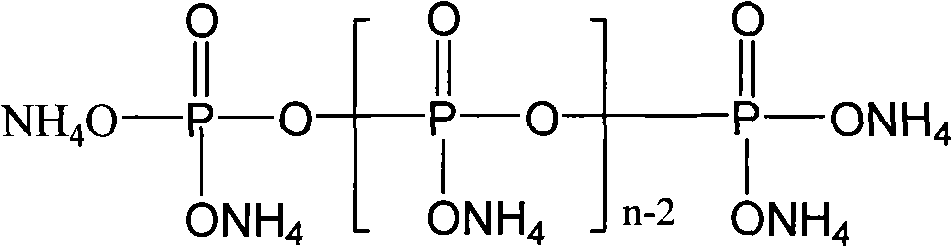

Ammonium polyphosphate, montmorillonite nano complex and preparation thereof

A nano-composite, ammonium polyphosphate technology, applied in the direction of fire-resistant coatings, can solve the problems of high water solubility of ammonium polyphosphate and low yield of ammonium polyphosphate, and achieve the effects of low cost, improved flame retardant effect, and simple raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

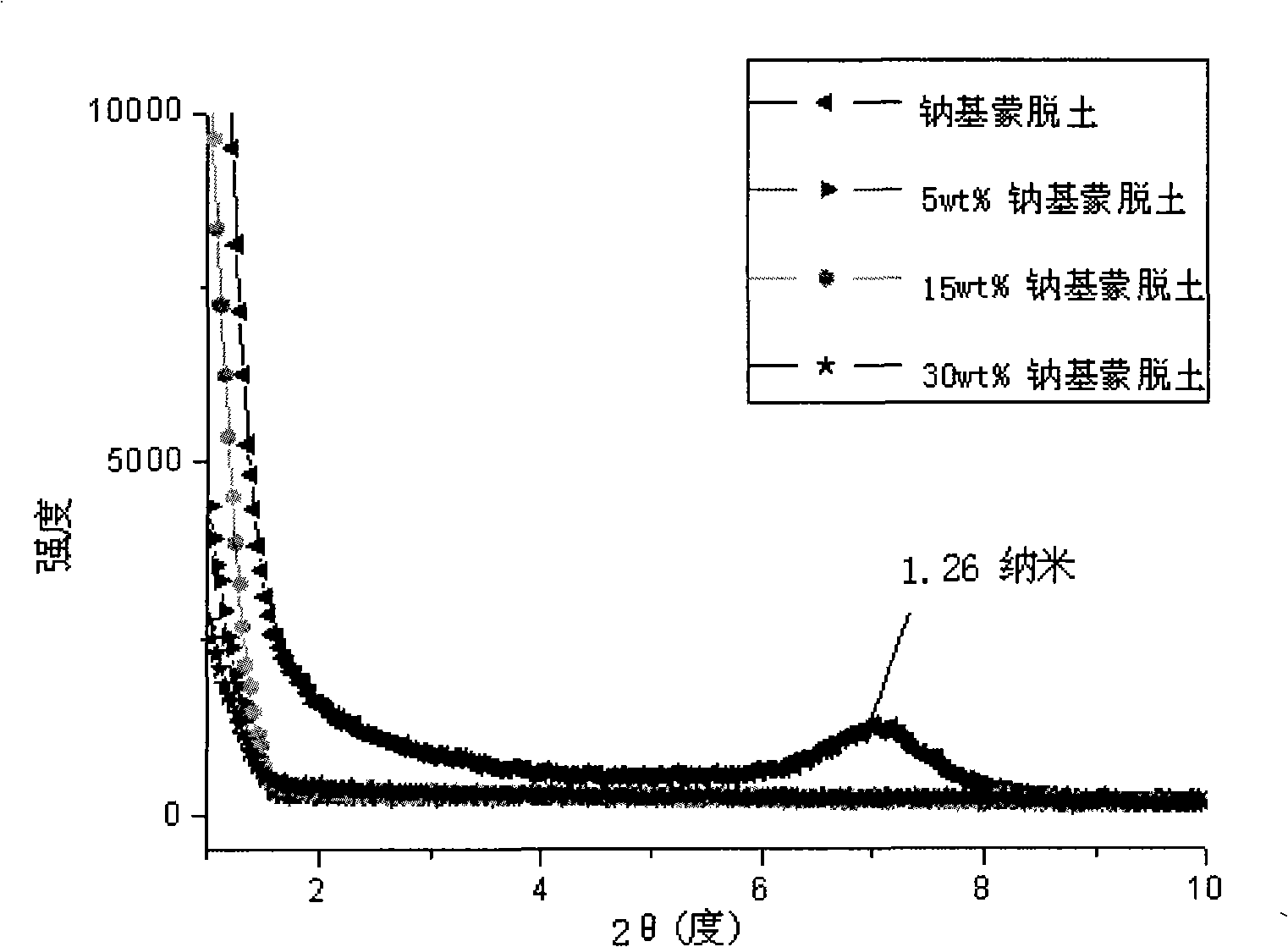

[0043]Example 1: 1059 grams of phosphorus pentoxide, 984 grams of diammonium hydrogen phosphate, and 134 grams of urea were added to a reaction kettle, stirred, pulverized, and ground. Then heat up 218 grams of montmorillonite in the reaction ax to 250°C and start passing ammonia, maintain the ammonia pressure as normal pressure, then continue to heat up to 300°C, and ammoniate for 90 minutes to obtain ammonium polyphosphate and montmorillonite nanocomposites, wherein The montmorillonite was completely exfoliated, and the purity of the crystalline type I ammonium polyphosphate was 100%.

