High-efficiency hollow grid shaped spherical suspending filling material

A suspension packing and grid-like technology, which is applied in the field of high-efficiency hollow grid-shaped spherical suspension packing, can solve the problems of partial surface area waste of packing, less biofilm amount, and insufficient film thickness, etc., and achieve fast film formation and large biofilm amount , the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

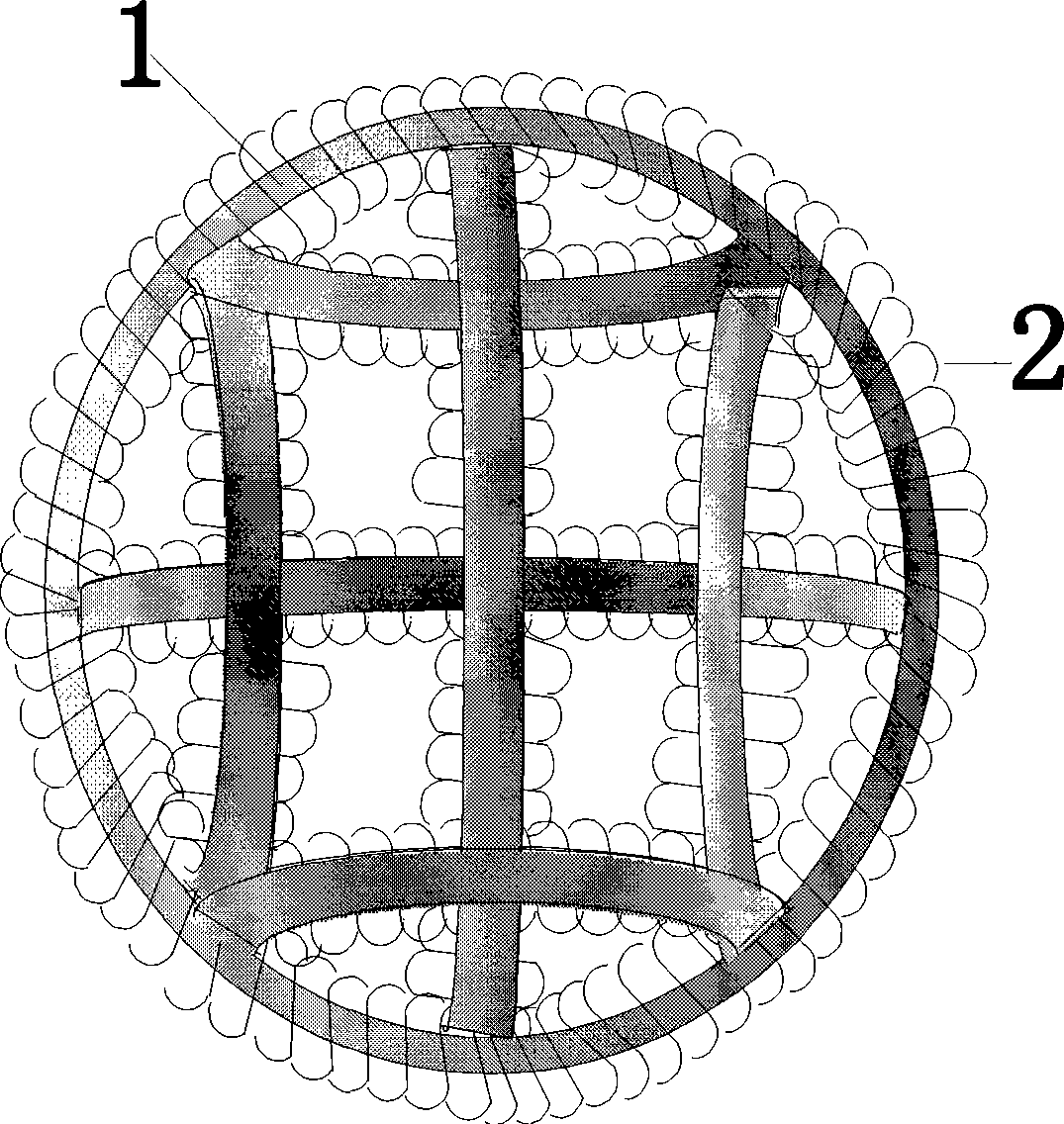

[0014] like figure 1 As shown, a high-efficiency hollow grid-shaped spherical suspension filler is composed of hollow grid spherical plastic 1 and soft rough fiber filaments 2. The hollow grid spherical plastic 1 is a hollow grid-shaped spherical plastic. The nature of the soft rough fiber filament 2 is a soft rough fiber filament, and the soft rough fiber filament 2 is wound on the hollow mesh spherical plastic 1 .

Embodiment 2

[0016] This filler overcomes the shortcomings of other rigid fillers that are difficult to hang film, less film amount and small thickness, and a large number of biofilms can be attached to the rough fiber filaments on the surface of the hollow grid-shaped spherical plastic, which increases the volume load of the reactor. The filler is turned up and down together with the water flow and gas in the reactor, and the sewage and gas can fully contact with the sludge attached to the rough fiber filaments, which can increase the removal of organic matter in the sewage due to the presence of a large number of microorganisms while increasing the oxygen benefit rate efficiency.

Embodiment 3

[0018] During the transfer of oxygen from the surface of the filler to the interior, the microorganisms on the hollow mesh-shaped spherical inner fiber filaments are at a disadvantage in the competition for oxygen. Oxygen is first absorbed and utilized by the microorganisms on the outer fiber filaments, so the inner fiber filaments The microorganisms on the surface gradually become anaerobic due to the reduction of oxygen. Moreover, because the thickness of the biofilm attached to the soft rough fiber by this filler is relatively large, the utilization of oxygen by microorganisms in the vertical direction is also in a gradient shape. oxygen state. The function of short-term nitrification and denitrification can be realized under the condition that the anaerobic and aerobic sludge exist at the same time, and the NH 3 The removal of -N has a very good effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com