Injectable water-proof calcium phosphate bone cement

A technology of calcium phosphate bone cement and tricalcium phosphate, applied in medical science, prosthesis, etc., can solve the problems of syringe injection, cracking, bone cement dispersion, etc., to avoid joint stiffness, relieve pain, and reduce dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

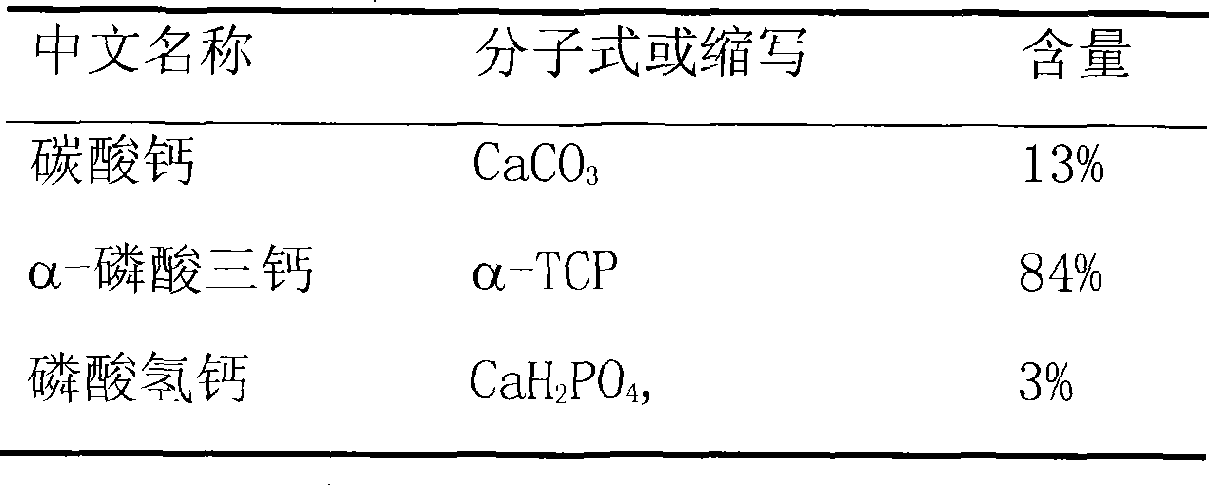

[0006] ICPC consists of two parts, solid phase and liquid phase, and the specific components are shown in the table below:

[0007] Solid phase component

[0008]

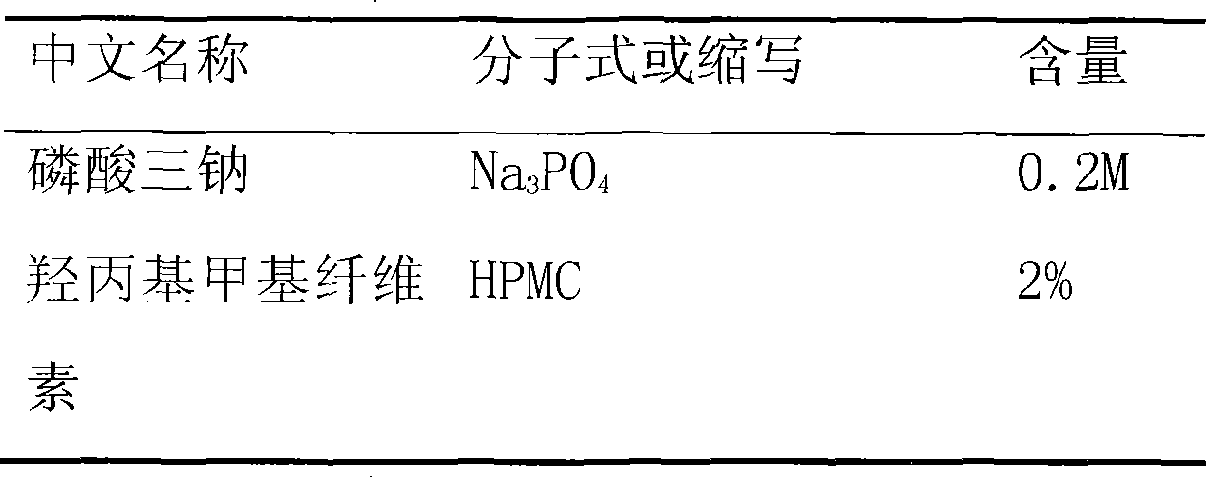

[0009] liquid components

[0010]

[0011] After mixing the solid phase and the liquid phase at a ratio of 1g / 0.4ml, the calcium carbonate, α-tricalcium phosphate, and calcium hydrogen phosphate in the solid phase dissolve and precipitate chemically with the trisodium phosphate in the liquid phase, and finally produce hydroxyl phosphorus gray stone. The hydroxypropyl methylcellulose in the liquid phase component does not participate in the curing reaction, and has the effect of improving the cement injection performance and waterproof performance during the curing reaction. After mixing the solid and liquid phases of the cement, it should be quickly moved to the syringe, and then injected into the affected area through the corresponding injection needle. During this period, the cement can be shaped arbitrar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com