Circulation processing method for poultry and livestock manure

A technology for recycling and excrement, which is applied in the direction of bio-organic part treatment, excretion fertilizer, anaerobic digestion treatment, etc., can solve the problems of environmental pollution, poor economy, and large loss of fertility, and achieve no environmental pollution, reduce stacking sites, The effect of reducing stacking cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

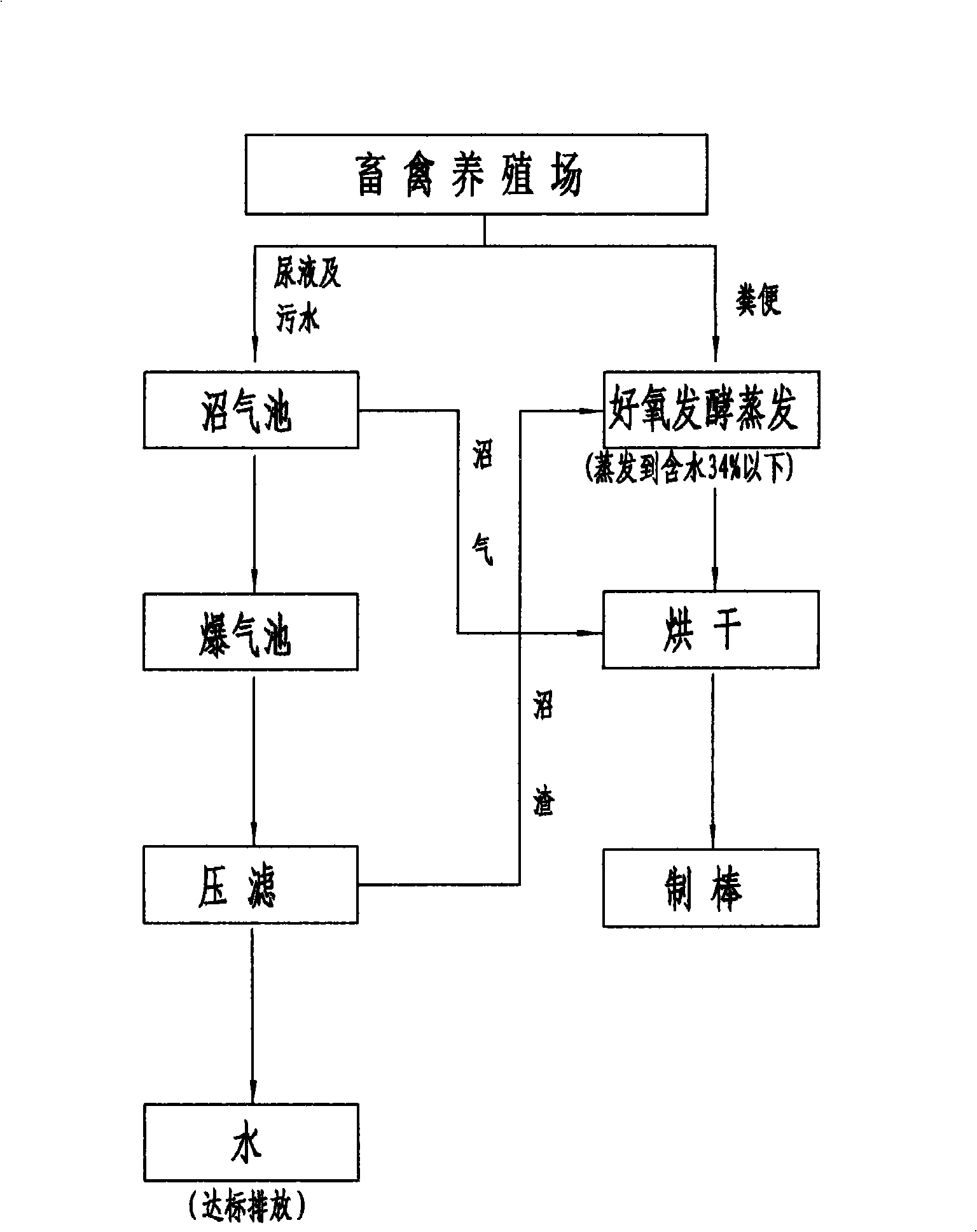

[0021] Such as figure 1 As shown, a recycling treatment method of poultry excrement, the key point is to divide the accumulated poultry excrement of poultry farms into liquid waste mainly composed of urine and sewage and solid waste mainly composed of feces. The liquid waste is transported to the digester device for anaerobic fermentation to produce biogas and biogas residue. The biogas residue is degassed through the degassing tank, and then filtered and then transported to the compost turner device together with solid waste for good Oxygen fermentation, the water after pressure filtration is purified, such as using filter materials for filtration or activated carbon materials for adsorption treatment, and then discharged after deodorization. The biogas is used as the heat source energy of the drying device in the drying process, and the sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com