Refining method by in situ extraction of inclusion content in melting steel

A technology of inclusions and molten steel, which is applied in the refining field of in-situ extraction of inclusions in molten steel, can solve problems such as difficulty in realizing large-scale industrial production of molten steel, insufficient refining process of molten steel, and difficulty in achieving zero-inclusion molten steel, etc., to reduce production costs , Efficient removal, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

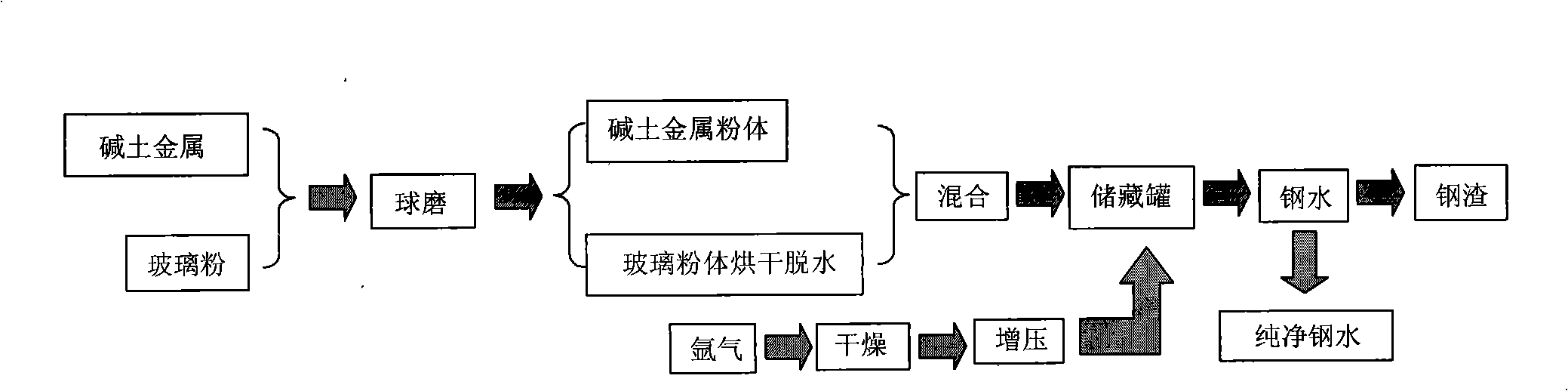

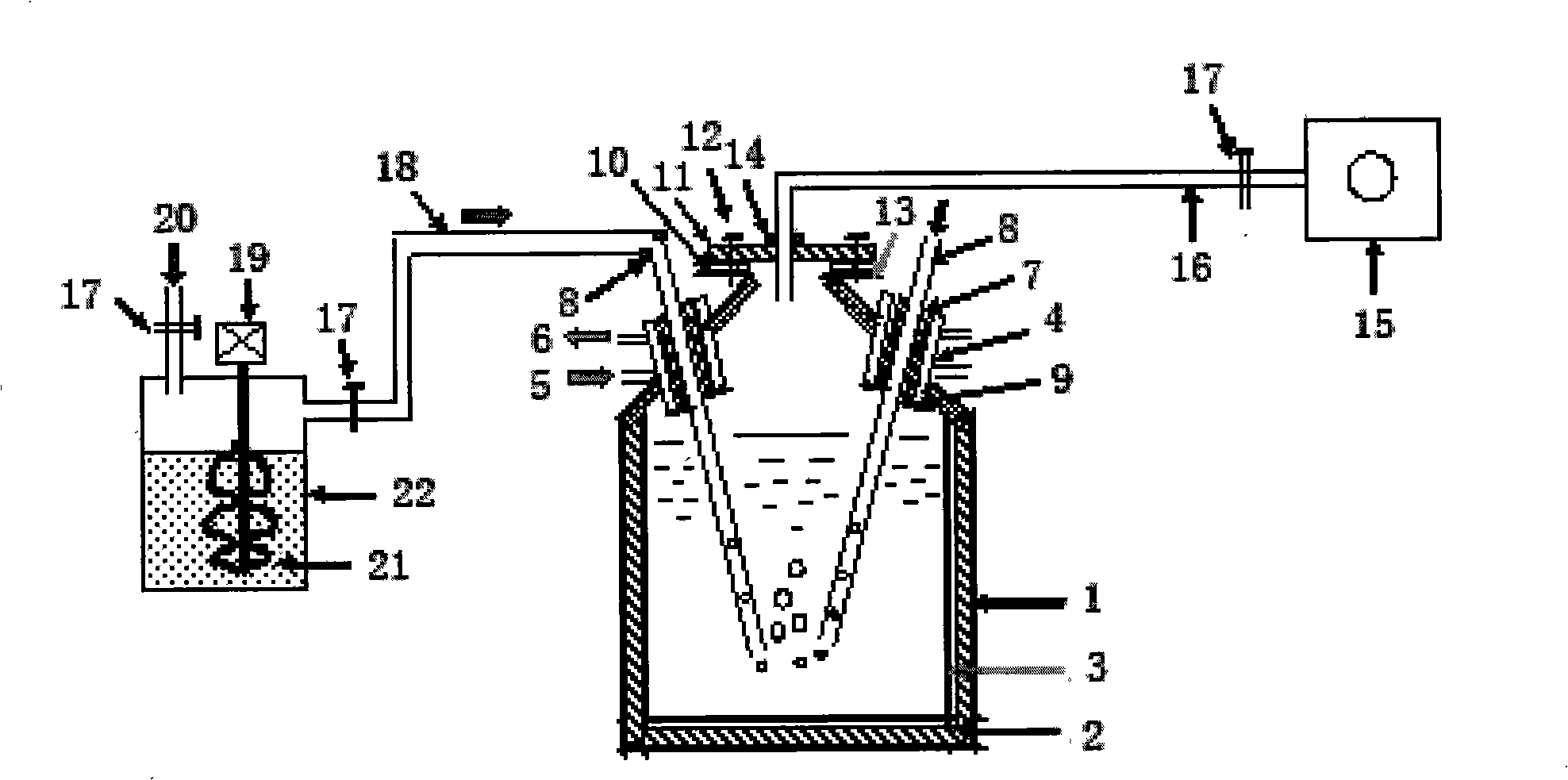

[0056] see figure 1 , figure 2 and image 3 1Kg of alkaline earth metal aluminum and 1Kg of magnesium are ball-milled into powder with a vacuum ball mill, and the particle diameter is about 60-100 mesh. Use an ordinary ball mill to grind the silicic acid glass powder B into a powder. The glass powder B uses 5Kg of cheap serpentine ore powder. Its chemical structure is Mg6[Si4O10](OH)8, of which MgO accounts for 40- 45%, SiO 2 40-45%, H 2 O accounts for 10-20%. Grind into 70-100 mesh powder, and dry and dehydrate.