Embodiment 2

[0044] Example 2: 923 grams of phosphorus pentoxide, 858 grams of diammonium hydrogen phosphate, and urea 117 are added to the reactor, and when the temperature is raised to 100° C., 190 grams of montmorillonite is added to the reaction system, and the temperature is raised to 250° C. The ammonia pressure is 0.1 MPa, and then continue to heat up to 300°C, and ammonium for 90 minutes to obtain ammonium polyphosphate and montmorillonite nanocomposite, in which the montmorillonite is completely peeled off, and the purity of crystalline type I ammonium polyphosphate is 100%.

Embodiment 3

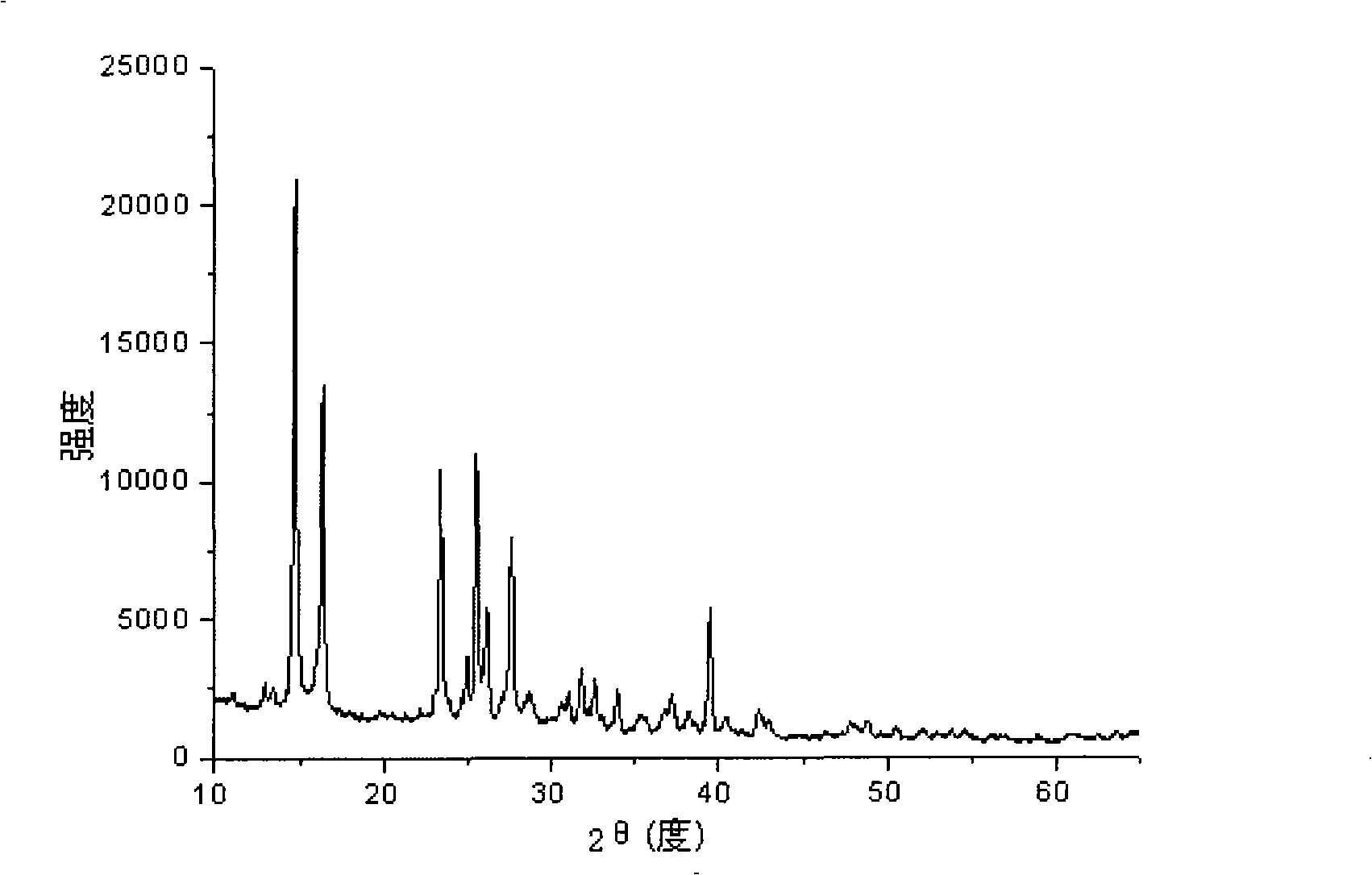

[0045] Example 3: 472 grams of phosphorus pentoxide, 439 grams of diammonium hydrogen phosphate, and 60 grams of urea were added to the reactor, and when the temperature was raised to 120° C., 146 grams of montmorillonite was added to the reaction system, and the temperature was raised to 250° C. to start passing ammonia. Maintain ammonia pressure to be normal pressure, continue to heat up to 300 ℃ then, ammonium 90 minutes, the purity of the crystalline type I ammonium polyphosphate obtained is 100% (its X-ray diffraction pattern is as follows figure 2 shown).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com