Wave straightly-drive type straight-line magneto resistance power generation system

A power generation system and direct drive technology, applied in control systems, ocean energy power generation, electromechanical devices, etc., can solve the problems of poor reliability, high cost and uneconomical, etc., and achieve the effect of avoiding corrosion, low cost and good fault tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

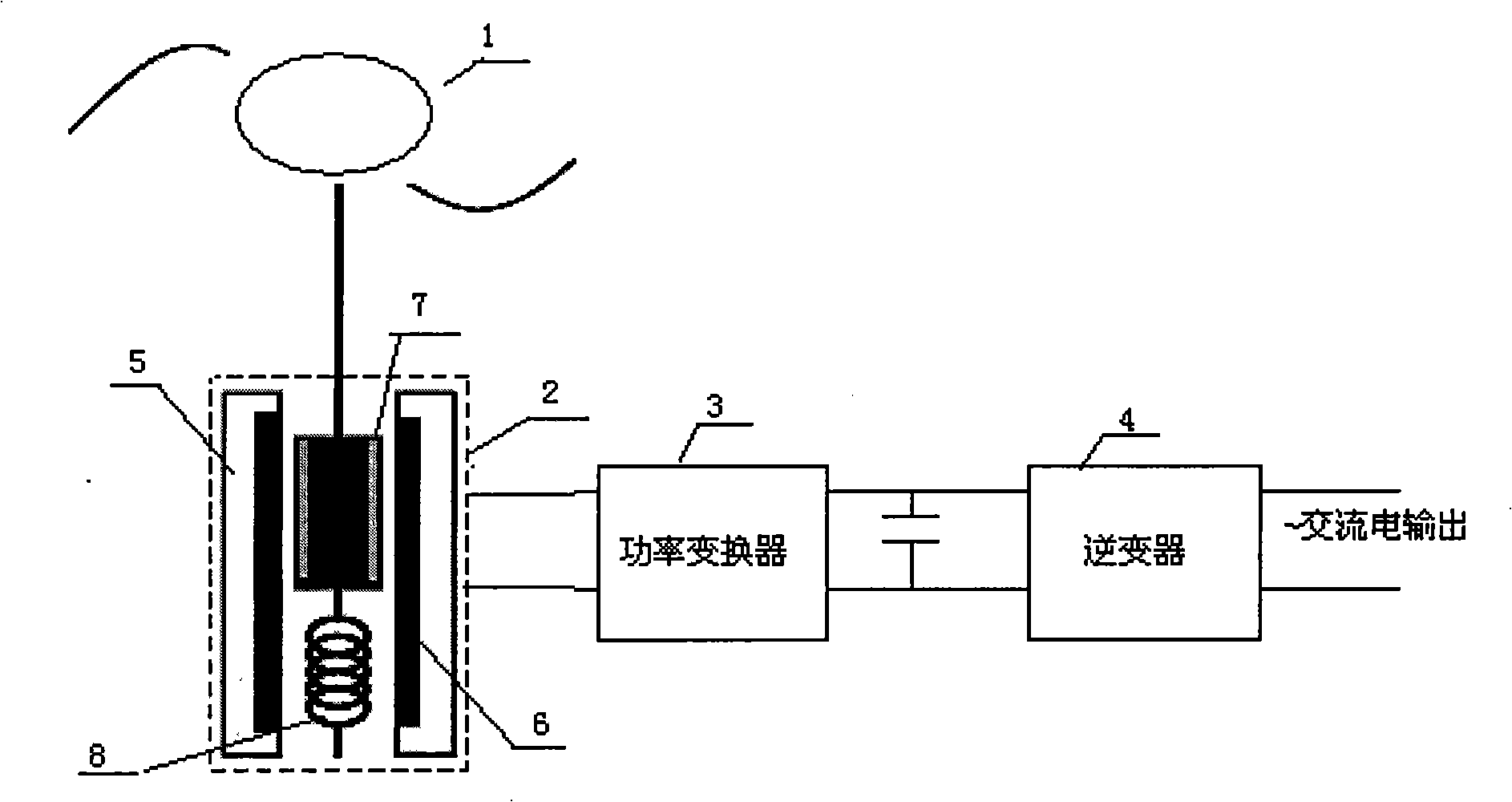

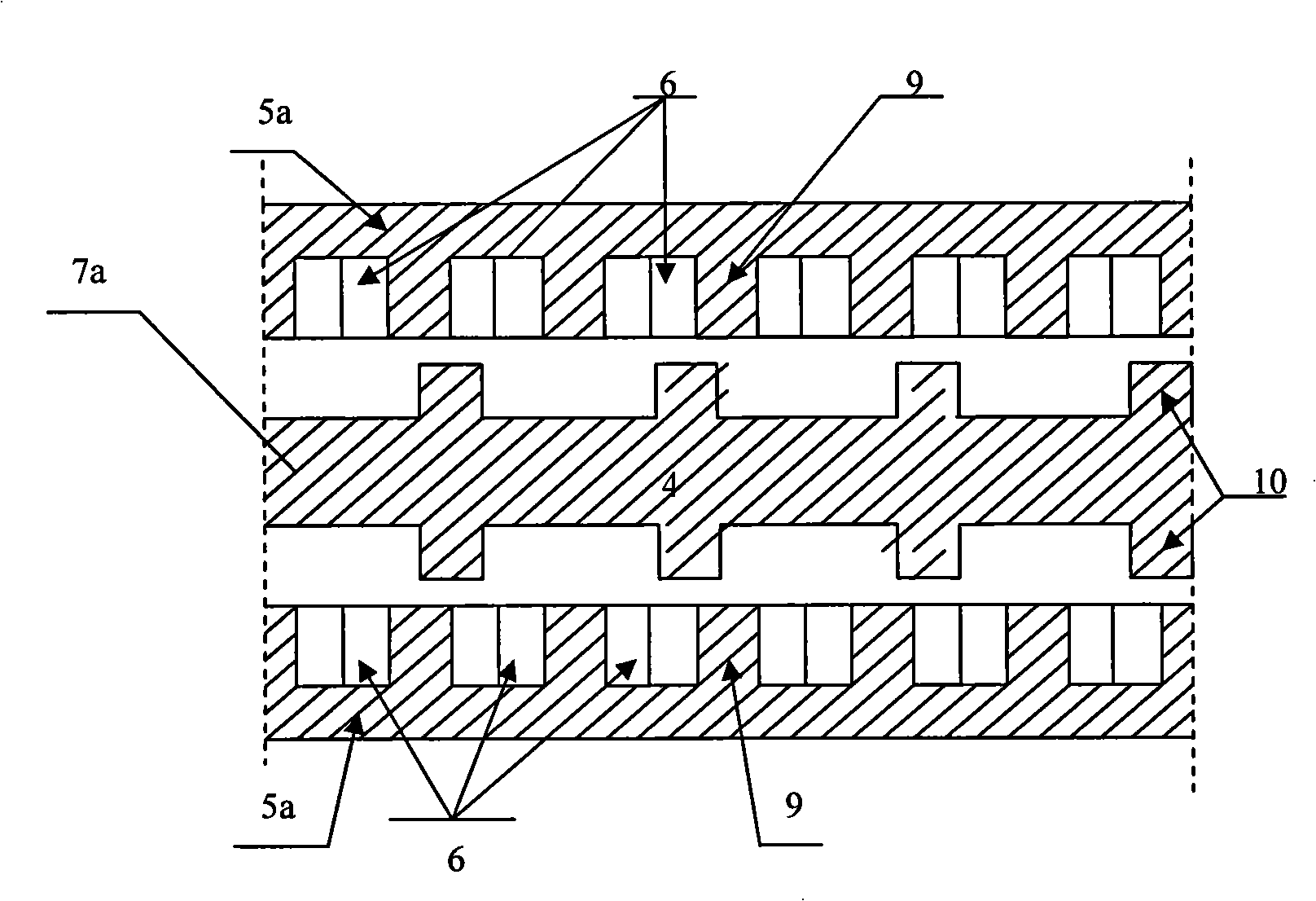

[0016] combine 1, figure 2 and Figure 4 , The wave power generation system of the present invention includes a wave energy absorbing device 1 , a linear switched reluctance generator 2 , a power conversion unit 3 and an inverter unit 4 . The linear switched reluctance generator 2 is composed of an initial pole 5a made of silicon steel sheets, a three-phase winding 6 for the initial pole, and a secondary pole 7a made of silicon steel sheets with tooth grooves. The lower end of the mover 7 is installed on the base of the generator through a spring 8 , and the upper end of the mover 7 is elastically connected with the wave energy absorbing device 1 . The whole power generation system can be installed on the seabed by the container, and the motion of the wave moves up and down with the wave energy absorbing device 1 placed underwater or on the water surface during operation, thereby driving the mover 7 of the linear switched reluctance generator 2 to move up and down. The wave...

