Intelligent high-frequency induction heating equipment

A high-frequency induction heating, intelligent technology, applied in induction heating, induction heating control, lighting and heating equipment, etc., can solve the problems of increased components, difficult to promote, high price, achieve the same volume, facilitate promotion, and cost less. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

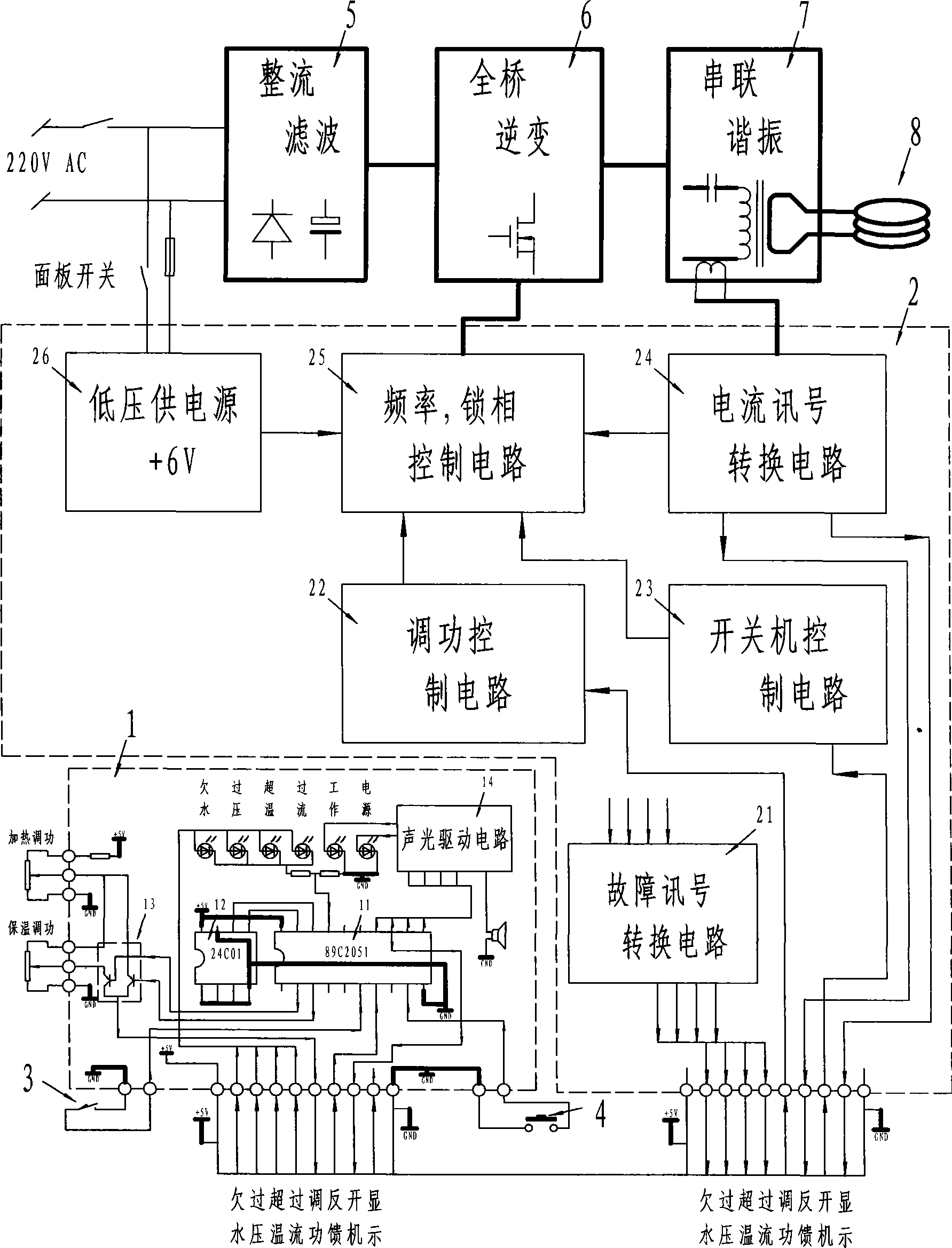

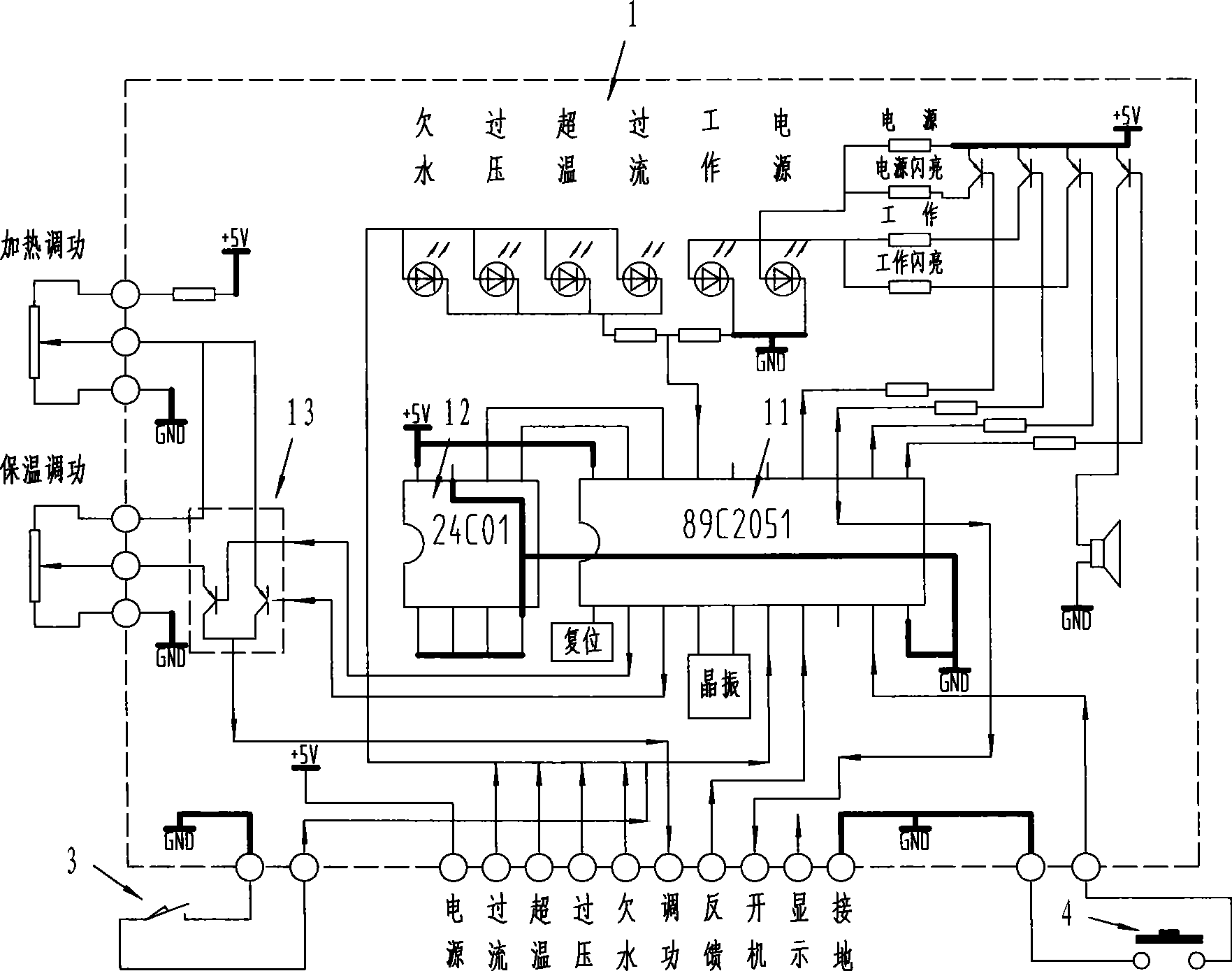

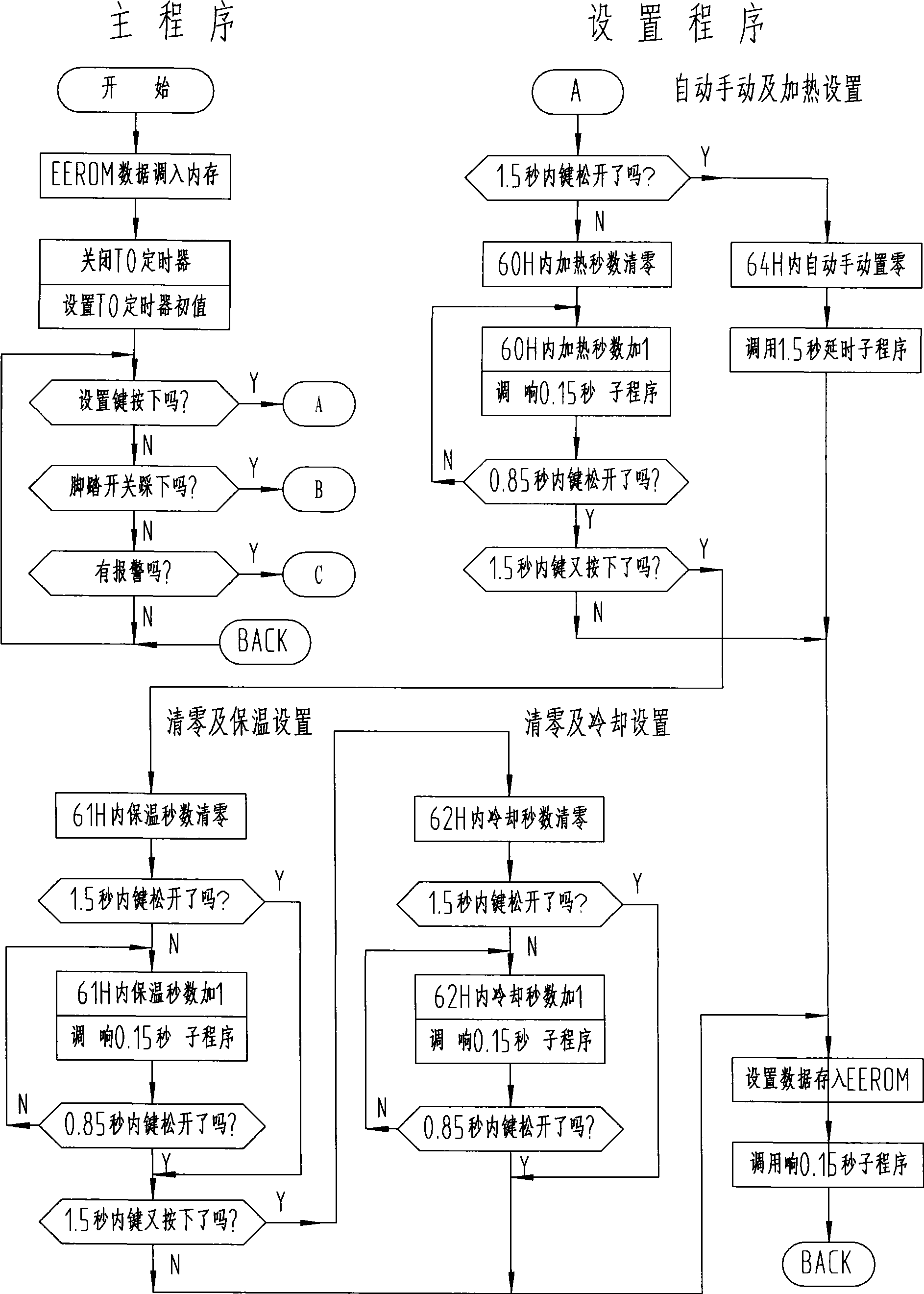

[0034] see figure 1 , 2 , the present invention mainly includes a single-chip microcomputer control circuit 1, a main control board 2, a foot switch 3, a setting key 4, a rectification filter 5, a full-bridge inverter 6, a series resonance 7 and an induction coil 8. The main control board 2 mainly includes a fault signal conversion circuit 21 , a power regulation control circuit 22 , a switch control circuit 23 , a current signal conversion circuit 24 , a frequency and phase-lock control circuit 25 and a low-voltage power supply 26 . The single-chip microcomputer control circuit 1 mainly includes a single-chip microcomputer 11 , an EEROM memory 12 , a heating and heat preservation conversion circuit 13 and an acousto-optic drive circuit 14 . The model adopted by the single-chip microcomputer 11 is 89C2051, and the model adopted by the memory 12 is 24C01. The main control board 2 is controlled by a single-chip microcomputer 11 . The conversion of the function of the single-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com