Ultraviolet irradiation device

A technology for irradiation devices and ultraviolet rays, which is applied in the direction of lighting devices, damage prevention measures for lighting devices, lighting and heating equipment, etc., and can solve problems such as a large amount of nitrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

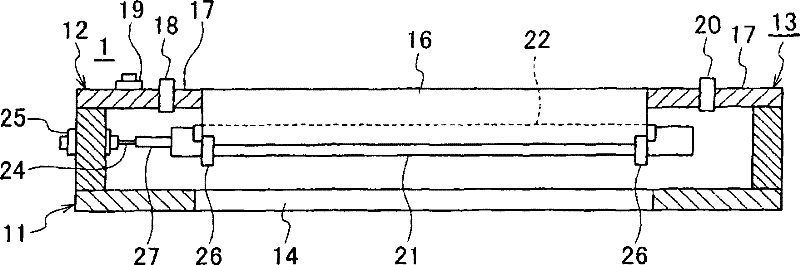

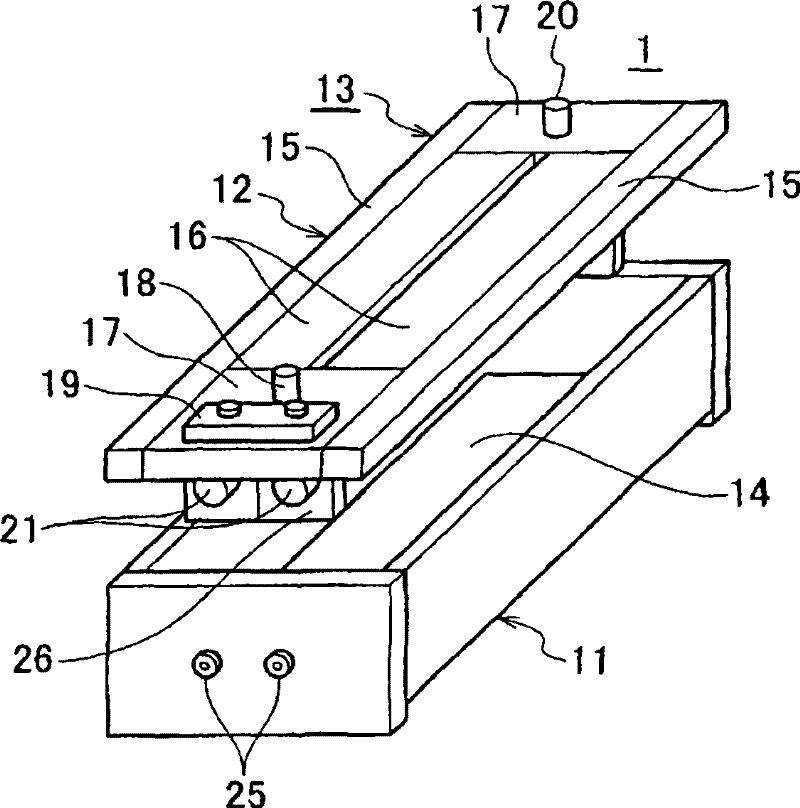

[0034] Such as figure 1 , figure 2 As shown, the ultraviolet irradiation device 1 of the present embodiment includes a lamp housing 13 composed of a frame body 11 and a cover body 12 with an open upper surface. Almost the entire lower surface of the lamp housing 13 serves as an irradiation window, and an ultraviolet transmission window member 14 is attached to the irradiation window portion.

[0035] The cover 12 of the lamp housing 13 is composed of side members 15 on both sides, an external electrode block 16 constituting a cooling material and external electrode constituting member, and a low-voltage terminal block 17 . One low-voltage terminal block 17 is provided with a nitrogen inflow port 18 and a low-voltage terminal block 19 , and the other low-voltage terminal block 17 is provided with a nitrogen outflow port 20 .

[0036] In this embodiment, the lamp housing 13 accommodates two dielectric barrier discharge lamps 21 each equipped with an outer electrode block 16 ....

no. 2 approach

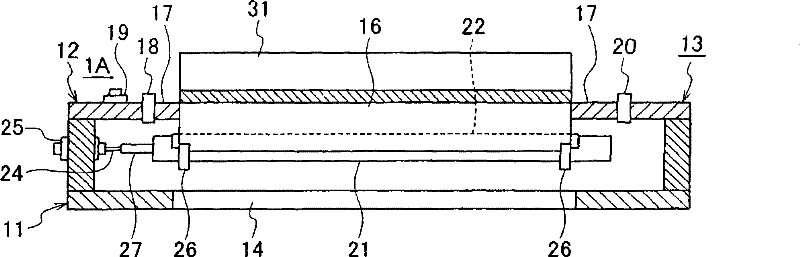

[0042] image 3 The ultraviolet irradiation apparatus 1A which concerns on 2nd Embodiment of this invention is shown. The ultraviolet irradiation device 1A of this embodiment is relative to figure 1 , figure 2The ultraviolet irradiation device 1 of the first embodiment shown in , is characterized in that a heat sink block 31 of a heat sink structure is provided in close contact with the outer surface of the external electrode block 16 forming a part of the cover body 12 of the lamp housing 13 . For example, the heat dissipation block 31 is fixed to the outer surface of the external electrode block 16 with an adhesive (hatched portion in the figure) made of a silicon member for heat dissipation.

[0043] And, in image 3 In the second embodiment shown in , the same reference numerals are used to indicate the figure 1 , figure 2 The constituent elements are the same as those of the first embodiment shown in FIG.

[0044] According to this embodiment, by arranging the hea...

no. 3 approach

[0046] Figure 4 , Figure 5 The ultraviolet irradiation apparatus 1B which concerns on 3rd Embodiment of this invention is shown. The ultraviolet irradiation device 1B of this embodiment is relative to figure 1 , figure 2 The first embodiment shown in FIG. 1 is characterized in that each external electrode block 16A prepared according to the number of lamps constituting the cover body 12 has a heat sink structure. That is, the grooved groove 22 is formed on the lower surface of the external electrode block 16A so as to be in close contact with the upper half peripheral surface of the dielectric barrier discharge lamp 21, and the heat sink 41 is formed on the upper surface of the external electrode block 16A. As in the first and second embodiments, the outer electrode block 16A that is in close contact with the dielectric barrier discharge lamp 21 is made of aluminum or stainless steel, which is a conductive material excellent in thermal conductivity. And, in Figure 4 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com