Embodiment 2

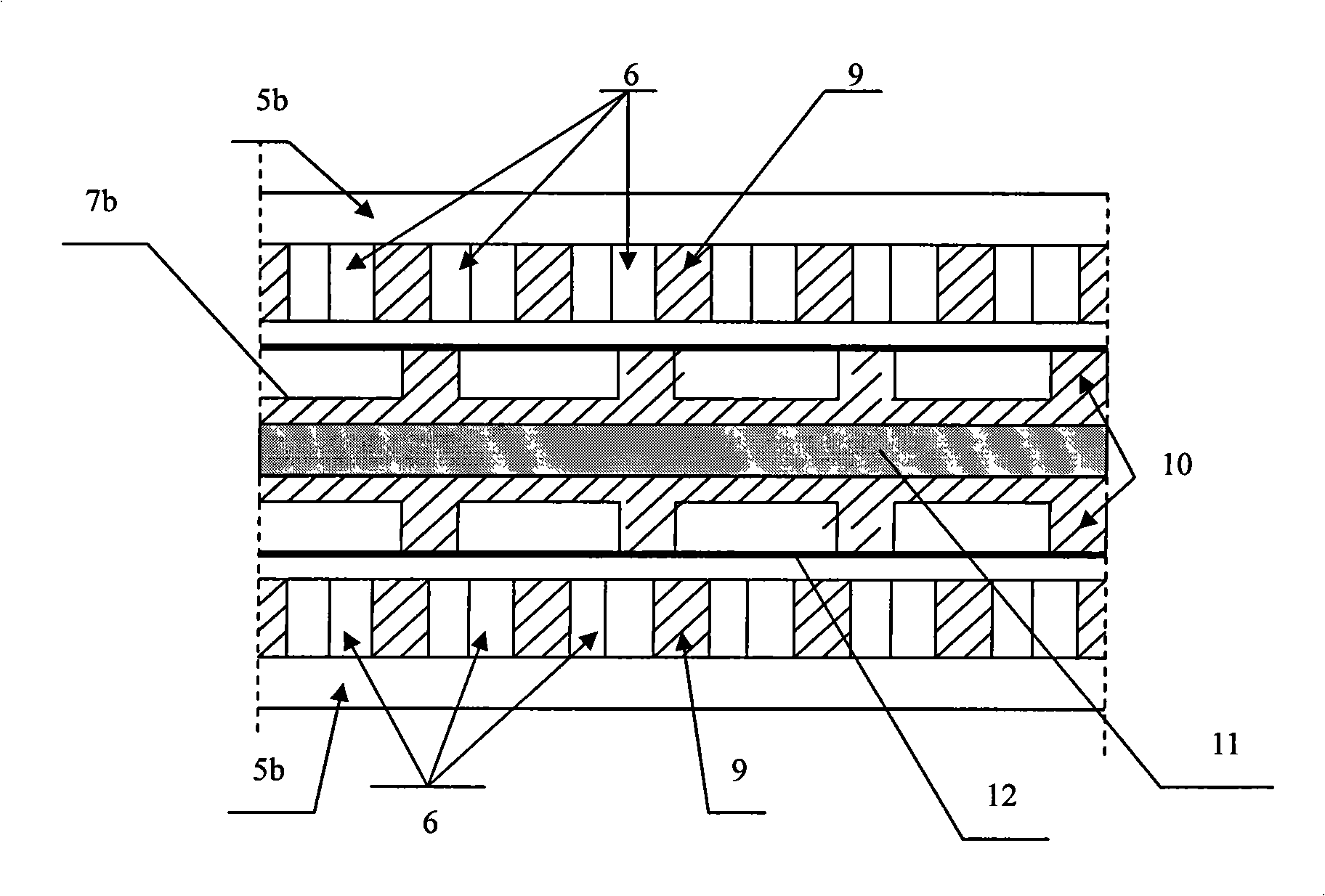

[0018] combine figure 1 , image 3 and Figure 4 , on the basis of Example 1, the figure 2 The double-sided structure of the primary pole iron core and the secondary pole mover shown is replaced by image 3 The cylindrical structure shown. The primary pole iron core lamination of the cylindrical switched reluctance linear motor is a cylindrical iron core 5b, and the primary pole winding 6 is a cake-shaped coil, which are laminated in the cylindrical iron core wiring groove in turn; the secondary pole mover is made of silicon steel The sheets are stacked into an annular iron core 7b with tooth grooves, and are tightly fitted on the outer diameter of a non-magnetic solid metal cylinder 11, and the outer layer is tightened by a non-magnetic metal thin-walled cylinder 12. Compared with the unilateral structure and double-sided structure, the advantage of the cylindrical structure is less magnetic flux leakage and higher efficiency.

[0019] The working principle of the linea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com