Visible light InGaN based photoelectrochemical cell and preparation

A photoelectrochemical cell and visible light technology, applied in the field of visible light responsive photoelectrochemical cells and preparation, can solve problems such as difficulty in the preparation of group III nitride photoelectrodes, and achieve the effects of good stability and high conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

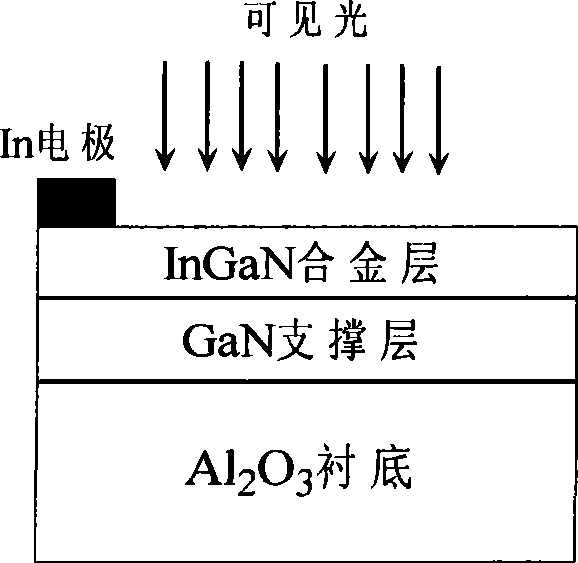

[0017] InGaN alloy growth structure and photoelectrode structure such as figure 1 shown. The substrate is made of 2 inch α-Al 2 o 3 (0001), the GaN support layer was grown by a two-step method with a thickness of 1 to 2 μm. After the GaN growth is completed, the temperature of the reaction chamber is lowered to the InGaN growth temperature, and TMIn and TMGa are introduced as Group III reaction sources, N 2 As carrier gas, NH 3 As the reaction source of group V, the growth of InGaN alloy starts, In x Ga 1-x The growth temperature range of the N alloy layer is from 600 to 850°C, which determines the composition of In in the InGaN alloy, and the thickness is from 50nm to 500nm. All samples are undoped.

