Vegetable washer

A vegetable washing machine and inner barrel technology, which is used in household appliances, food processing, food science, etc., can solve problems such as water leakage, wasted water, and short circuits, and achieve the effect of reducing production costs, enhancing cleaning strength, and reducing sealing requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

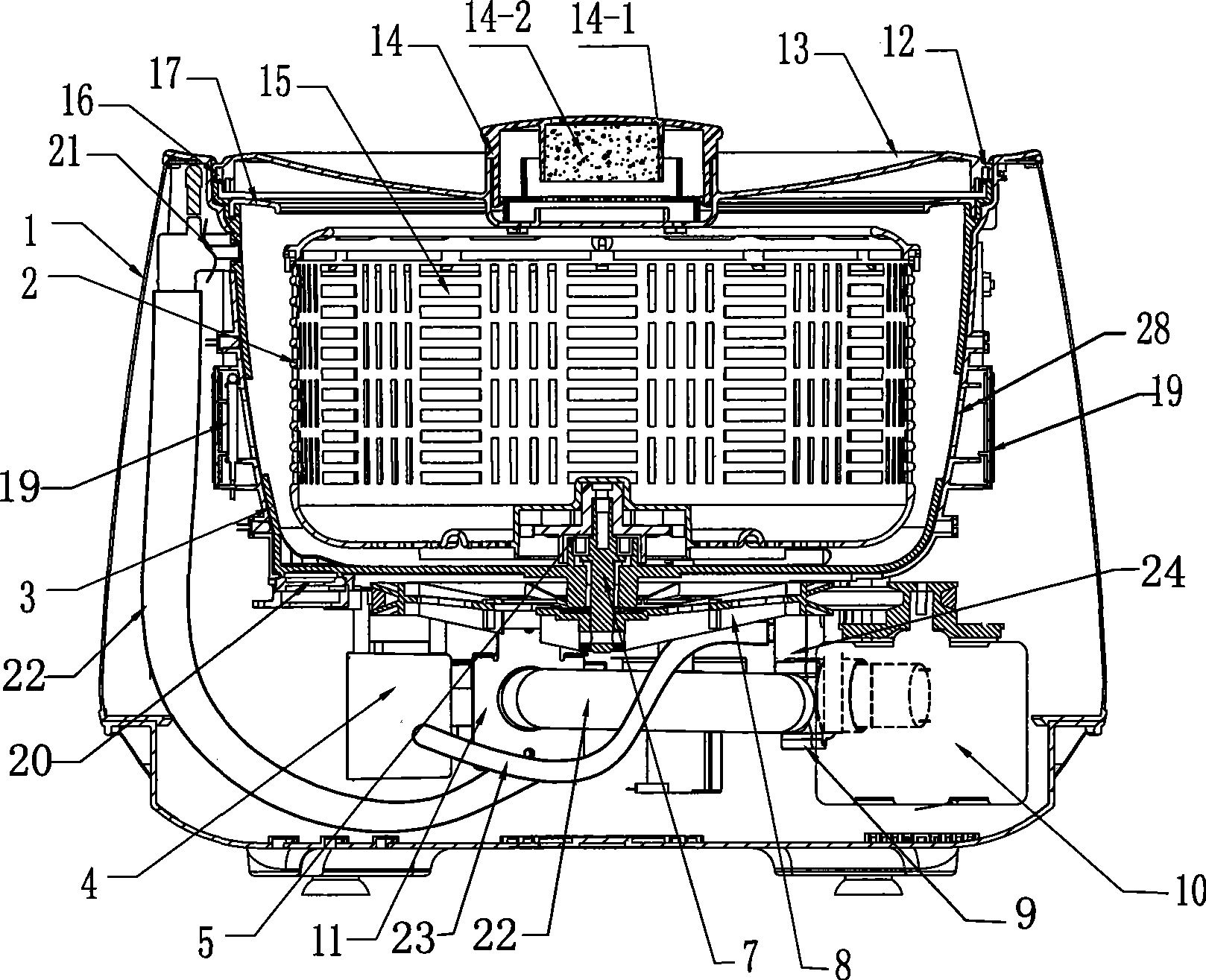

[0018] Embodiment 1, as figure 1 As shown, a vegetable washing machine includes a housing 1, a driving device 10 located in the housing 1, an outer barrel 3 and an inner barrel 2, wherein the inner barrel 2 is concentrically set in the outer barrel 3, and the wall of the inner barrel 2 is provided with a water-permeable hole 15 , the driving device 10 is a motor, the center of the bottom of the outer barrel 3 is vertically equipped with a transmission shaft 7, and the center of the bottom of the inner barrel 2 is provided with a connecting piece 5 that is detachably connected to the upper end of the drive shaft 7, and the inner barrel 2 does not work in the vegetable washing machine. The lower end of the transmission shaft 7 is connected to the motor 10 through the pulley 8, the upper edge of the inner barrel 2 is lower than the upper edge of the outer barrel 3, and the water retaining ring 17 is arranged on the inner wall of the outer barrel 3 higher than the upper edge of the...

