Method for checking semiconductor substrate crystal quality by linear polarized light

A technology of linearly polarized light and crystal quality, applied in the direction of polarization influence characteristics, optical test flaws/defects, etc., can solve the problems of long preparation period, material destruction, expensive instruments, etc., to achieve low instrument cost and operating cost, improve Yield, material and money savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

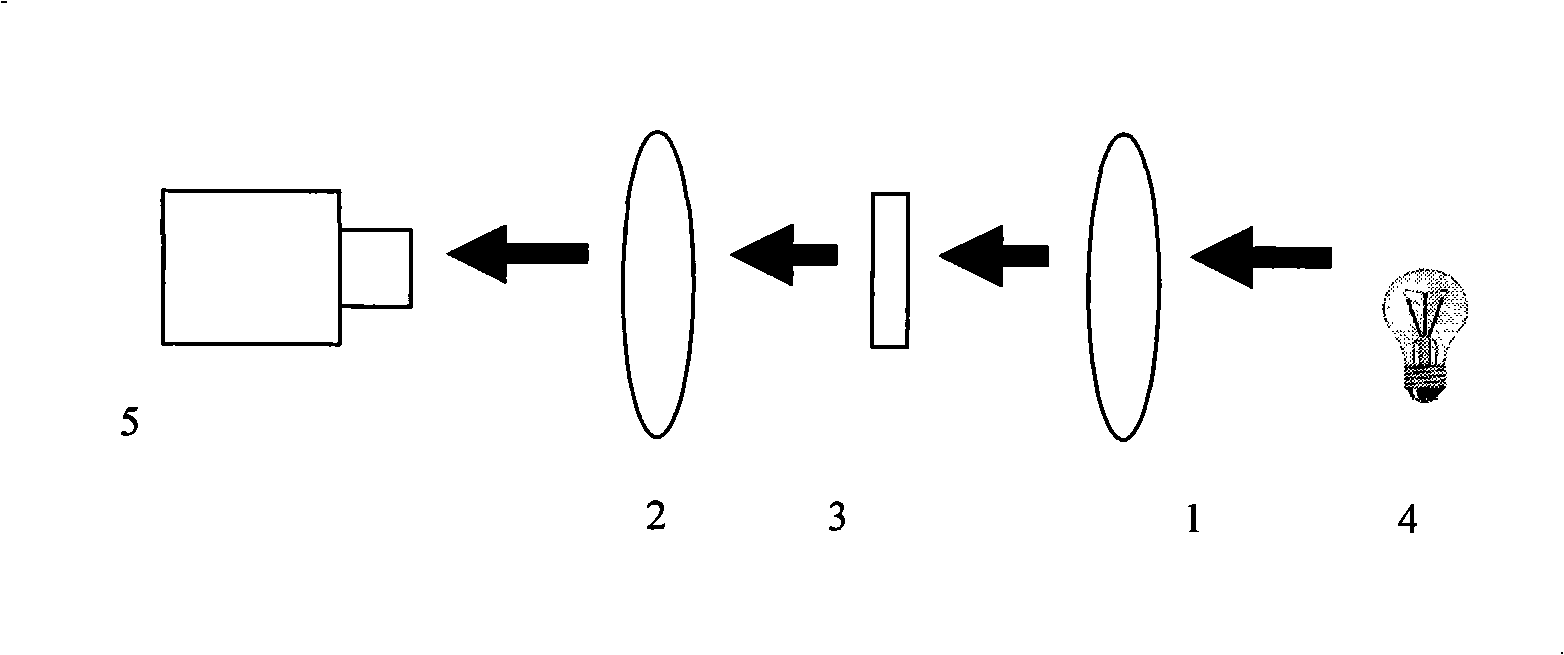

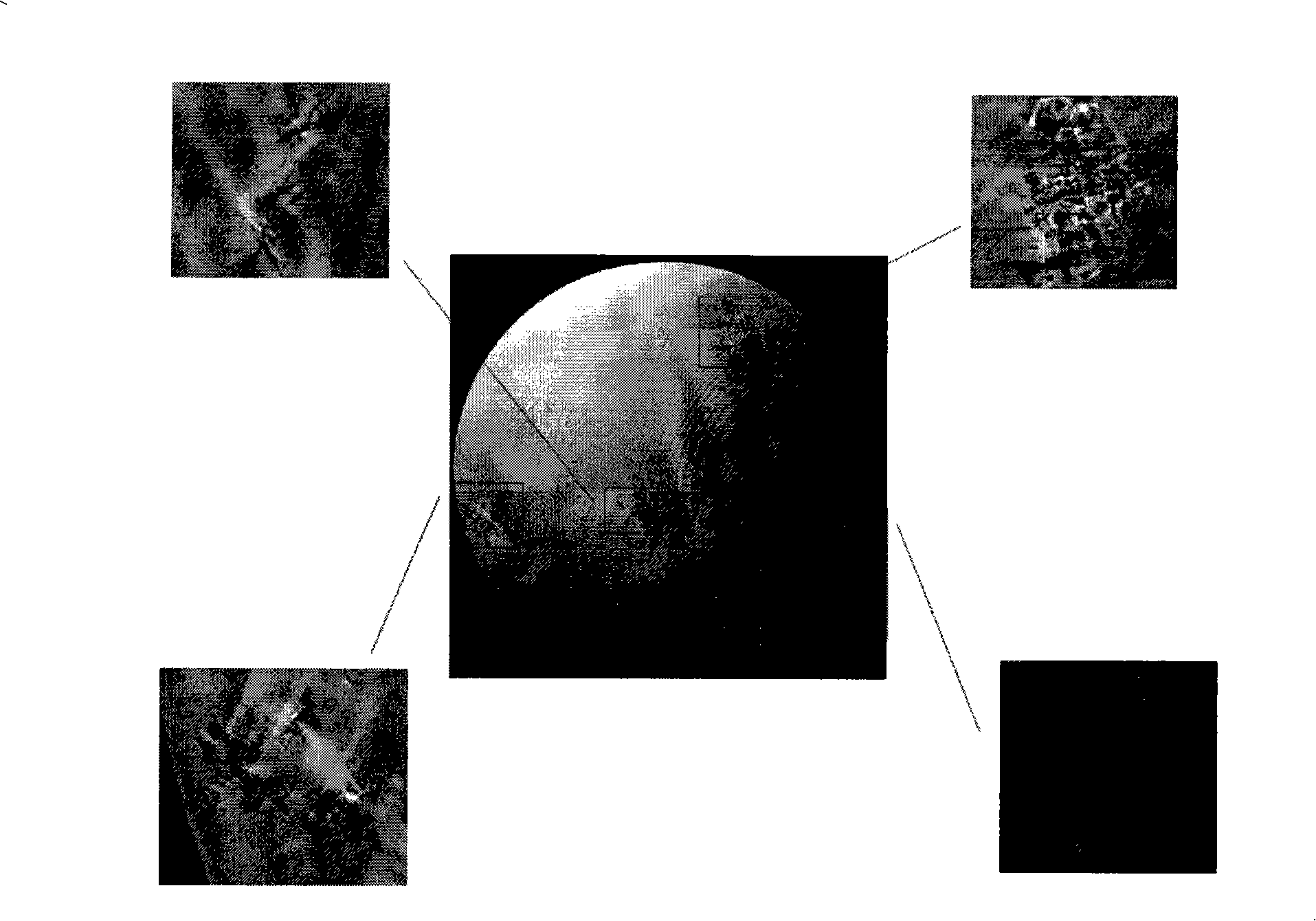

[0015] To further illustrate the content of the present invention, the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings. Among them: see figure 1 As shown, the working process of the method for inspecting the quality of semiconductor substrate crystals using linearly polarized light is:

[0016] 1) A light source 4 is used to generate light of uniform intensity, which light must be able to partially pass through the crystal material 3;

[0017] 2) The light is irradiated vertically on the linear polarizer 1 to generate linearly polarized light;

[0018] 3) The linearly polarized light is irradiated on the 2-inch whole SiC material, and a part of the light is transmitted through the material;

[0019] 4) The transmitted light passes through the linear polarizer 2, and its polarization direction is perpendicular to the linear polarizer 1;

[0020] Finally, it is received and displayed by the optical imaging syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com