Optical device and method of controlling the same

A technology of optical devices and optical components, applied in the field of optical devices and controlling the optical devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

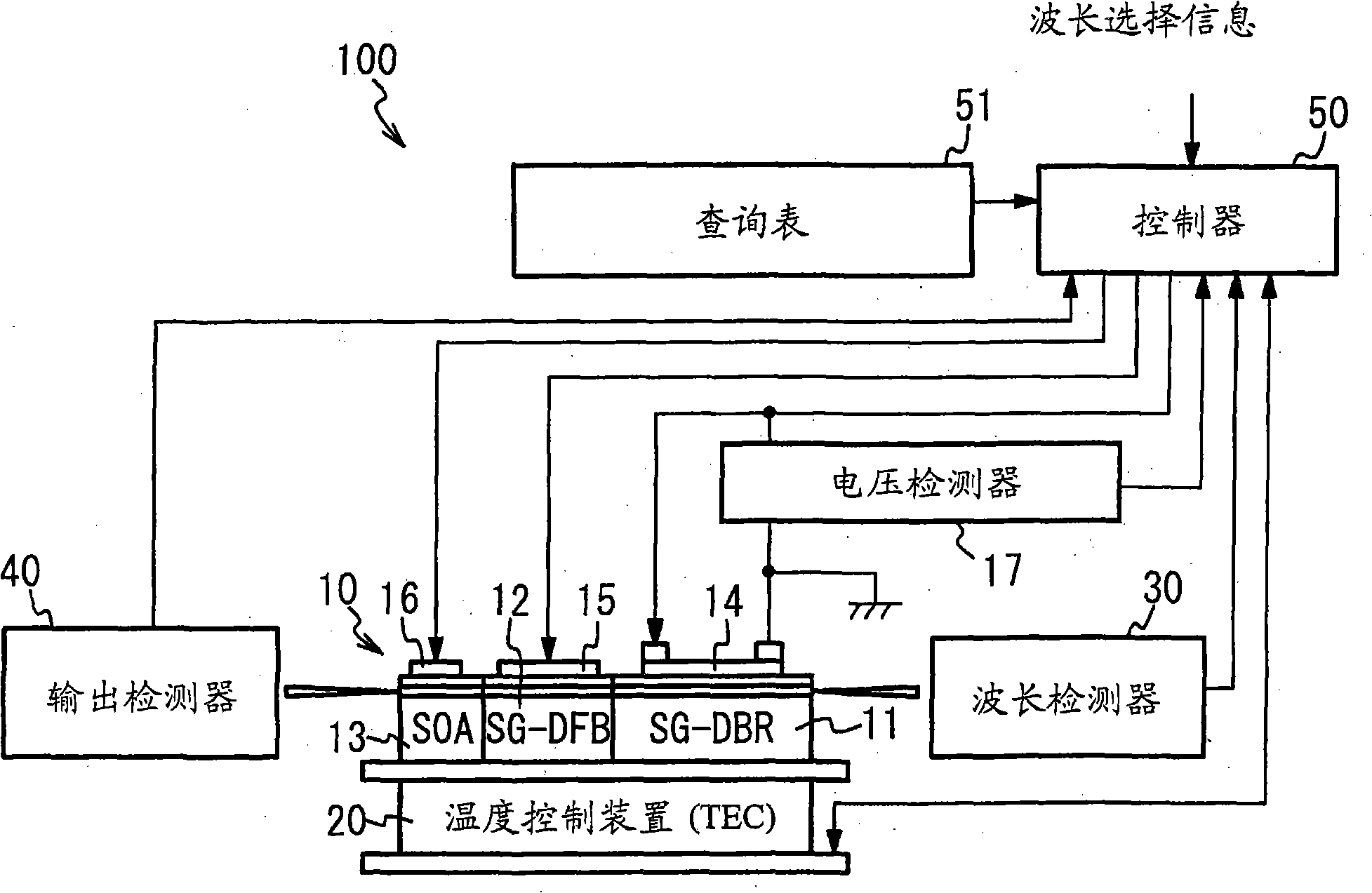

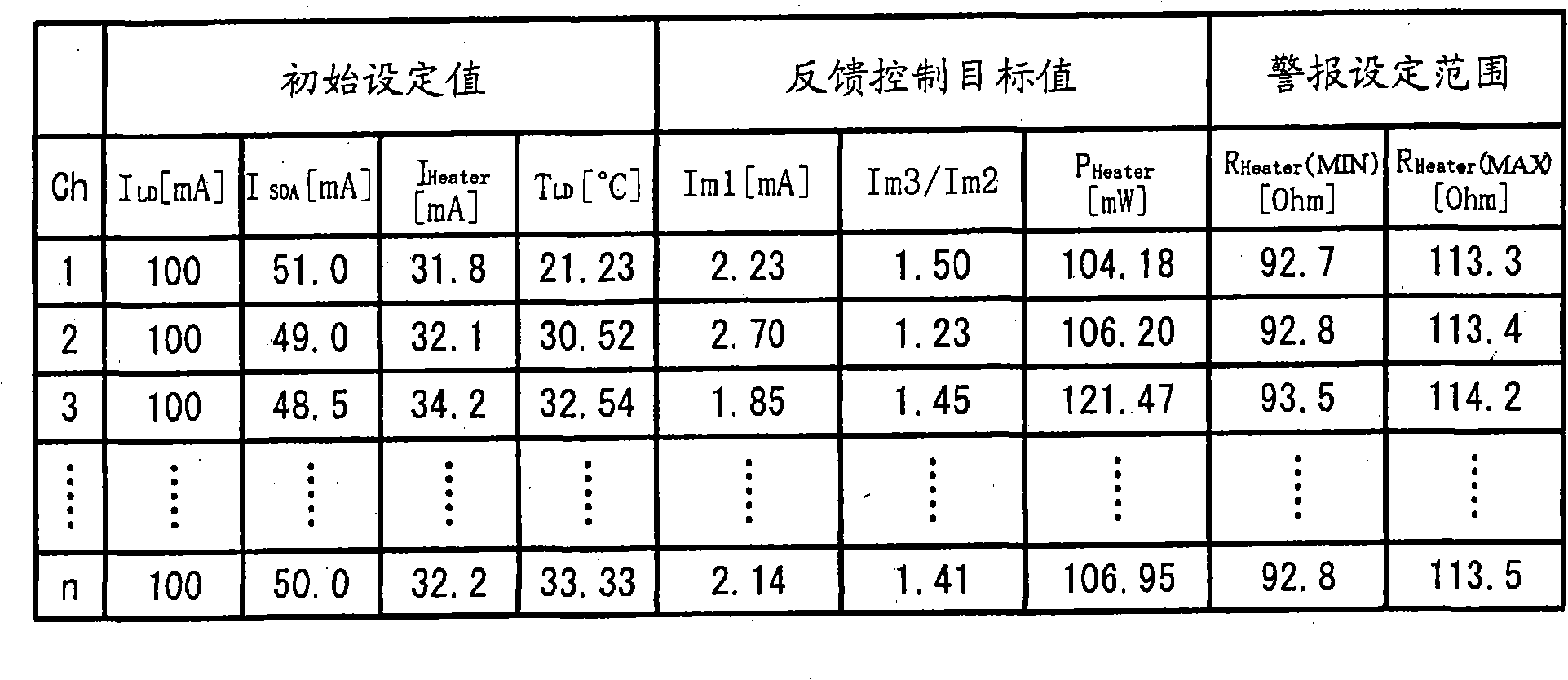

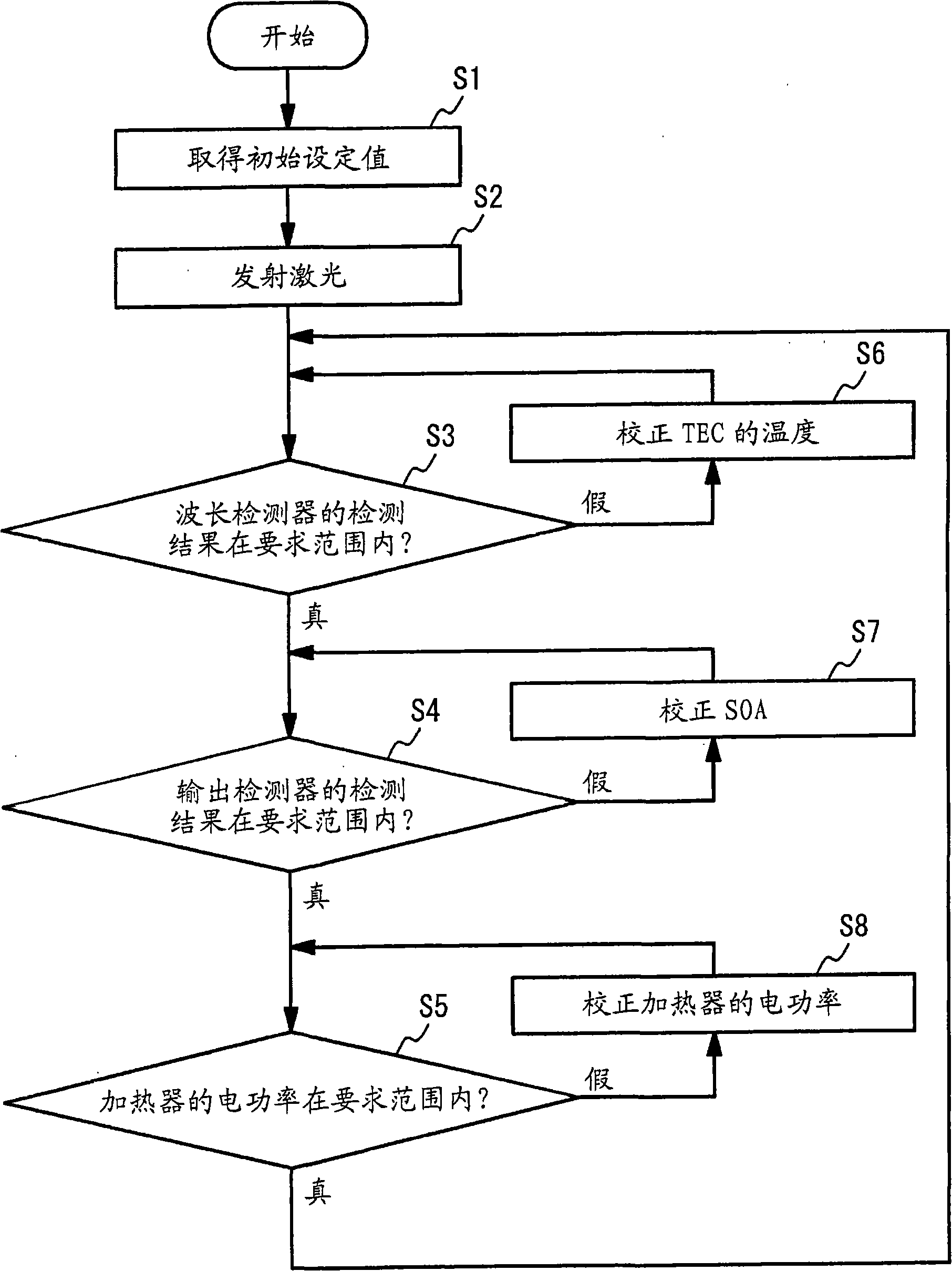

[0025] Next, a semiconductor laser as an optical element will be described. figure 1 The structures of the semiconductor laser 10 and the laser device 100 having the semiconductor laser 10 according to the first embodiment are illustrated. Such as figure 1 As shown, the laser device 100 has: a semiconductor laser 10 , a temperature control device 20 , a wavelength detector 30 , an output detector 40 and a controller 50 . The semiconductor laser 10 is mounted on a temperature control device 20 . Each component is described below.

[0026] The semiconductor laser 10 has a structure in which an SG-DBR region 11 , an SG-DFB region 12 , and a semiconductor amplifier (SOA: Semiconductor Optical Amplifier) region 13 are sequentially coupled. The SG-DBR region 11 has