Salient pole wound rotor asynchronous motor

A technology for asynchronous motors and wound rotors, which is applied in the manufacture of stator/rotor bodies, windings, electric components, etc., can solve the problems of complex electromagnetic action mechanism, achieve high rotor winding utilization, improve waveform and three-phase symmetry, The effect of reducing radial size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

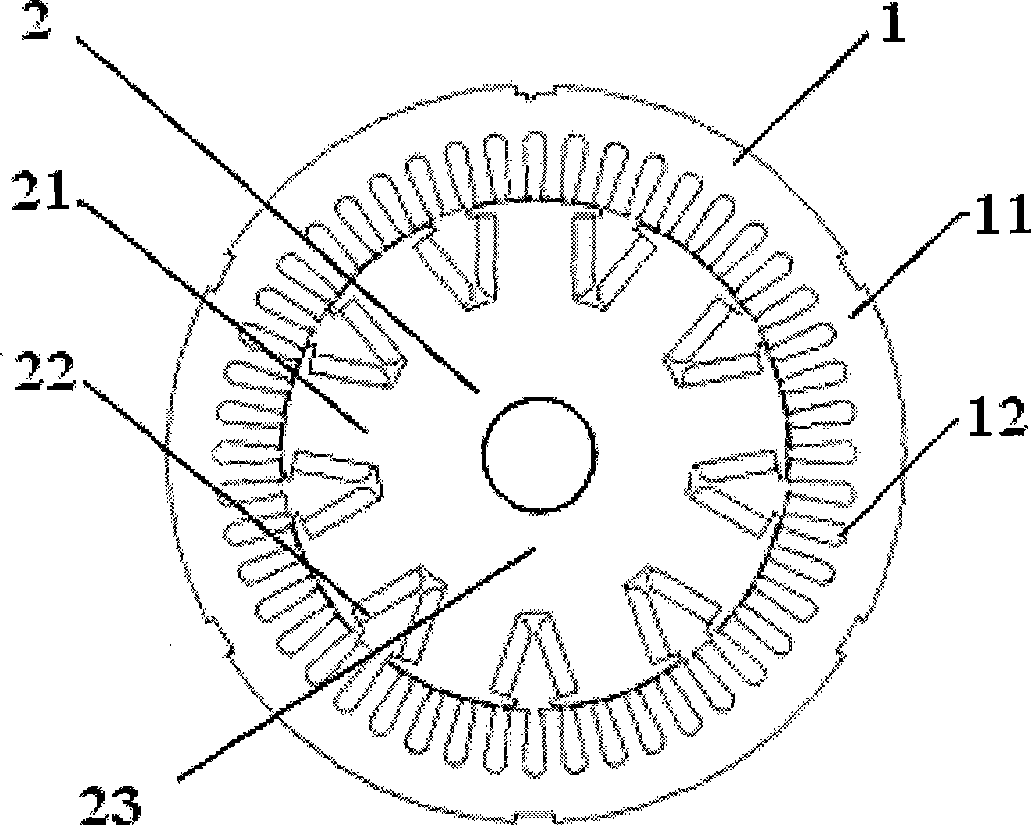

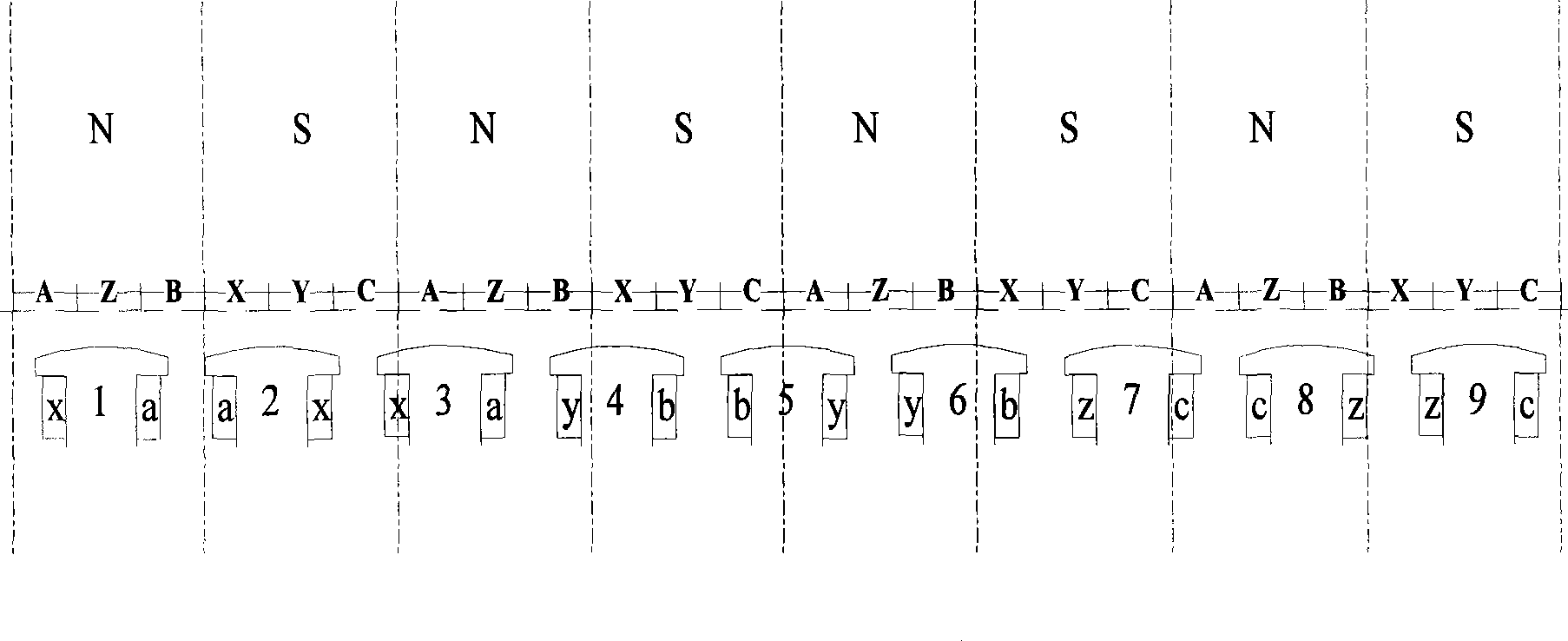

[0022] Such as figure 2 As shown, the present invention includes two main parts of a stator 1 and a rotor 2 . The stator 1 has the same structure as the stator of an ordinary AC motor. The stator core 11 made of slotted silicon steel sheets and the number of phases embedded in the core slots are m 1 , the stator windings 12 with the number of pole pairs P are jointly formed. The rotor 2 is similar to the rotor structure of a common salient pole synchronous motor, and the number of salient poles on the rotor 2 is n p , n p A convex magnetic pole 21 is evenly distributed on the circumference of the back yoke 22, and the convex magnetic pole 21 is covered with an AC coil 23, but the damping winding in the conventional synchronous motor rotor is canceled on the rotor magnetic pole.

[0023] The number of salient poles on the salient pole rotor n p satisfy:

[0024] 2Pp <4P (1)

[0025] That is, the number of salient poles n p More than the number of magnetic field poles, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com