Coating method of metal coat with stereo pattern

A metal coating and pattern technology, which is applied in the process of producing decorative surface effects, decorative arts, special artistic surface treatment, etc. The effect of low cost and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

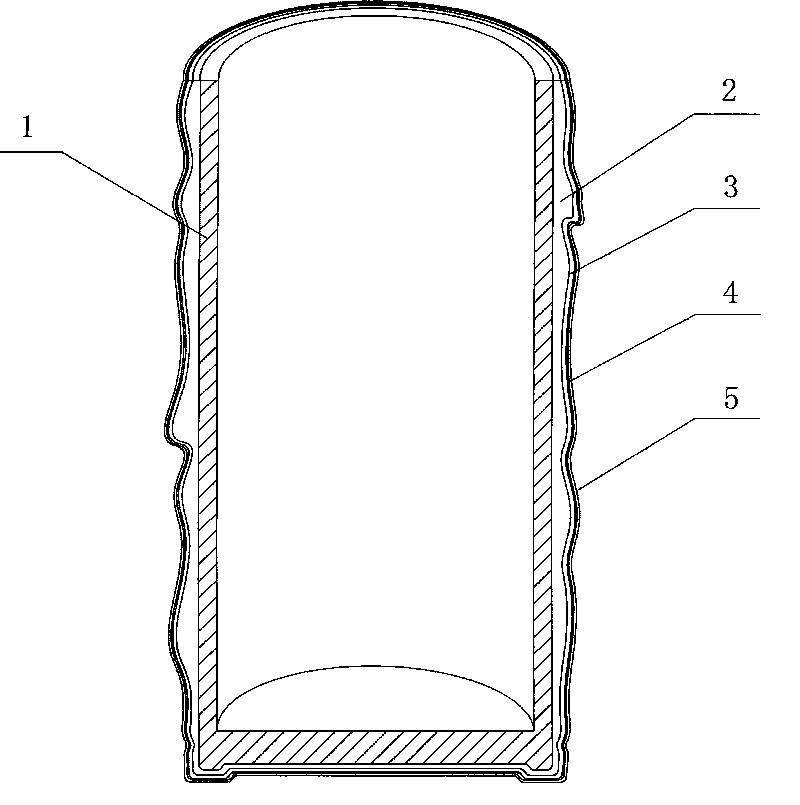

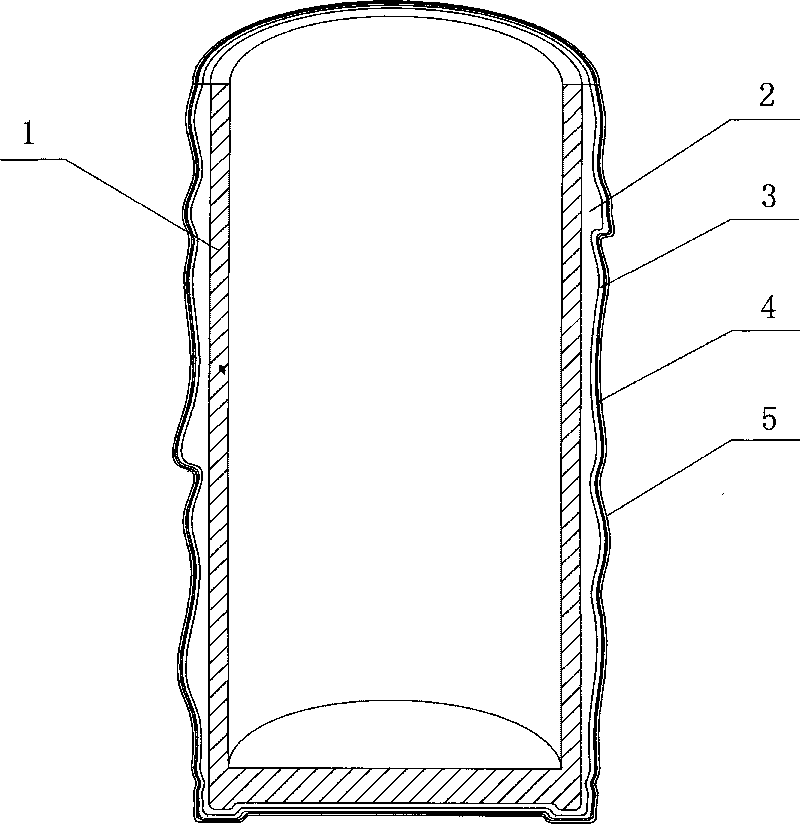

[0027] As shown in the figure, a metal three-dimensional craft product is composed of a carrier layer, an epoxy coating layer, a metal layer, a decoration layer and a protective layer. The carrier layer is attached with a layer made of crystal epoxy molding material with a three-dimensional pattern The epoxy coating layer, a metal layer is electroformed on the epoxy coating layer, and a decorative layer made of gold or silver is attached to the metal layer. The decorative layer is coated with a protective layer, carrier layer, and epoxy coating layer , The metal layer, the decoration layer and the protective layer are solidly integrated.

[0028] When attaching the epoxy coating layer to the carrier, use the previously made silica gel film, put the silica gel film on the carrier, and pour crystal epoxy molding material between the silica gel film and the carrier, because the silica gel film can be made by embossing method. After solidifying for 2-8 hours and uncovering the film, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com