Method for testing orientation silicon iron coating surface tension stress

A technology of grain-oriented silicon steel and tensile stress, applied in the field of grain-oriented electrical steel testing, can solve the problems of high cost, high test environment requirements, and long measurement cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

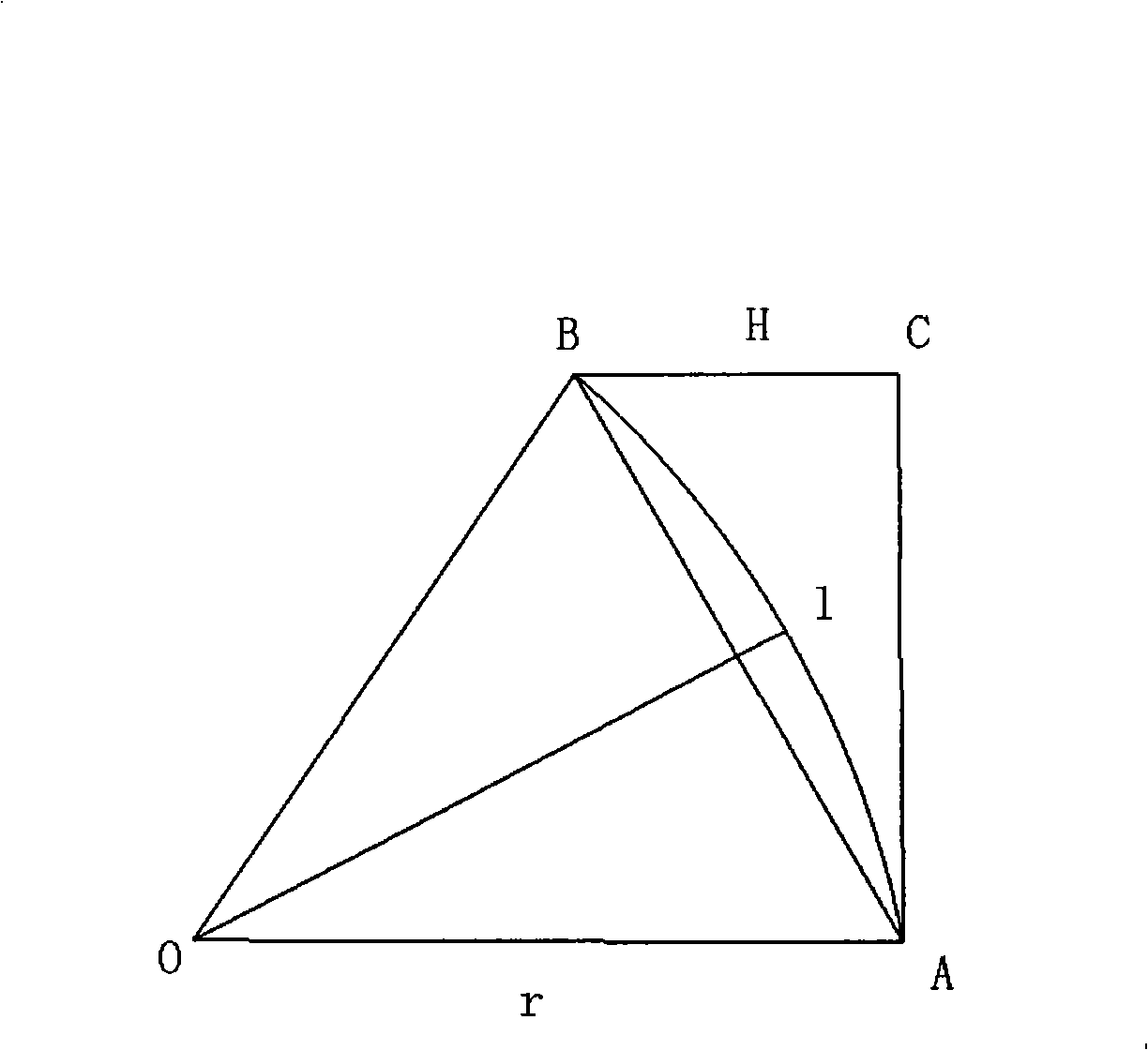

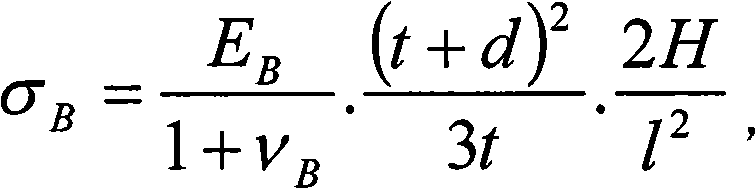

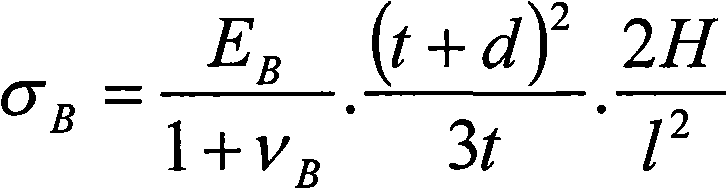

Image

Examples

Embodiment

[0061] Randomly select several pieces of grain-oriented silicon steel samples, and use this method for testing. The results are as follows:

[0062]

[0063]It can be seen from the table that under different coating amounts, a series of tensile stress and iron loss reduction values can be obtained by changing the pickling time. These values are basically the same as the actual tensile stress iron loss reduction values experienced in practice.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com