Method for preparing carbon-copper fibre integral fabric/carbon-copper based composite material

A copper-based composite material and copper fiber technology, applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve the problems of large fluctuations in product performance, unsuitable for mass production, and high operating costs, and achieve easy implementation. Industrialization, good electrical conductivity, the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

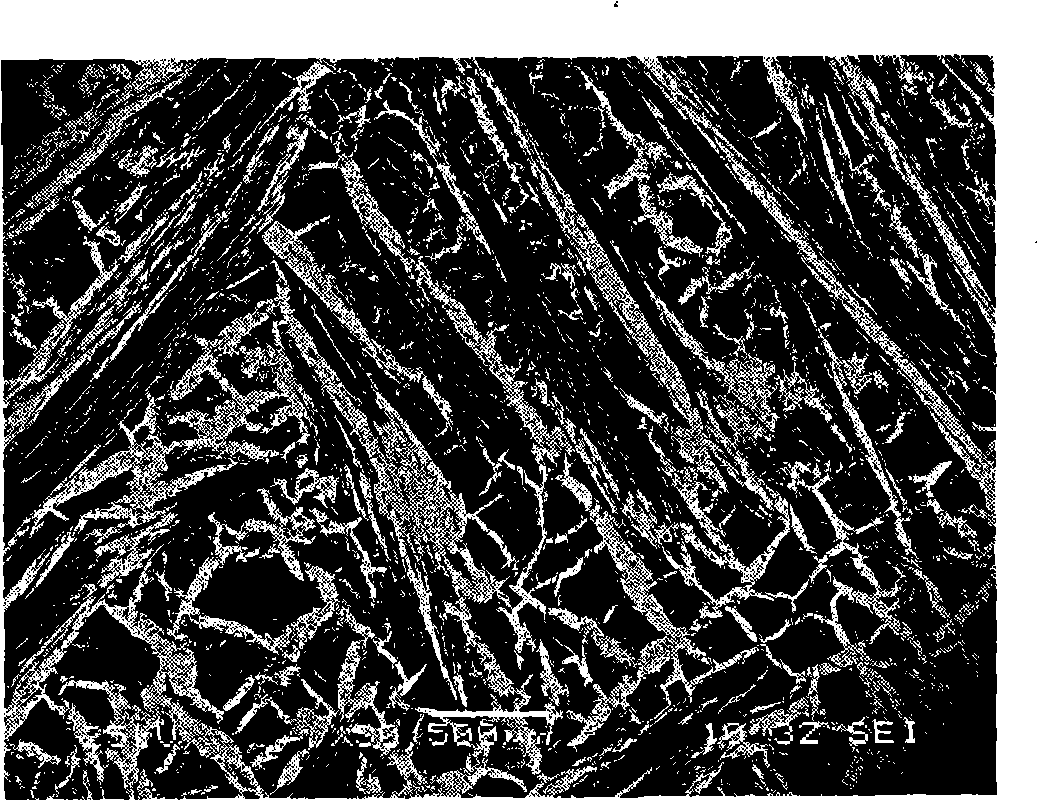

[0016] Use 3K carbon fiber and 1 Φ0.1mm copper wire to wind and softly weave into a two-dimensional network. The 10μm natural flake graphite powder, the amount of graphite powder sprinkled is about 100g per square meter, and the chemical vapor infiltration is carried out for 80h; the infiltration agent containing 5wt% Ti is prepared; the composite green body is embedded with the prepared infiltration agent. Under vacuum conditions, the temperature was kept at 1100°C for 15 minutes to prepare a carbon-copper fiber integrated fabric / carbon-copper matrix composite material numbered A. Its SEM photos are attached figure 1 .

Embodiment 2

[0018] A combination of 12K carbon fiber and Φ0.1mm copper wire is used to wind and softly weave into a two-dimensional network. The 10μm natural flake graphite powder, the amount of graphite powder sprinkled is about 150g per square meter, and the chemical vapor infiltration is carried out for 100h; the infiltration agent containing 7wt%Ti is prepared; the composite green body is embedded with the prepared infiltration agent, and the Under vacuum conditions, heat preservation at 1300°C for 15 minutes, and a carbon-copper fiber integrated fabric / carbon-copper matrix composite material numbered B was prepared.

Embodiment 3

[0020] Use 6K carbon fiber and 1 Φ0.1mm copper wire to wind and softly weave into a two-dimensional network. The 10μm natural flake graphite powder, the amount of graphite powder sprinkled is about 200g per square meter, and the chemical vapor infiltration is carried out for 120h; the infiltration agent containing 10wt% Ti is prepared; the composite green body is embedded with the prepared infiltration agent, and the Under vacuum conditions, the temperature was kept at 1500°C for 5 minutes to prepare a carbon-copper fiber integrated fabric / carbon-copper matrix composite material numbered C.

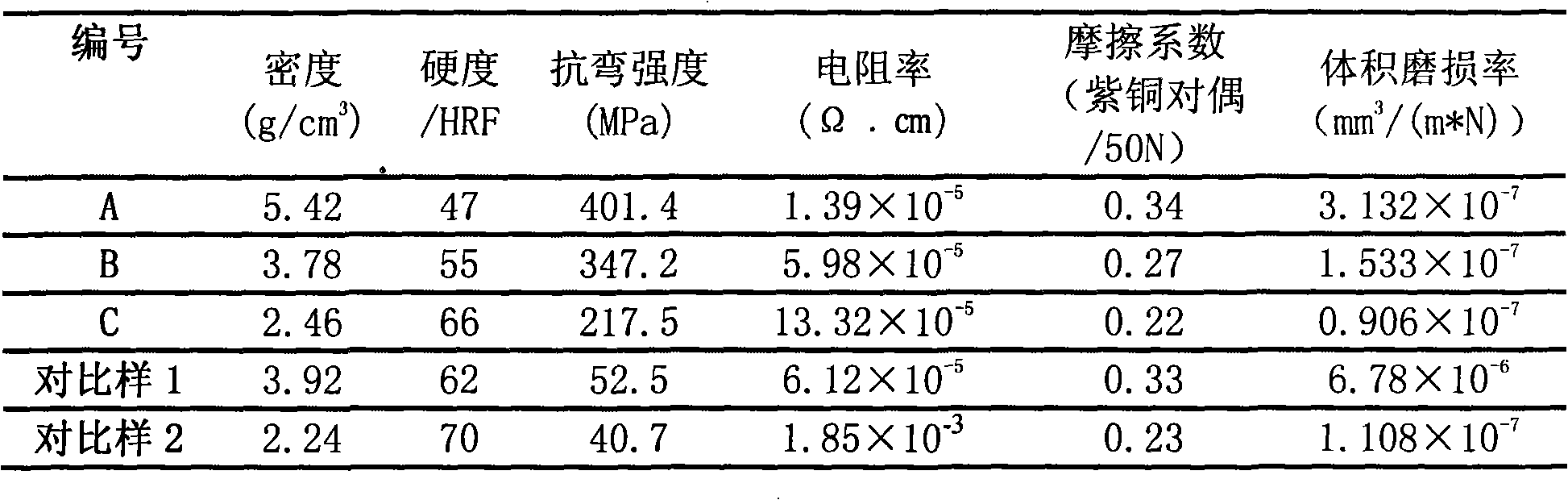

[0021] Table 1 shows the main performance indicators of the three carbon-copper fiber integral fabrics / carbon-copper matrix composite materials A, B, and C obtained in implementations 1 to 3. In addition, the comparative sample 1 is a J204 copper graphite brush, and the comparative sample 2 is a sliding plate material imported from Germany. It can be seen from Table 1 that, compared with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com