Interference type integral photo-signal modulator and preparation thereof

An integrated, optical signal technology, applied in light guides, optics, instruments, etc., can solve the problems of polarization state control, electrode packaging difficulties, and inability to achieve stable modulation, and achieve the effect of simple structure and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

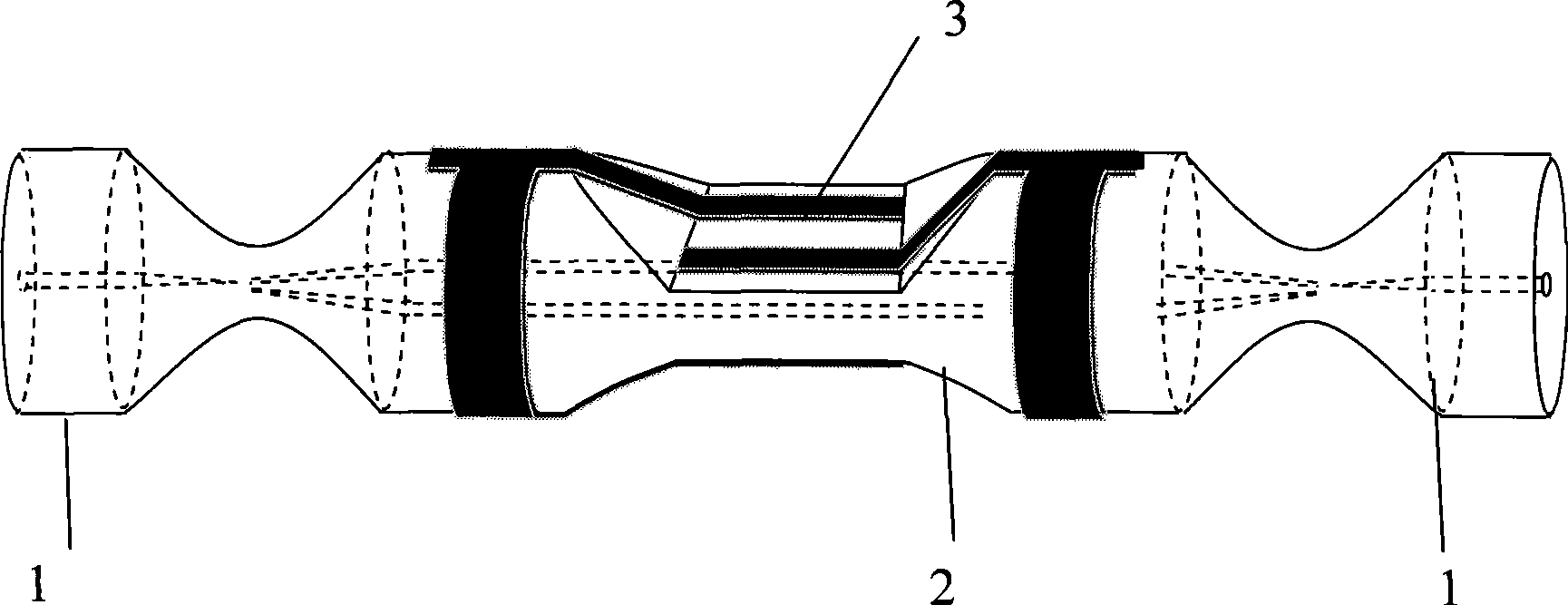

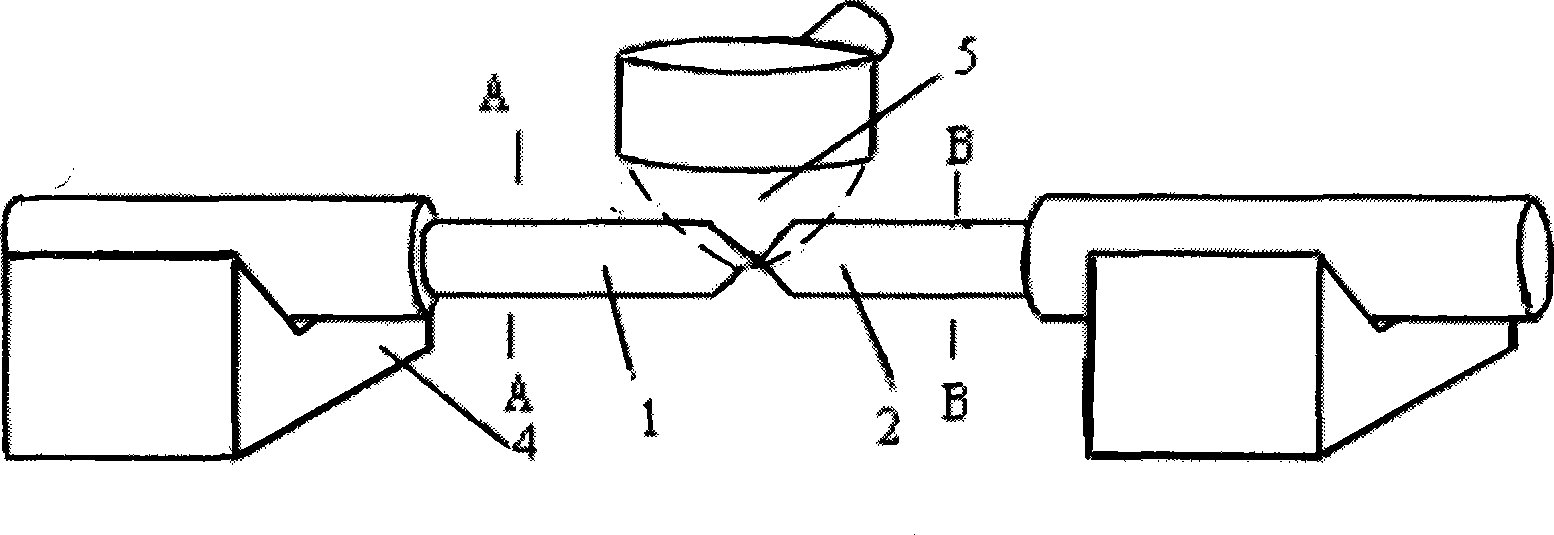

[0058] Specific Embodiment 1: Fabricate an interference-type integrated optical signal modulator by thermal polarization method and ultraviolet laser micromachining.

[0059] Proceed as follows:

[0060] 1. Take two sections of standard single-mode optical fiber 1 respectively, use optical fiber strippers to strip the coating layer of the optical fiber for about 30mm, clean the optical fiber cladding with a mixture of alcohol and ether, and cut the end face of the optical fiber flat with an optical fiber cutter. Clean the fiber cladding again.

[0061] 2. Take a section of double-core optical fiber 2 with a length of 400mm, and use optical fiber strippers to strip the coating layer of the optical fiber for about 30mm, clean the optical fiber cladding with a mixture of alcohol and ether, and use an optical fiber cutter to clean the two end faces of the optical fiber. Cut flat, and clean the fiber cladding again.

[0062] 3. Solder the two ends of the standard single-mode opti...

specific Embodiment approach 2

[0072] Specific embodiment 2, using the ultraviolet polarization method and ultraviolet laser micromachining to fabricate an interference type integrated optical signal modulator.

[0073] Proceed as follows:

[0074] 1. Take two sections of standard single-mode optical fiber 1 respectively, use optical fiber strippers to strip the coating layer of the optical fiber for about 30mm, clean the optical fiber cladding with a mixture of alcohol and ether, and cut the end face of the optical fiber flat with an optical fiber cutter. Clean the fiber cladding again.

[0075] 2. Take a section of double-core optical fiber 2 with a length of 400mm, and use optical fiber strippers to strip the coating layer of the optical fiber for about 30mm, clean the optical fiber cladding with a mixture of alcohol and ether, and use an optical fiber cutter to clean the two end faces of the optical fiber. Cut flat, and clean the fiber cladding again.

[0076] 3. Solder the two ends of the standard si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com