Method for continuous preparation of sulfur with high heat-stability and insolubility

A technology with high thermal stability and sulfur, which is applied in the preparation/purification of sulfur, can solve the problems of explosion, poor continuity, and easy combustion of insoluble sulfur, and achieve uniform product quality and avoid flammable and explosive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

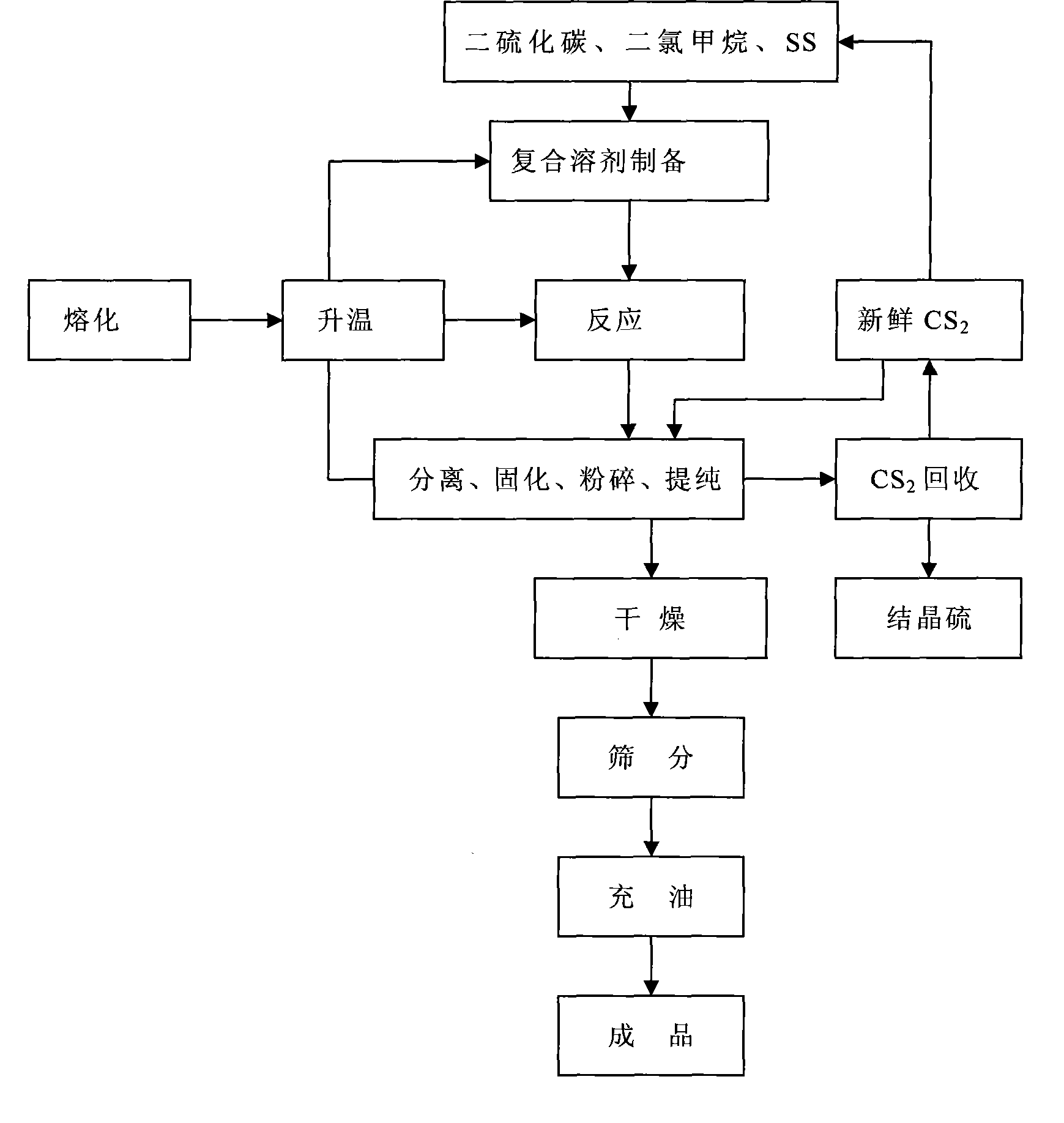

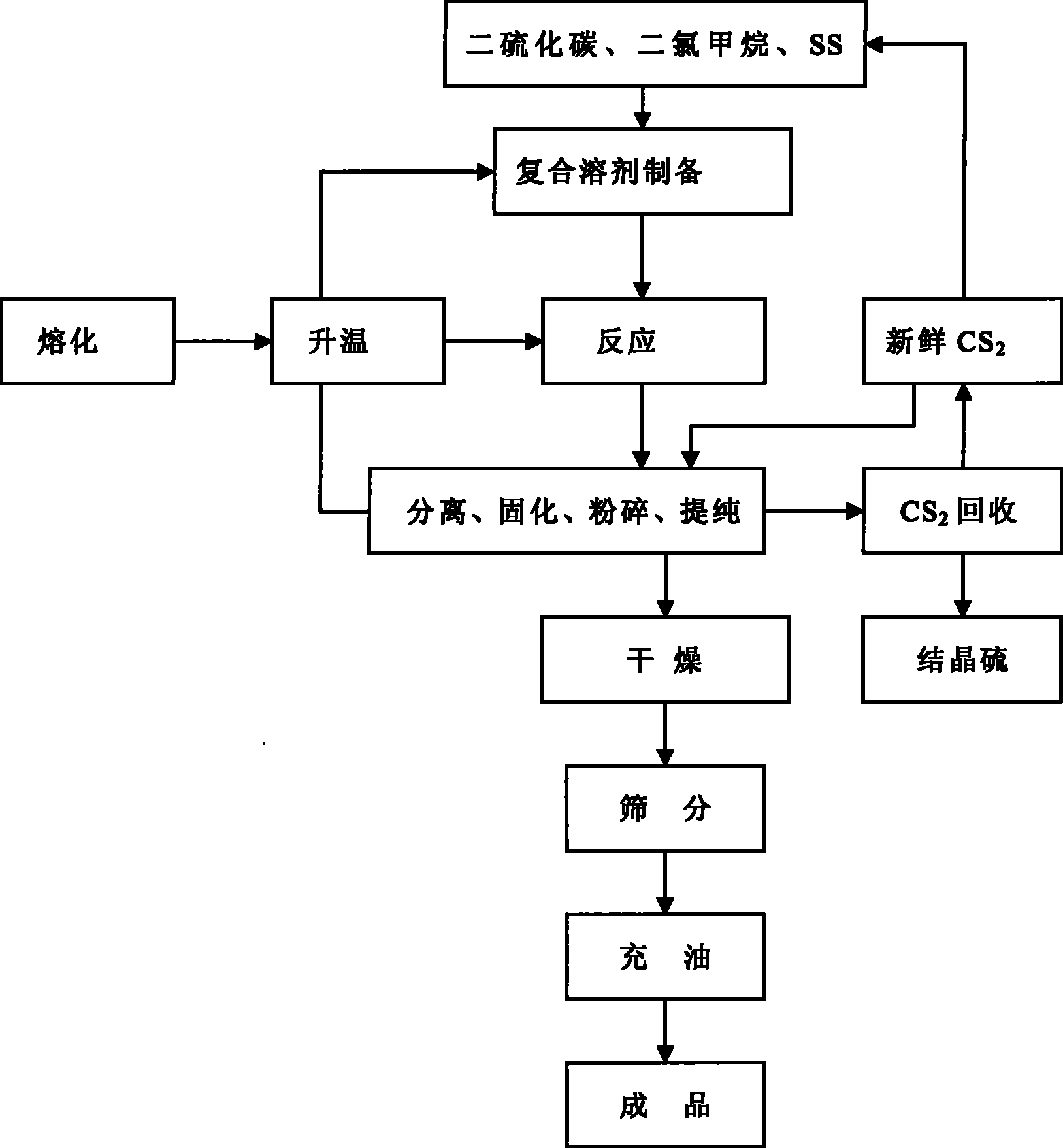

Image

Examples

Embodiment 1

[0025] The method for continuously producing high thermal stability insoluble sulfur of the present invention comprises the following steps:

[0026] a. Raw material sulfur is melted and heated up: the raw material sulfur, namely industrial sulfur, is heated in a sulfur melting tank for 4 hours with 0.3-0.4 Mpa water vapor, pumped into a sulfur heating tank, and heated to 600°C;

[0027] b. Composite solvent preparation: Add carbon disulfide, methylene chloride, and SS additives into the composite solvent circulation tank to form a composite solvent. The weight ratio is carbon disulfide: methylene chloride: SS=87:12:1, and the SS additive uses α- methyl styrene;

[0028] c. Reaction: In a reaction tank with a stirring device, first add the composite solvent cooled to 12°C to 70% of the volume, and directly pass high-temperature gaseous sulfur at 600°C into the composite solvent for contact reaction to generate insoluble sulfur. Continuously feed the composite solvent at 12°C ...

Embodiment 2

[0035] The method for continuously producing high thermal stability insoluble sulfur of the present invention comprises the following steps:

