Heat pipe type transformer tube

A transformer bushing and heat pipe type technology, which is applied to transformer/inductor parts, transformer/inductor coils/windings/connections, electrical components, etc., can solve the problem of unstable electrical performance, heavy maintenance workload, and short service life and other problems, to achieve the effect of increasing the reliability and service life of the work, good cooling effect and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

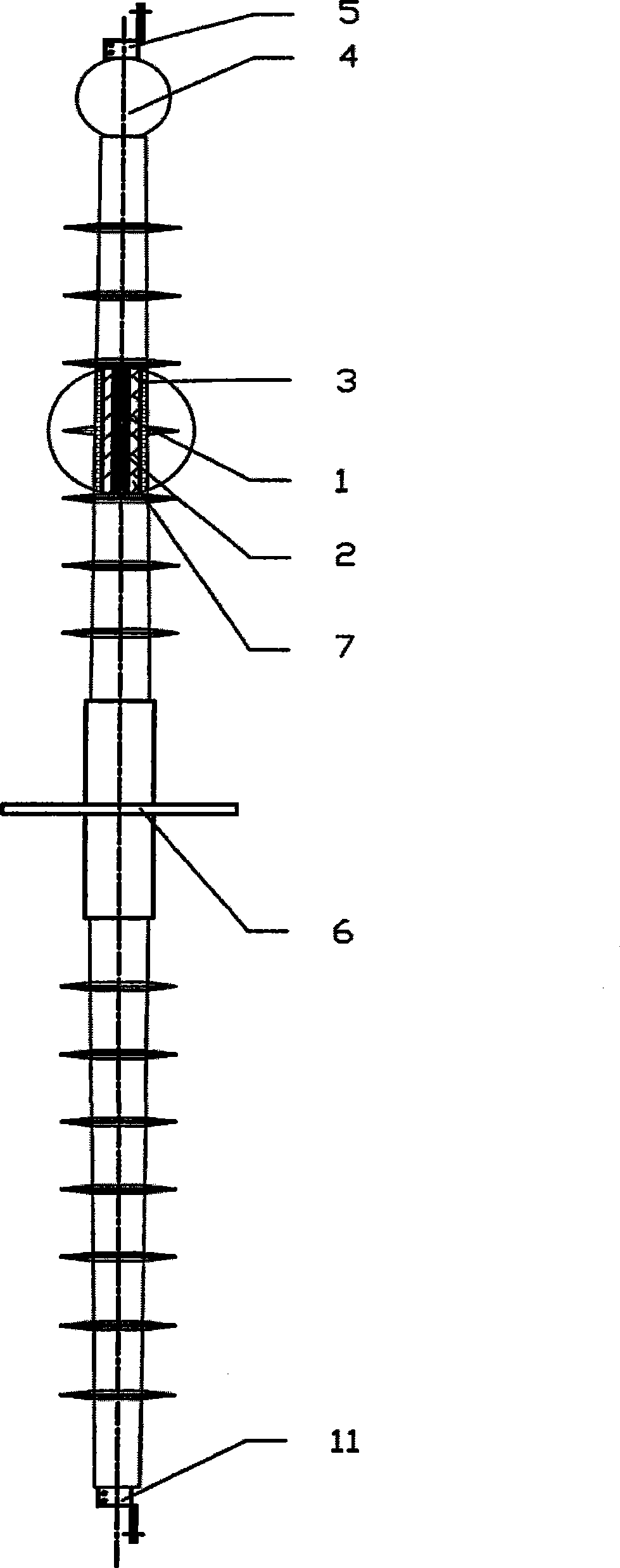

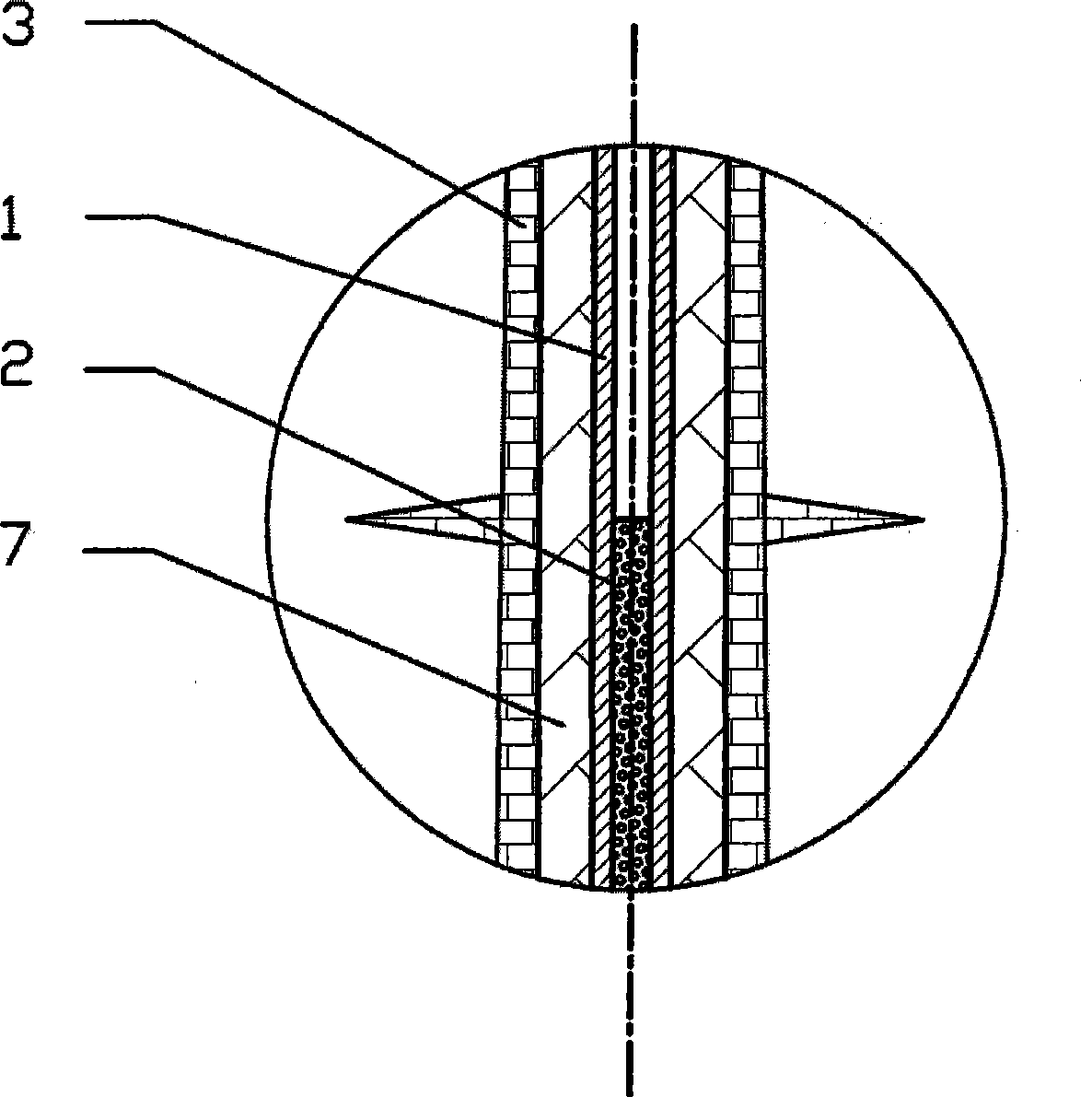

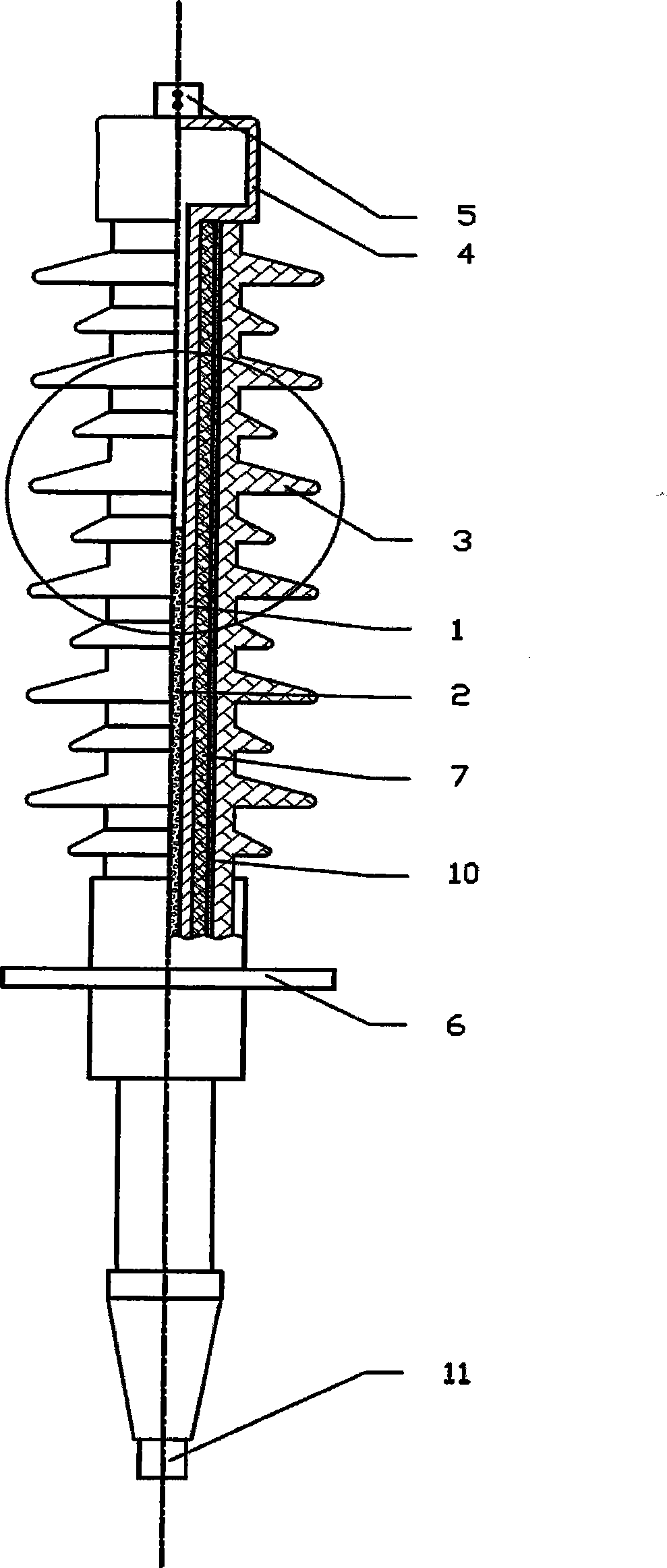

[0025] One of the specific embodiments of the present invention is a heat pipe dry sleeve. Such as Figure 1a As shown, the conductive tube 1 is a hollow metal tube, one end is connected to the terminal 2 11; connected. The outer insulation and connection structure of conductive pipe 1 are similar to those of ordinary dry-type high-voltage bushings, such as Figure 1b As shown, the main insulation layer 7 is wound on the outside of the conductive pipe 1, and the insulation jacket 3 and the connecting flange 6 are set on the outside of the main insulation layer 7. The main insulation layer 7 is generally made of resin-impregnated glass fiber or polytetrafluoroethylene and capacitor voltage equalizing electrodes. The capacitor core is formed by winding boards, the insulating jacket 3 is generally made of silicon rubber material, and the main in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com