440MPa grade niobium-containing high-strength IF steel and manufacturing method thereof

A 440MPa, high-strength technology, applied in the field of 440MPa niobium-containing high-strength IF steel and its preparation, can solve the problems of reduced formability and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

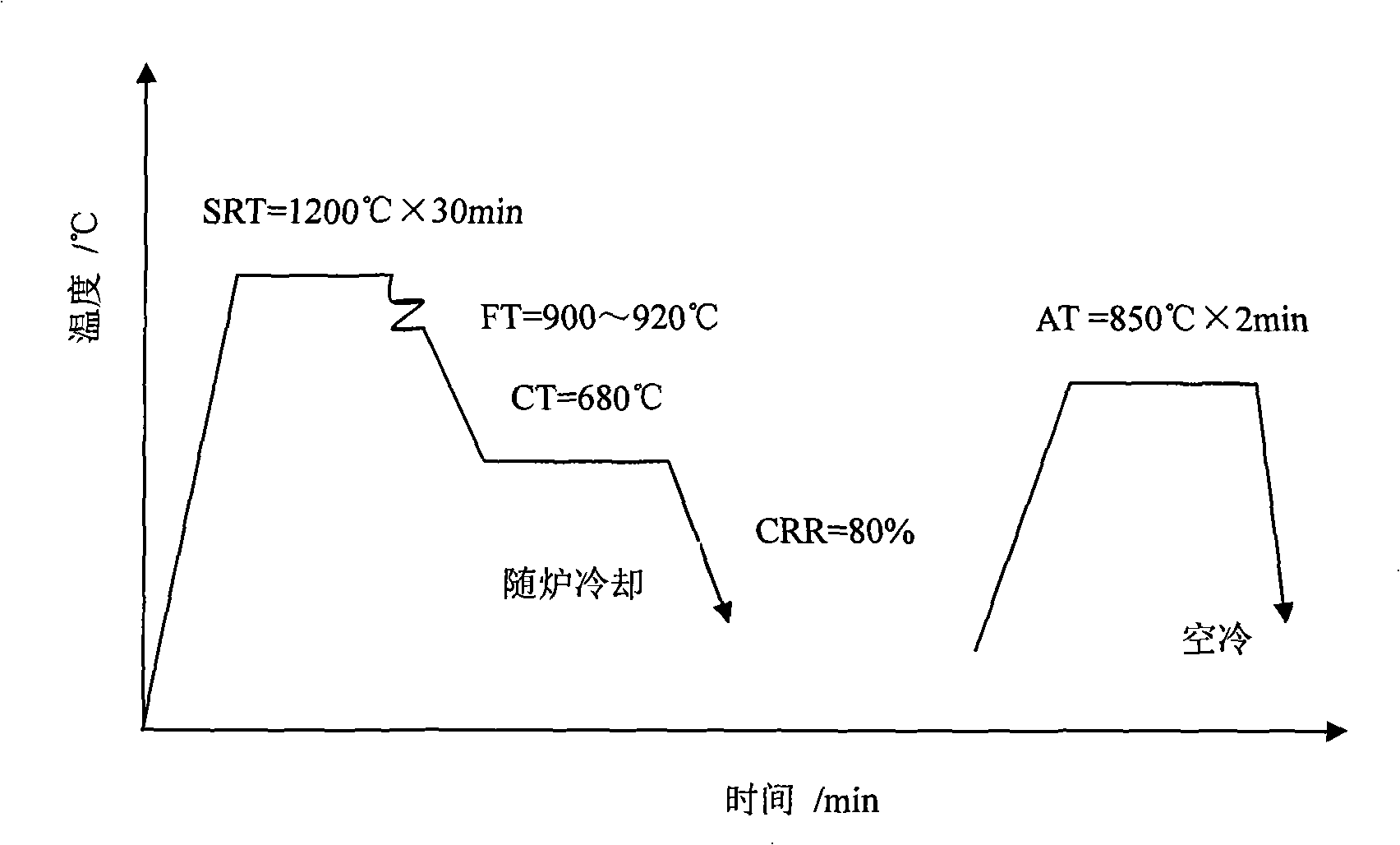

Image

Examples

Embodiment Construction

[0020] (1) The reason for the numerical limitation of the composition of the high-strength IF steel of the present invention will be described in detail below.

[0021] (1) Carbon (C) and nitrogen (N): C is 0.005% to 0.006%, N≤0.003%

[0022] The solid solution formed by carbon and nitrogen atoms in steel exists in the form of interstitial solid solution, which has a significant solid solution strengthening effect, increases yield strength and tensile strength, and increases hardness, but also significantly reduces steel plasticity and formability. and cause aging. For stamping steel, the role of nitrogen is the same as that of carbon, mainly causing yield effect and strain aging.

[0023] In order to obtain enough niobium carbonitrides, C is 0.005% to 0.006%, and N≤0.003%.

[0024] (2) Phosphorus (P) and manganese (Mn): Mn is 1.2% to 2.1%, P<0.08%

[0025] Both P and Mn are solid solution strengthening elements, when added alone, but with the increase of content, the plast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com