optical waveguides in which gratings are provided at predetermined intervals. That is, the optical waveguide of the SG-DBR region 11 has a first region having a diffraction grating, and a second region optically con...

no. 2 approach

[0049] In the second embodiment, a semiconductor laser having the aforementioned CSG-DBR will be described. Figure 5 The structures of the semiconductor laser 10a and the laser device 100a having the semiconductor laser 10a are illustrated. Such as Figure 5 As shown, the semiconductor laser 10 a has a CSG-DBR region 11 a instead of the SG-DBR region 11 . In this embodiment, the CSG-DBR region 11a has three segments with a combination of gratings and spacers. Therefore, for each segment, three heaters 14a, 14b, and 14c are provided on the CSG-DBR region 11a. And for each heater, voltage detectors 17a, 17b, and 17c are provided.

[0050] In this embodiment, while the electric power supplied to each heater is feedback-controlled to be kept constant based on the detection result of each voltage detector, the calorific value of each heater can be kept constant. Therefore, the semiconductor laser 10a acquires a desired oscillation wavelength.

[0051] The number of gratings a...

no. 3 approach

[0053] The present invention can be applied to other optical elements than semiconductor lasers. For example, the invention can be applied to mach-Zehnder optical switches. Such optical switches are used in switching systems such as optical cross-connects.

[0054] Figure 6 The structure of the optical switch 200 according to the third embodiment is illustrated. Such as Figure 6 As shown, the optical switch 200 is made of a material having a thermo-optic effect such as a silicon-based material. The optical switch 200 has a mach-Zehnder interference structure having a first waveguide 201 and a second waveguide 202 . The optical switch 200 is provided on the temperature control device 210 . Thus, the temperature control device 210 controls the temperature of its various components.

[0055] The optical switch 200 has a heater 203 . The heater 203 heats the second waveguide 202 . This results in a change in the phase difference between the light propagating in the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com