Hatching machine and working method of hatching machine

A working method and box technology, applied in the hatchery field, can solve problems such as the inability to seal the box, achieve uniform temperature field, save construction costs, and achieve good mixing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

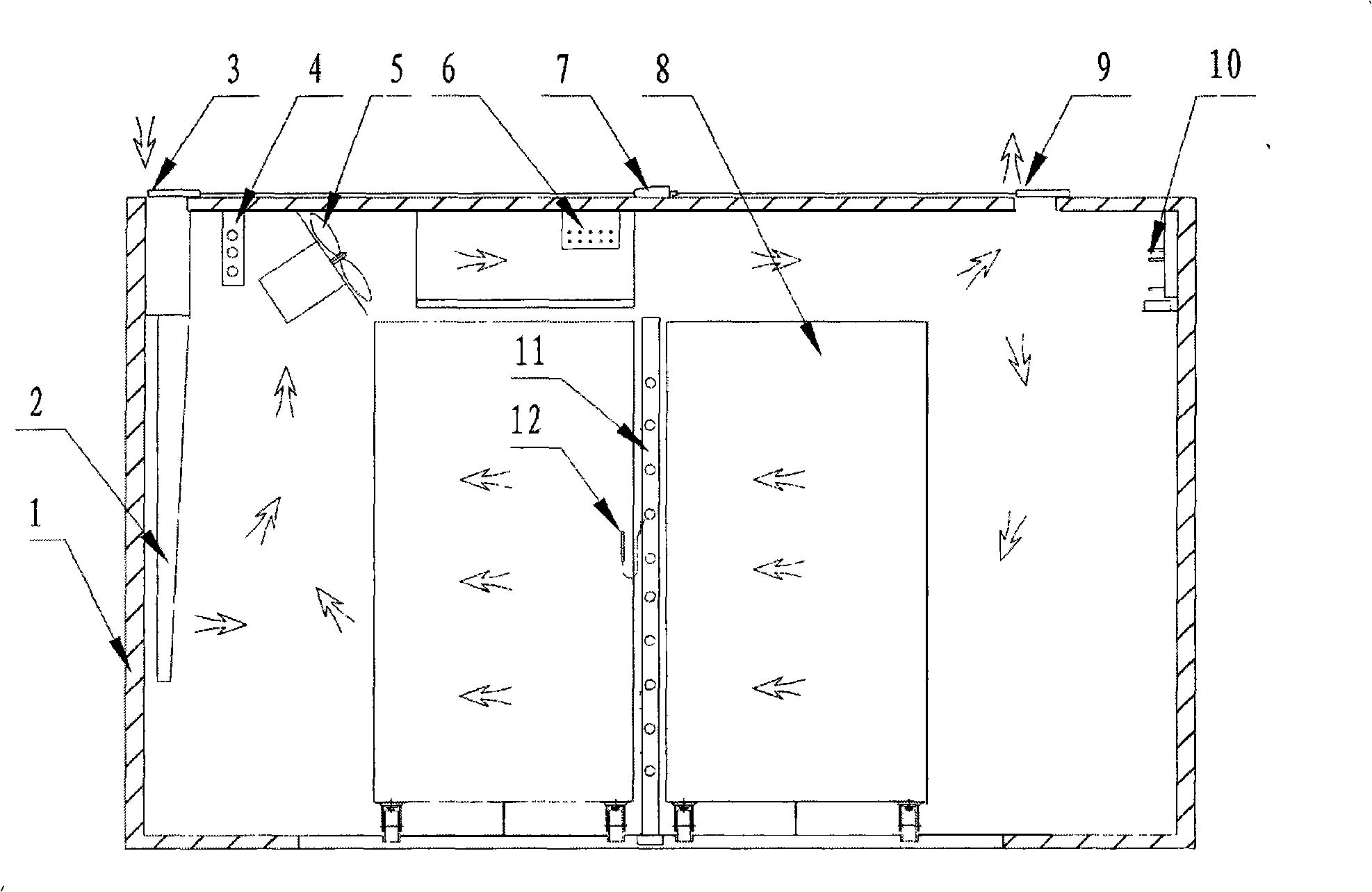

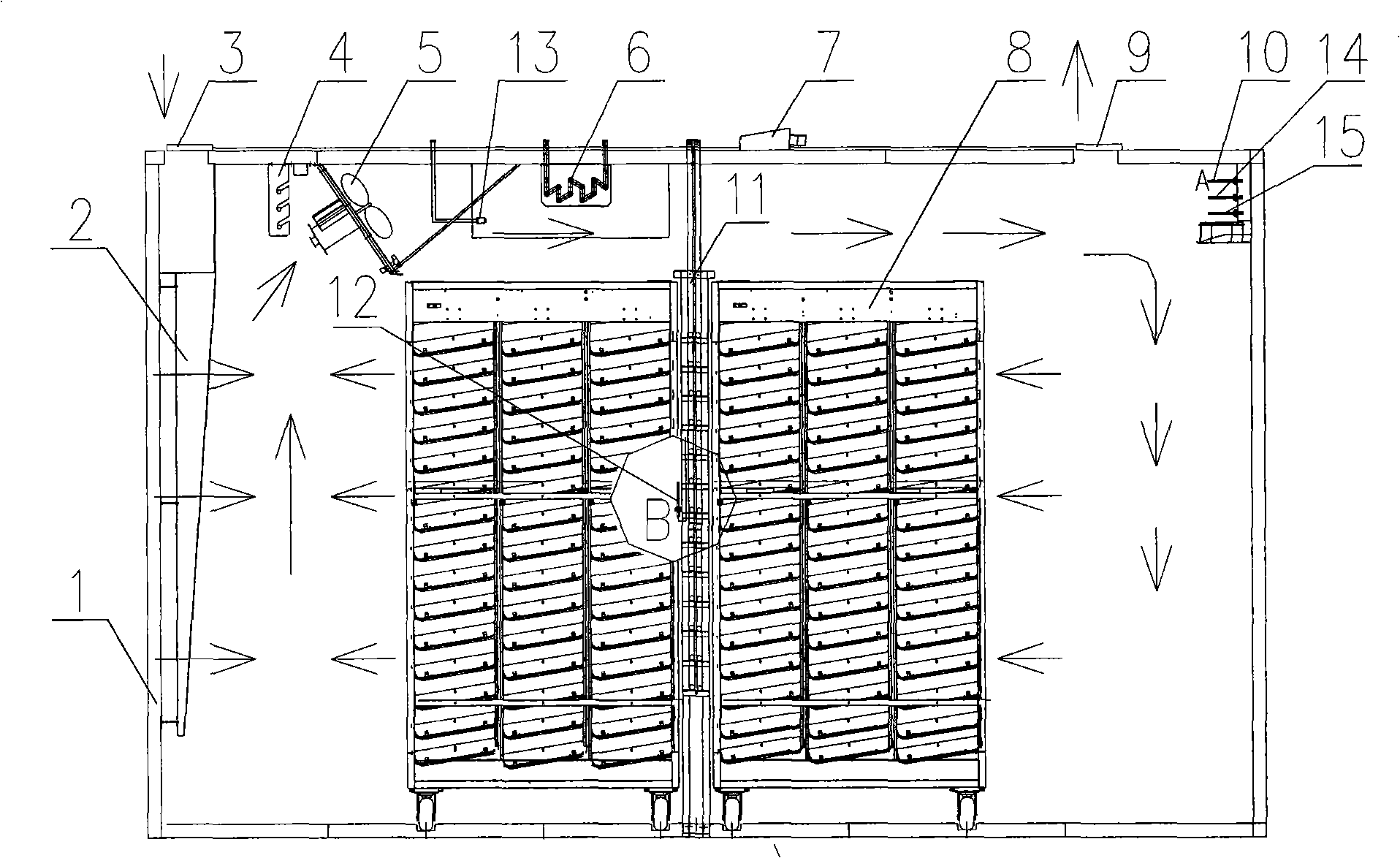

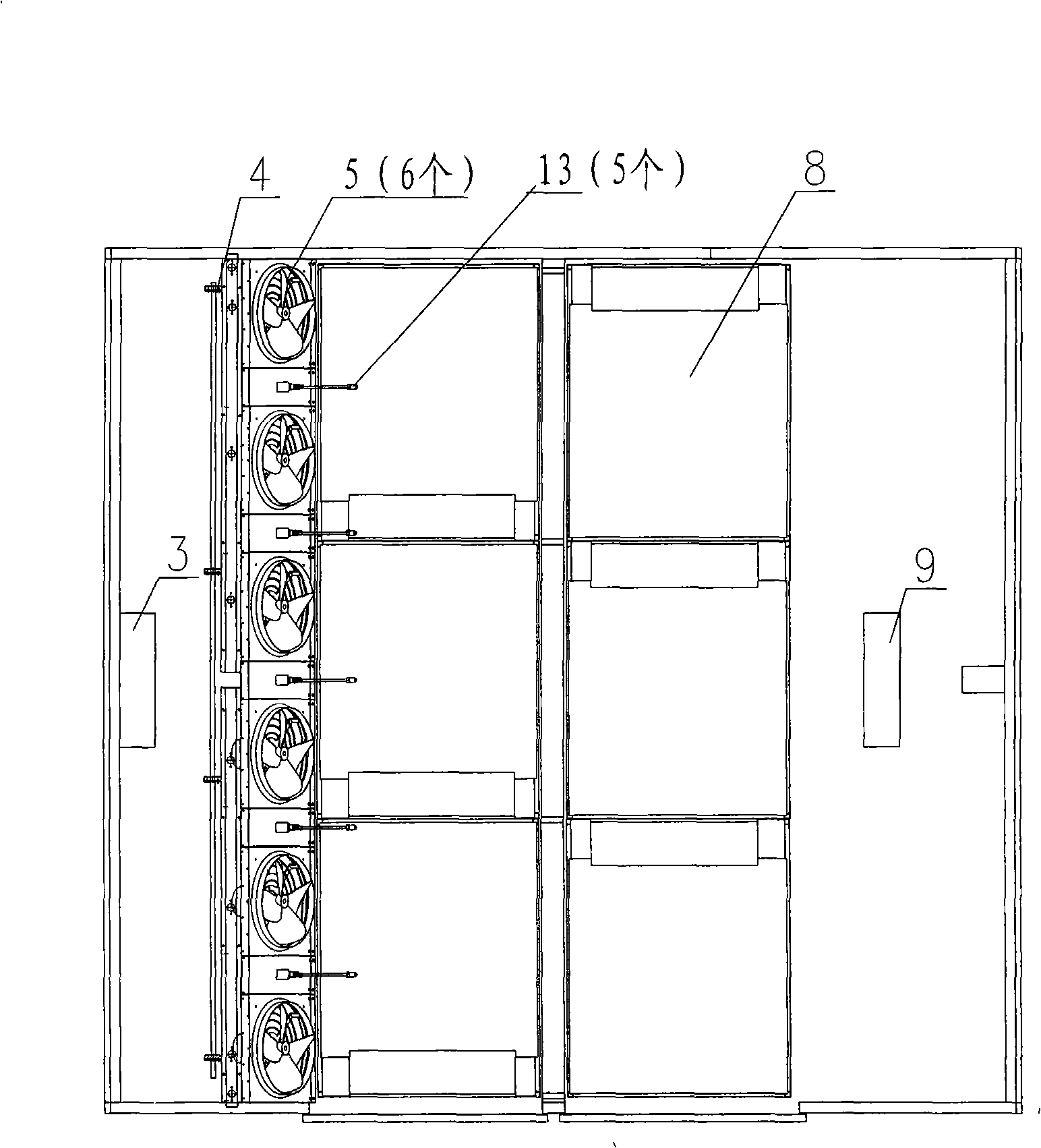

[0052] figure 1 It is a structural schematic diagram of the all-in-all-out incubator of the present invention.

[0053]In the figure, box 1; balanced air inlet pipe 2; air inlet 3; heating pipe 4; fan 5; upper water cooling pipe 6; damper drive device 7; Pipe 11; temperature sensor B12; balanced air inlet pipe 2 is located on one side of the box body 1, close to the side wall of one side. The top of the balanced air inlet pipe 2 is connected to the air inlet 3 . The heating pipe 4 is installed on the top of the box body 1 and is adjacent to the balanced air inlet pipe 2 . The fan 5 is installed on the top of the casing 1 and is adjacent to the heating pipe 4 . The upper water-cooling pipe 6 is installed on the top of the casing 1, approximately in the middle. Damper driving device 7 is contained in the middle position of the top of casing 1. Egg rack car 8 is positioned at the middle part of casing 1. The air outlet 9 is located at the top of the opposite side of the box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com