MEMS encapsulation method

A technology for sealing packaging and devices, which is applied in the direction of precision positioning equipment, microstructure devices, and processing microstructure devices, etc. It can solve the problems of reducing the strength of the packaging structure, increasing the parasitic effect, and limiting the thickness of the device structure, so as to improve the strength and sealing Performance, benefits of integrated manufacturing, wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

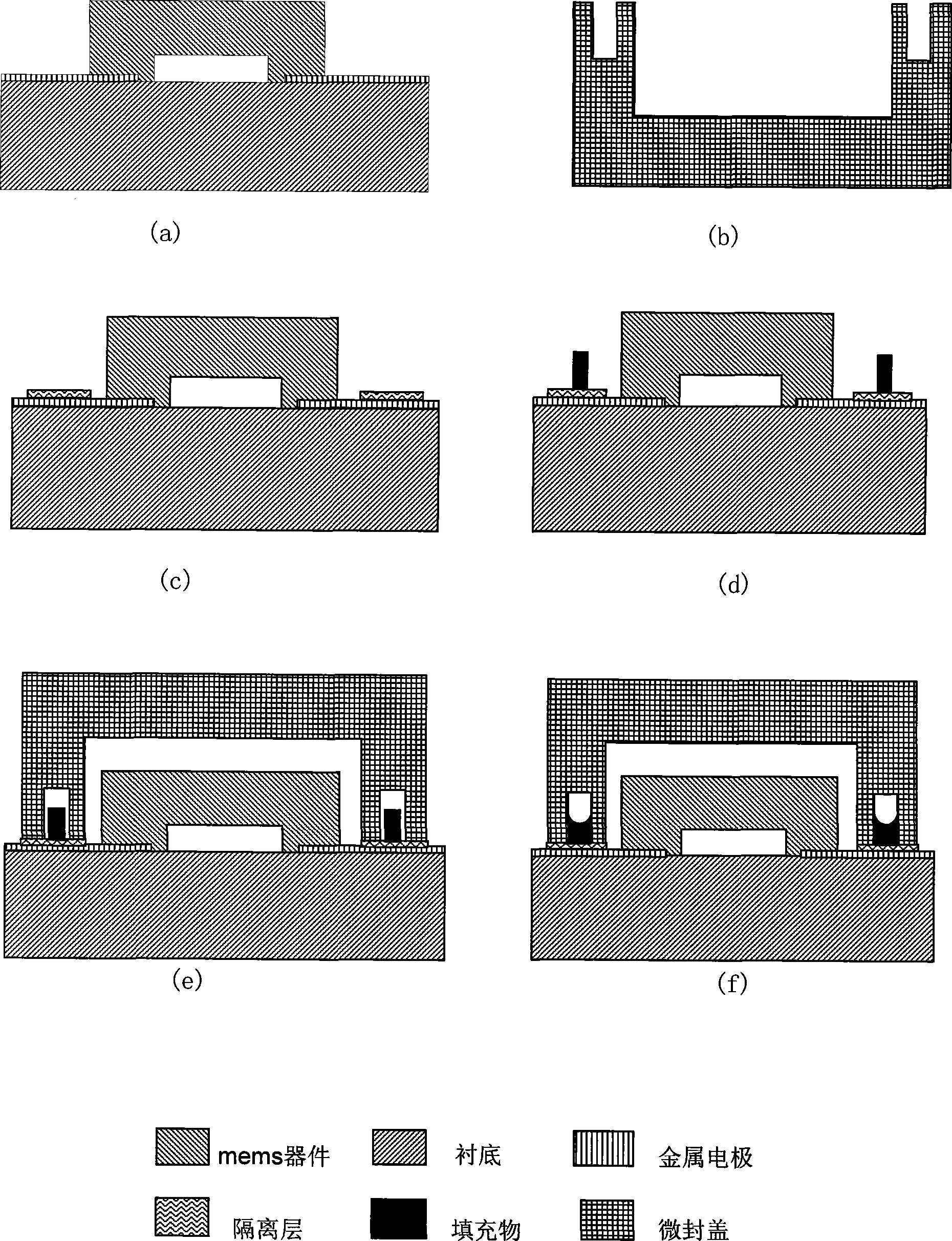

[0028] Combine below figure 1 The present invention is described in further detail with specific embodiment:

[0029] Step 1, prepare the micro-capping: etch a micro-capping structure with a bottom opening that matches the MEMS device on a glass sheet or a silicon wafer, and etch a groove at the bottom of the micro-capping wall, etch The process is ICP or RIE method.

[0030] Step 2. Prepare the isolation layer: use chemical vapor deposition, sputtering and other methods to prepare SiO on the electrodes around the MEMS device 2 or Si 3 N 4 An isolation layer located in the area where the microcap will be hermetically bonded to the substrate.

[0031] Step 3. Preparation of fillers: Prepare patterned fillers on the isolation layer by chemical vapor deposition, sputtering, evaporation, screen printing, spin coating, spraying, etc. The filler materials are tin, indium and its alloys, glass etc., requiring its melting point to be lower than 450 degrees.

[0032] Step 4. Bond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com