Phosphates adhesive and preparation method thereof

A phosphate and adhesive technology, applied in adhesives, inorganic adhesives, etc., can solve the problems of high temperature resistance and water resistance of phosphate adhesives, and achieve the effects of small thermal expansion coefficient, high strength, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

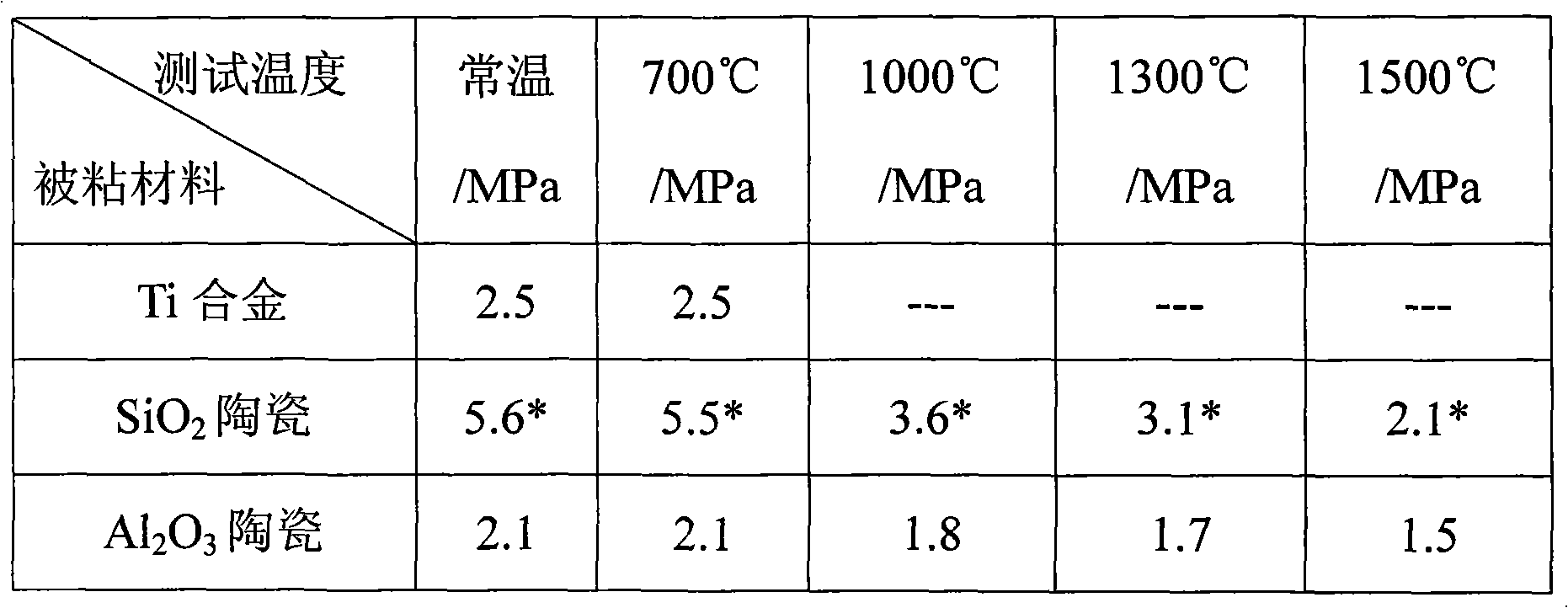

Examples

specific Embodiment approach 1

[0009] Embodiment 1: The phosphate adhesive in this embodiment consists of 100 parts by mass of phosphoric acid solution, 20 to 50 parts of aluminum hydroxide powder, 50 to 100 parts of alumina powder, and 1 to 20 parts of zirconia powder It is made with 1-20 parts of zinc oxide powder or aluminum nitride powder; the mass concentration of phosphoric acid solution is 80%-90%.

specific Embodiment approach 2

[0010] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the phosphate adhesive consists of 100 parts by mass of phosphoric acid solution, 30-40 parts of aluminum hydroxide powder, 60-90 parts of aluminum oxide powder, It is prepared by 4-15 parts of zirconia powder and 4-15 parts of zinc oxide powder or aluminum nitride powder. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0011] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the phosphate adhesive consists of 100 parts of phosphoric acid solution, 35 parts of aluminum hydroxide powder, 75 parts of aluminum oxide powder, and 10 parts of oxidized Zirconium powder is made with 10 parts of zinc oxide powder or aluminum nitride powder. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com