Method and apparatus for removing polymer volatile component

A devolatilization device and polymer technology, applied in separation methods, chemical instruments and methods, liquid degassing, etc., can solve problems such as insufficient volatile efficiency, affecting devolatilization efficiency, short fluid path, etc., and achieve balance and stability Good performance, improved devolatilization efficiency, and short residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

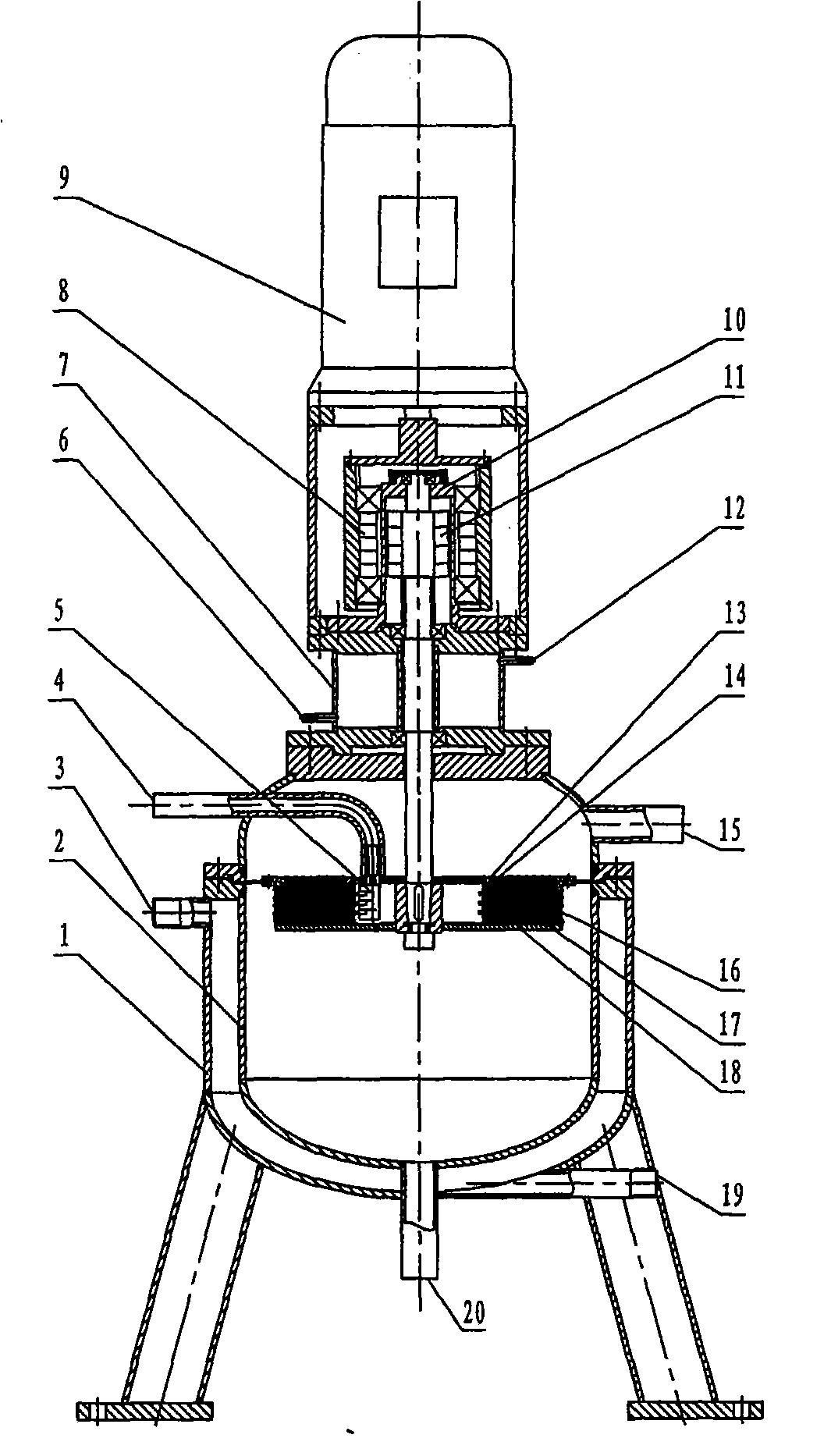

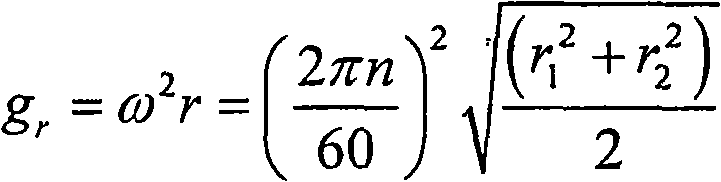

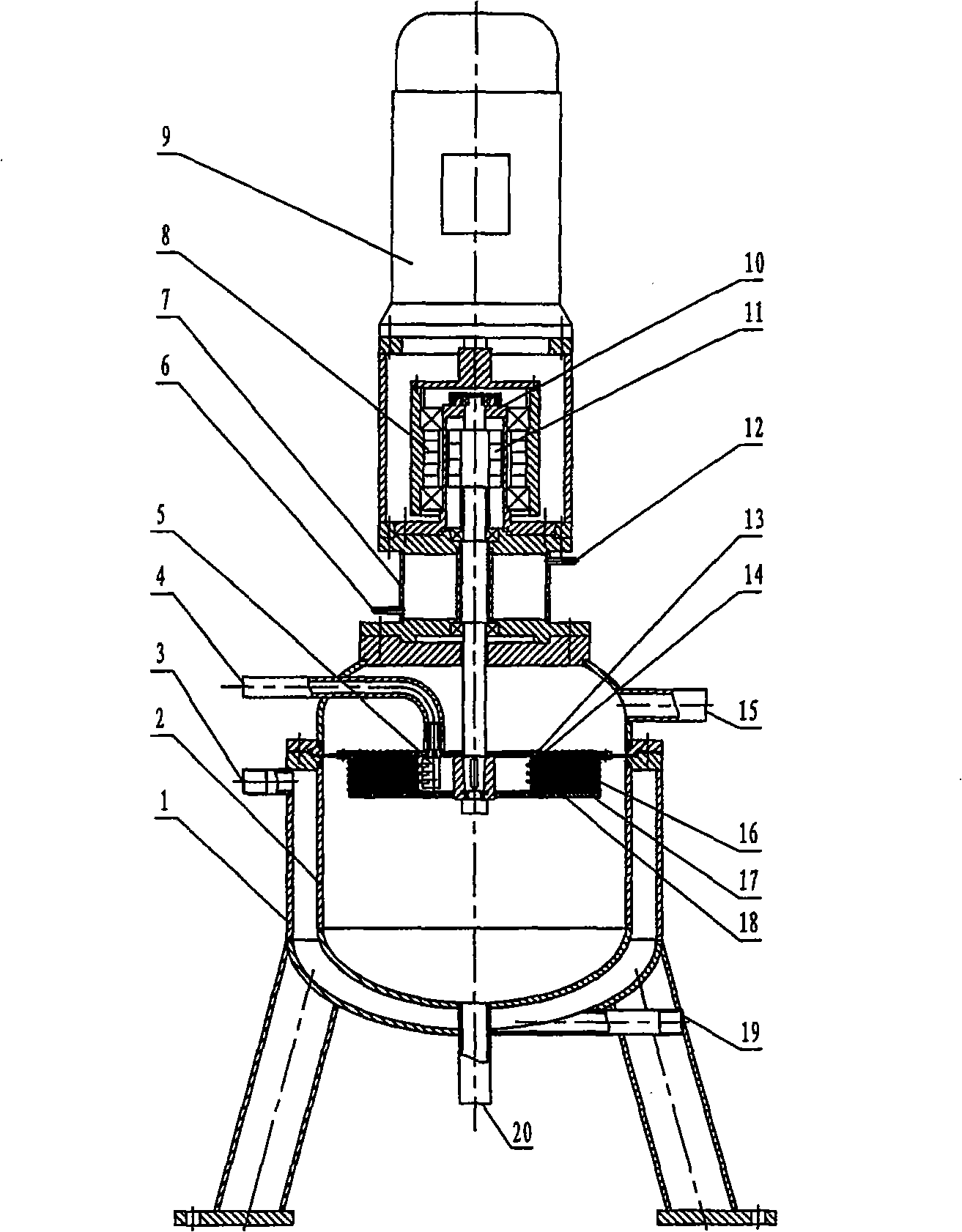

[0040] Adopt the supergravity devolatilization device of the present invention to carry out primary devolatilization to the acrylonitrile polymer, first open the vacuum system connected with the supergravity devolatilization device, make the vacuum degree in the supergravity devolatilization device reach 755mmHg, and heat the material to 66-68°C, the material delivery pipe is sent to the supergravity devolatilization equipment at the same temperature, and the material is evenly distributed in the three liquid receiving rings along the full height direction of the packing of the rotor through the distributor. Grid type-outward inclined type-grid type are regularly arranged, adjust the speed of the rotor to make the equipment operate under the condition of 184g of supergravity, complete the first-level devolatilization process of acrylonitrile polymers, and analyze the materials before and after treatment. Nitrile content decreased from 0.71 wt% to 0.071 wt%.

Embodiment 2

[0042] The above-mentioned high-gravity devolatilization device of the present invention is used to carry out secondary devolatilization of acrylonitrile polymers, and the process flow is shown in FIG. 8 . First, open the vacuum system connected to the supergravity devolatilization device, so that the vacuum degree in each stage of the supergravity devolatilization device reaches 755mmHg, heat the material to 66-68°C, and send it into the first stage through the material delivery pipe. The temperature is 66-68 In the high-gravity devolatilization equipment at ℃, the material is evenly distributed in the two liquid receiving rings along the packing height direction of the rotor through the distributor, and the packing is arranged according to the law of inner slope-grid type-outer slope-grid type-law , adjust the rotating speed of the rotor to make the equipment operate under the condition of 184g supergravity, and complete the primary devolatilization process of the acrylonitri...

Embodiment 3

[0044] The above-mentioned high-gravity devolatilization device of the present invention is used to carry out primary devolatilization of acrylonitrile-based polymers, the operation steps and other conditions are the same as in Example 1, and the filling is in accordance with the rule of inner oblique type-hollow cavity-outer oblique type-hollow cavity Arrangement, analysis of the material before and after devolatilization treatment, the content of acrylonitrile decreased from 0.71wt% to 0.082wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com