Method for preparing tardocillin

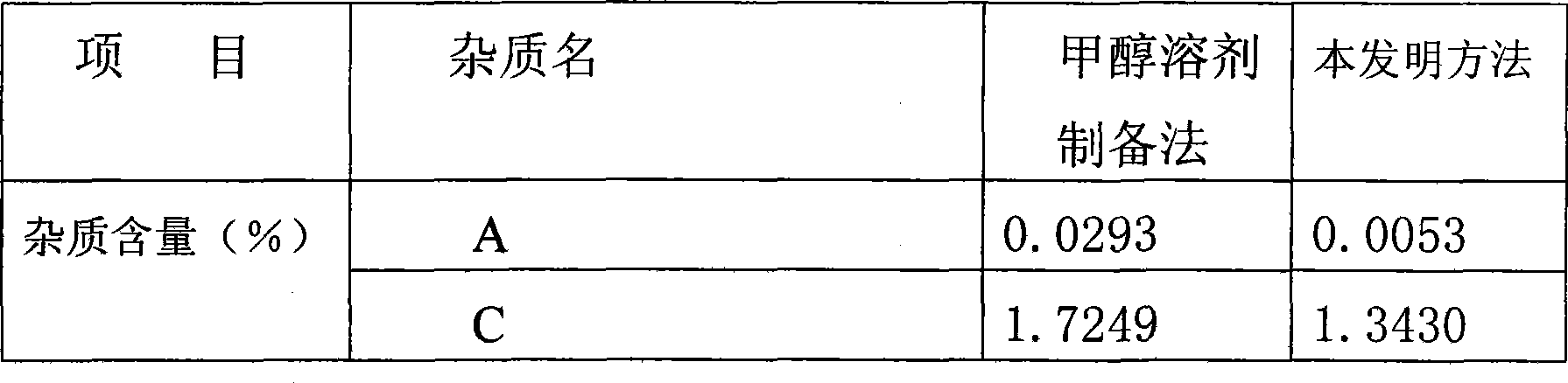

A technology of benzathine penicillin and dibenzylethylenediamine is applied in the production and preparation field of benzathine penicillin, and can solve the problems of increased manufacturing cost, small crystal particle size, difficult control of reaction speed, etc., and achieves improved yield, reduced toxicity, The effect of improving product quality and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] At room temperature, add 40g of DBED to 350ml of ethanol with an alcohol concentration of 66% to make solution A; add 81g of penicillin G potassium to 1000ml of ethanol with an alcohol concentration of 66% to make solution B, and adjust the pH value of the solution to 6.2-6.8 . Start stirring and adjust it to 100r / min, add 4.5ml of A solution to B solution in advance, and continue to add the remaining A solution to B solution at a speed of 5L1 / min to obtain a suspension of benzathine penicillin, after suction filtration The filter cake was washed twice with 200ml of water and 95% ethyl acetate solution, and vacuum-dried for 120 minutes to obtain benzathine penicillin dry powder with a particle size of 100%≤80 μm.

Embodiment 2

[0026] At room temperature, add 50Kg DBED to 340L of 60% ethanol, press it into the DBED metering tank through pre-filtration and sterilizing filtration; Sterilize and filter and press into the crystallization tank. Start stirring and adjust it to 150r / min, add 3.6L of DBED solution to the crystallization tank in advance, and add the remaining DBED solution to the penicillin G sodium solution at a speed of 10L / min to obtain a suspension of sterile benzathine penicillin liquid, the filter cake obtained by suction filtration was washed twice with 200L water for injection and 150L 95% ethyl acetate solution, and dried in vacuum for 240 minutes to obtain sterile benzathine penicillin dry powder, which was mixed to obtain sterile benzathine penicillin powder, and then packed to obtain the finished product , particle size 100% ≤ 60μm.

example example 3

[0028] At room temperature, add 40Kg DBED to 50% ethanol to adjust to 400L, and press it into the DBED metering tank through pre-filtration and sterilizing filtration; Filtration and sterile filtration are pressed into the crystallization tank. Start the stirring and adjust it to 200r / min, add 3.2L of DBED solution in advance to the crystallization tank, and continue to add the remaining DBED solution to the penicillin G potassium solution at a speed of 15L / min to obtain a mixture of sterile benzathine penicillin. Suspension, the filter cake obtained by suction filtration was washed twice with 200L water for injection and 150L 95% ethyl acetate respectively, and vacuum-dried for 240 minutes to obtain sterile benzathine penicillin dry powder, which was subpackaged to obtain finished products with a particle size of 100%≤30 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com