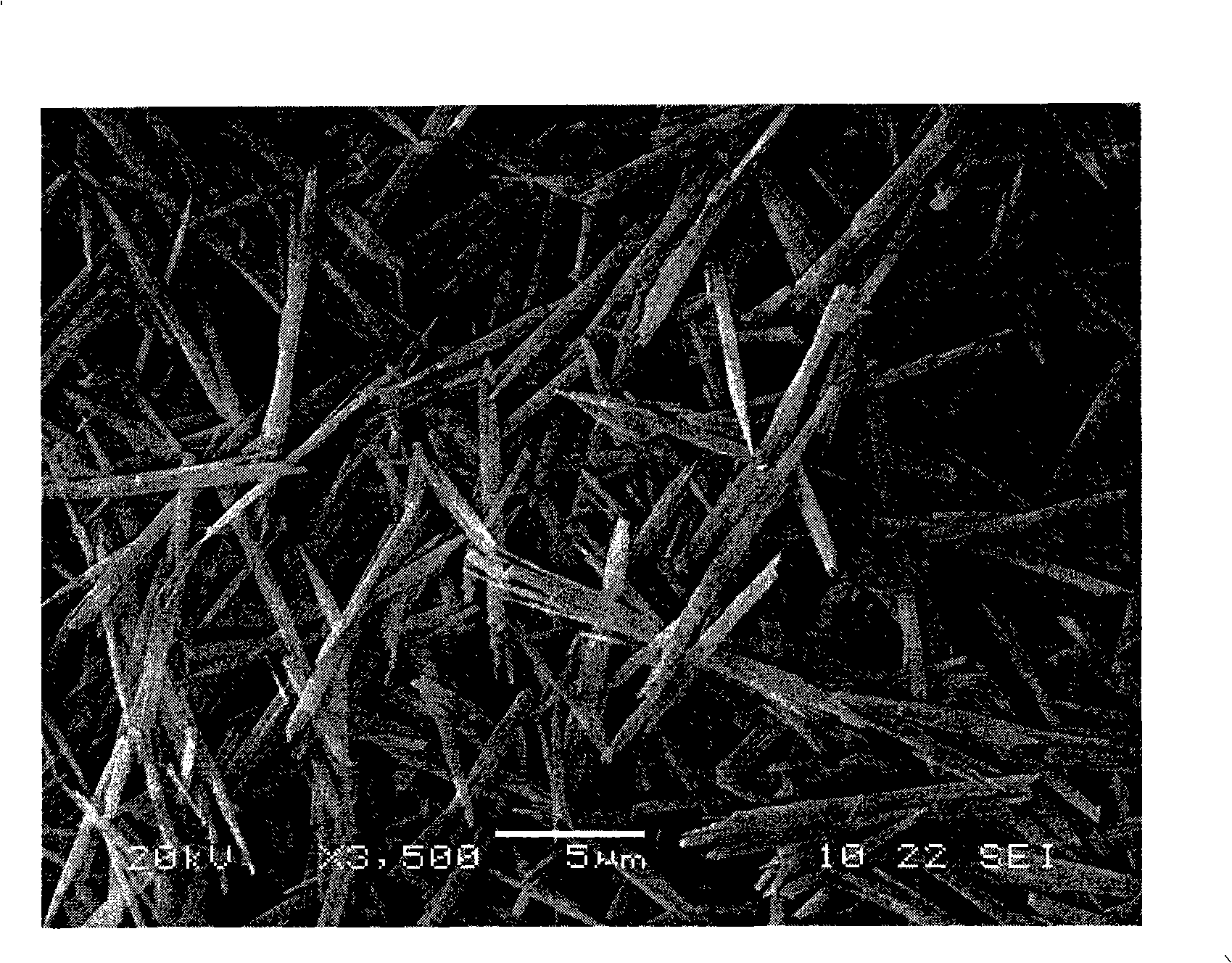

[0034] The alumina whisker product was identified as a pure phase by X-ray diffraction. The whiskers have an average diameter of 0.5 μm and a length of 5-10 μm; the yield is over 95%. The SEM scanning picture of alumina whisker pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com