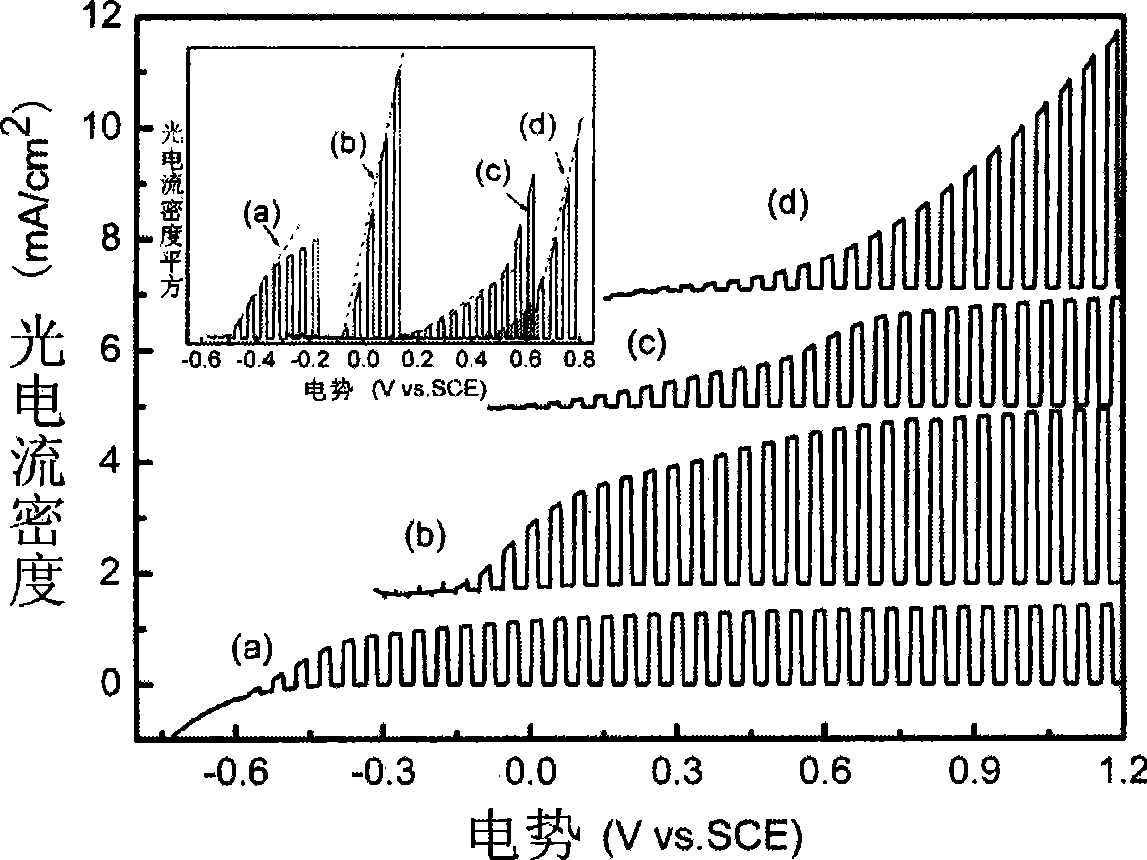

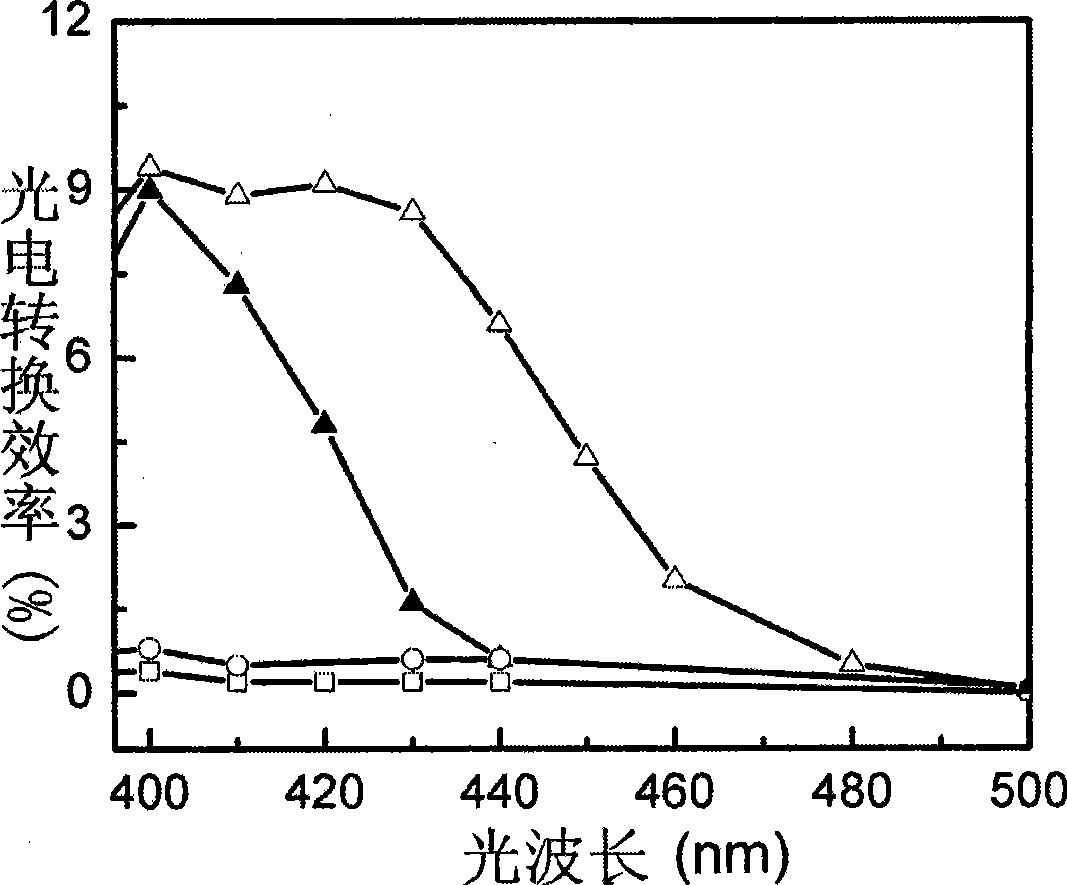

[0018] The photoelectrode structure of the photoelectrochemical cell is as figure 1As shown, the In composition x of InGaN alloy is respectively 0, 0.06, 0.12, and 0.2 to prepare photoelectrodes. By means of sputtering, metal In is deposited on the surface of the InGaN f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com