Metal polishing liquid and polishing method using it

A technology of abrasive liquid and metal, applied in the direction of polishing composition containing abrasive, grinding device, grinding machine tool, etc., can solve problems such as difficulties and achieve the effect of reducing abrasive particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4 and comparative example 1

[0061] (Examples 1-4 and Comparative Example 1: Polishing liquid 1 for metal)

[0062] The metal grinding liquid 1 that uses is to contain the organic acid (oxidized metal dissolving agent) below 1 mass %, the nitrogen-containing cyclic compound (metal anticorrosion agent) below 0.5 mass %, the water-soluble macromolecular ( additive), hydrogen peroxide (oxidizing agent) and water at 10% by mass or less. In addition, the primary particle diameter is within the range of ±10% of the average value described in Table 1, and the secondary particle diameter is within the range of ±15% of the average value described in Table 1, and the surface potentials described in Table 1 are different. Abrasive particles are added to the metal abrasive liquid 1 .

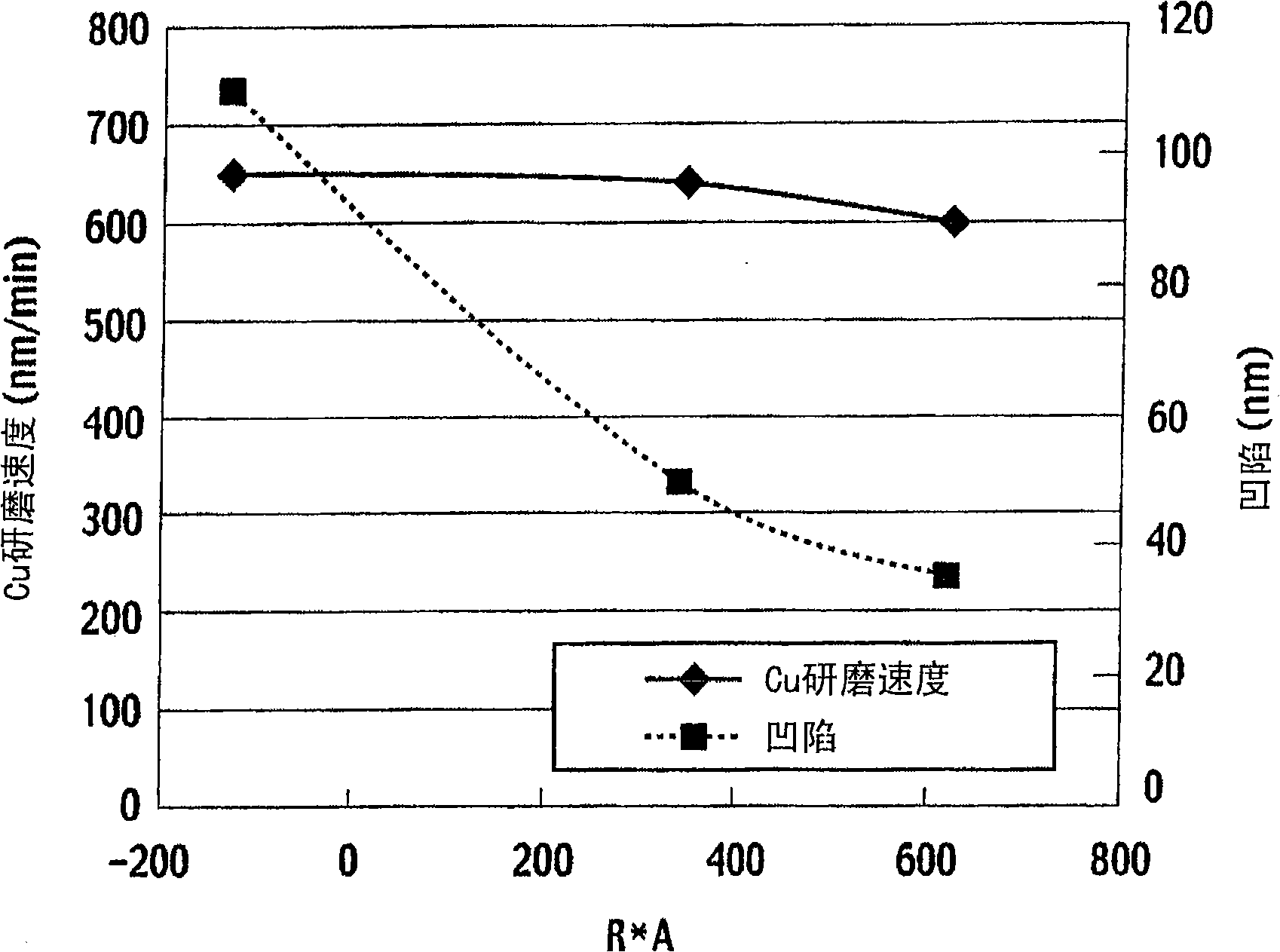

[0063] In Examples 1 to 4 and Comparative Example 1, CMP was performed on the substrate to be polished under the following polishing conditions using the above-mentioned metal polishing solution 1 to which abrasive particles having di...

Embodiment 5 and comparative example 2

[0064](Example 5 and Comparative Example 2: Polishing liquid 2 for metal)

[0065] The metal grinding liquid 2 that uses is to contain the following 0.5 mass % oxide metal dissolving agent, the nitrogen-containing cyclic compound (metal corrosion inhibitor) below 0.3 mass %, the water-soluble macromolecule (additive) below 0.5 mass %, 10 Mass % or less hydrogen peroxide (oxidizing agent) and water. In addition, the primary particle diameter is within the range of ±10% of the average value described in Table 1, and the secondary particle diameter is within the range of ±15% of the average value described in Table 1, and the surface potentials described in Table 1 are different. Grinding particles are added to the metal grinding liquid 2 .

[0066] In Example 5 and Comparative Example 2, CMP was performed under the following polishing conditions using the aforementioned metal polishing solution 2 to which abrasive particles having different surface potentials were added.

Embodiment 6 and comparative example 3

[0067] (Example 6 and Comparative Example 3: Polishing liquid 3 for metal)

[0068] The metal polishing solution 3 used contains not more than 1% by mass of an organic acid (a metal oxide dissolver), not more than 2% by mass of a water-soluble polymer (additive), not more than 10% by mass of hydrogen peroxide (an oxidizing agent) and water. In addition, the primary particle diameter is the average ± 10% of the average value recorded in Table 1, the secondary particle diameter is within the range of the average ± 15% of the average value recorded in Table 1, and abrasive particles with different surface potentials are added to the above-mentioned abrasive particles. In the metal grinding liquid 3 mentioned above.

[0069] In Example 6 and Comparative Example 3, CMP was performed on the substrate to be polished under the following polishing conditions using the above-mentioned metal polishing liquid 3 to which the polishing particles described in Table 1 having different surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com