Method for continuous preparation of sulfur with high heat-stability and insolubility

A high thermal stability, sulfur technology, applied in the preparation/purification of sulfur, etc., can solve the problems of weak continuity, explosion, unstable product quality, etc., and achieve the effect of avoiding flammability and explosion, and achieving uniform product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

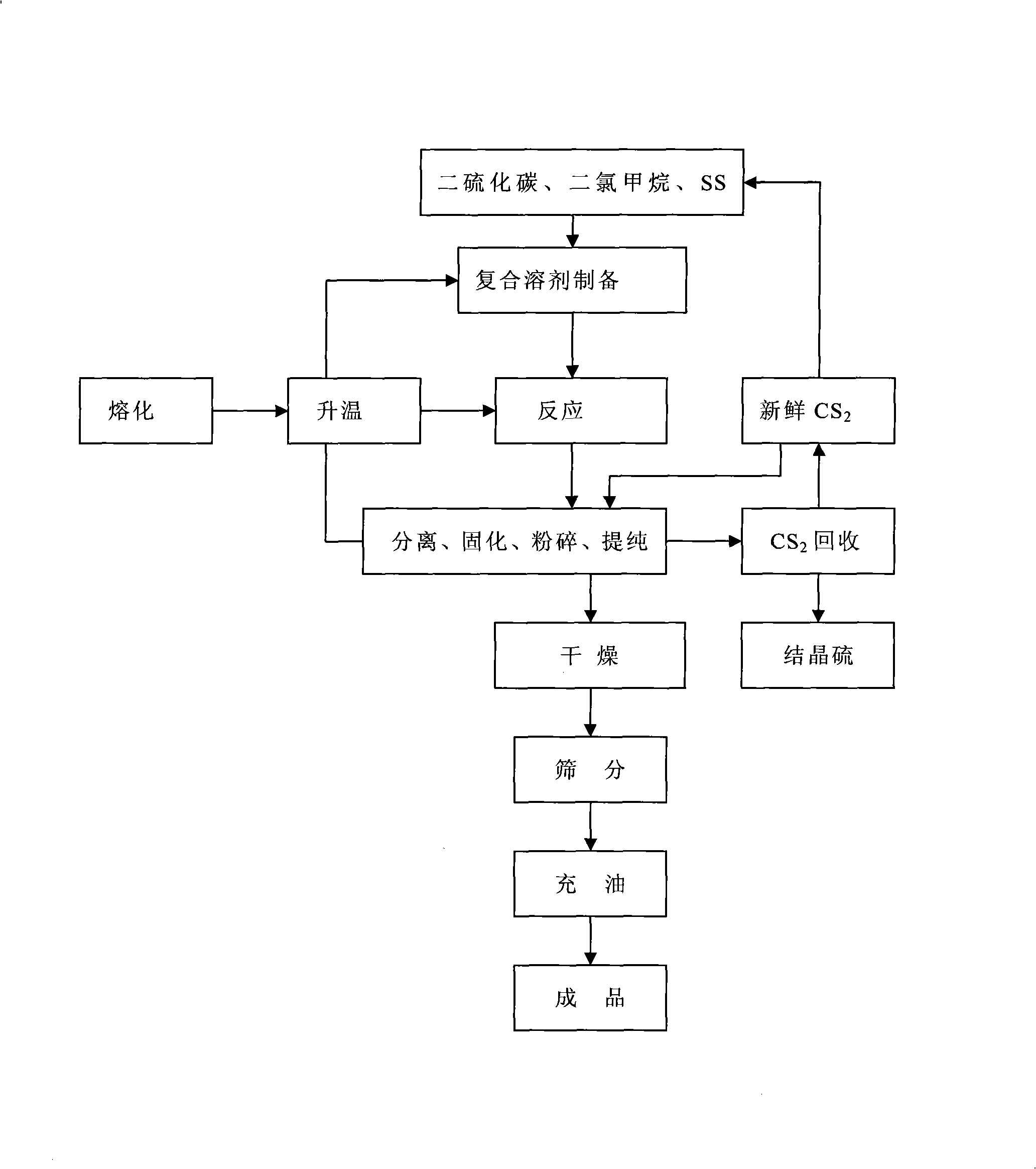

[0025] The method for continuously producing high thermal stability insoluble sulfur of the present invention comprises the following steps:

[0026] a. Raw material sulfur is melted and heated up: the raw material sulfur, namely industrial sulfur, is heated in a sulfur melting tank for 4 hours with 0.3-0.4 Mpa water vapor, pumped into a sulfur heating tank, and heated to 600°C;

[0027] B, composite solvent preparation: add carbon disulfide, methylene chloride, and SS auxiliary agent to form composite solvent in the composite solvent circulation tank, the weight ratio is carbon disulfide: methylene chloride: SS=87: 12: 1, SS auxiliary agent adopts α- methyl styrene;

[0028] c. Reaction: In a reaction tank with a stirring device, first add the composite solvent cooled to 12°C to 70% of the volume, and directly pass high-temperature gaseous sulfur at 600°C into the composite solvent for contact reaction to generate insoluble sulfur. Continuously feed the composite solvent at ...

Embodiment 2

[0035] The method for continuously producing high thermal stability insoluble sulfur of the present invention comprises the following steps:

[0036] a. Raw material sulfur is melted and heated up: the raw material sulfur, namely industrial sulfur, is heated in a sulfur melting tank for 3 hours with 0.3-0.4 Mpa steam to melt, pumped into the sulfur heating tank through a pump, and heated to 550°C;

[0037] B, composite solvent preparation: add carbon disulfide, methylene chloride, and SS auxiliary agent to form composite solvent in the composite solvent circulation tank, the weight ratio is carbon disulfide: methylene chloride: SS=78: 5: 0.01, SS auxiliary agent adopts isopentyl Diene;

[0038] c. Reaction: In a reaction tank with a stirring device, first add the composite solvent cooled to 5°C to 70% of the volume, and directly pass high-temperature gaseous sulfur at 550°C into the composite solvent for contact reaction to generate insoluble sulfur. Continuously feed the com...

Embodiment 3

[0045] The method for continuously producing high thermal stability insoluble sulfur of the present invention comprises the following steps:

[0046] a. Raw material sulfur is melted and heated up: raw material sulfur, namely industrial sulfur, is heated in a sulfur melting tank for 5 hours with 0.3-0.4Mpa water vapor, pumped into a sulfur heating tank, and heated to 650°C;

[0047] B, composite solvent preparation: add carbon disulfide, methylene dichloride, and SS auxiliary agent to form composite solvent in the composite solvent circulation tank, the weight ratio is carbon disulfide: methylene chloride: SS=95: 20: 2, SS auxiliary agent adopts 1- Vinyl-3-cyclohexene;

[0048] c. Reaction: In a reaction tank with a stirring device, first add the composite solvent cooled to 20°C to 70% of the volume, and directly pass high-temperature gaseous sulfur at 650°C into the composite solvent for contact reaction to generate insoluble sulfur. Continuously feed the composite solvent at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com