[0036] a. Raw material sulfur is melted and heated up: the raw material sulfur, namely industrial sulfur, is heated in a sulfur melting tank for 3 hours with 0.3-0.4 Mpa steam to melt, pumped into the sulfur heating tank through a pump, and heated to 550°C;

[0037] b. Composite solvent preparation: Add carbon disulfide, methylene chloride, and SS additives into the composite solvent circulation tank to form a composite solvent. The weight ratio is carbon disulfide: dichloromethane: SS = 78:5:0.01, and the SS additive uses isopentyl Diene;

[0038] c. Reaction: In a reaction tank with a stirring device, first add the composite solvent cooled to 5°C to 70% of the volume, and directly pass high-temperature gaseous sulfur at 550°C into the composite solvent for contact reaction to generate insoluble sulfur. Continuously feed the composite...

Embodiment 3

[0045] The method for continuously producing high thermal stability insoluble sulfur of the present invention comprises the following steps:

[0046] a. Raw material sulfur is melted and heated up: raw material sulfur, namely industrial sulfur, is heated in a sulfur melting tank for 5 hours with 0.3-0.4Mpa water vapor, pumped into a sulfur heating tank, and heated to 650°C;

[0047] b. Composite solvent preparation: Add carbon disulfide, methylene chloride, and SS additives into the composite solvent circulation tank to form a composite solvent. The weight ratio is carbon disulfide: dichloromethane: SS=95:20:2, and the SS additive is 1- Vinyl-3-cyclohexene;

[0048] c. Reaction: In a reaction tank with a stirring device, first add the composite solvent cooled to 20°C to 70% of the volume, and directly pass high-temperature gaseous sulfur at 650°C into the composite solvent for contact reaction to generate insoluble sulfur. Continuously feed the composite solvent at 20°C and sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com