[0057] Then the alkaline earth metal balls and the serpentine ore powder are mixed evenly and put into the storage tank 22 . The argon gas is dehydrated through a desiccant, dried with molecular sieves, compressed and pressurized to 7Mpa by a compressor. The compressed argon gas passes through the above-mentioned mixed powder storage tank 22 . The compressed gas takes the powder away, and then sprays it into the 50T molten steel G at 1600 degrees. The proce...

Embodiment 2

[0073] In addition to using a vacuum ball mill to grind 2Kg of alkaline earth metal aluminum and 2Kg of magnesium into powder, the particle diameter is about 60-80 mesh. Use an ordinary ball mill to grind the siliceous glass powder into a powder. The glass powder uses 10Kg of cheap serpentine ore powder and grinds it into a powder of 100-120 mesh. The steel is 50T, and other processes are shown in the example. 1. In situ extraction of inclusions in molten steel.

Embodiment 3

[0075] In addition to using a vacuum ball mill to grind 1Kg of alkaline earth metal aluminum and 2Kg of magnesium into powder, the particle diameter is about 80-100 mesh. The silicic acid glass powder is ball-milled into powder with an ordinary ball mill, and the glass powder adopts 8Kg of cheap serpentine mineral powder, and is ground into a 120-140 mesh powder, and the steel is 45T, and other processes are the same as in Example 1 . In situ extraction of inclusions in molten steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com