Embodiment 2

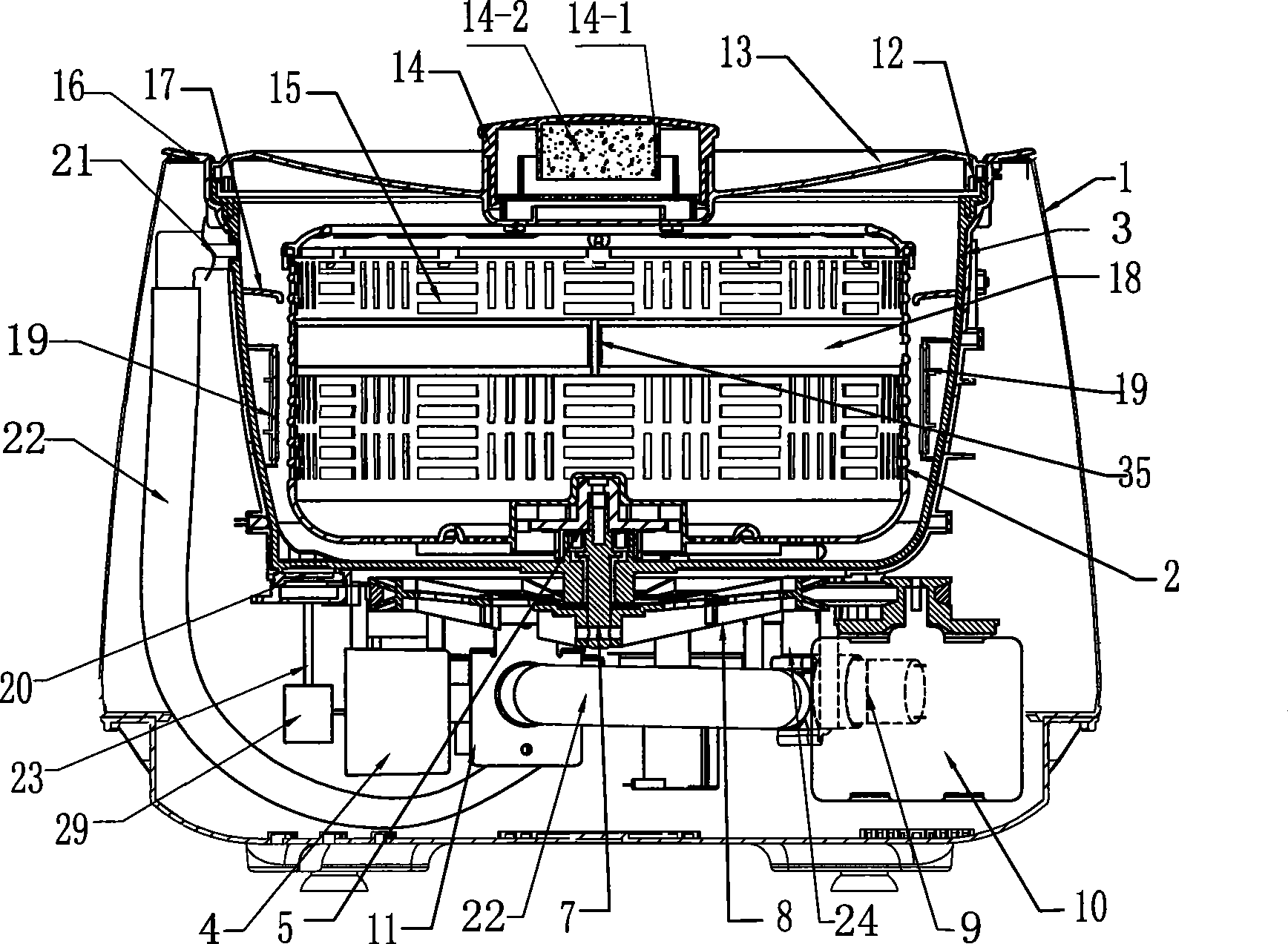

[0019] Embodiment 2, as figure 2As shown, the water retaining ring 17 is arranged on the upper part of the inner wall of the outer barrel 3, and the wall of the inner barrel 2 corresponding to the water retaining ring 17 is provided with a water flow channel 18 for turning the rotating water flow into the inner barrel, and the water flow channel is along the inner barrel. For the windows 18 set at the same height on the side wall, the height of the windows 18 should be suitable for the passage of water. The number of windows 18 can be set to 2 to 10 according to the size of the windows 18, and there can be more. The side wall of the inner barrel is provided with reinforcing ribs 35; the ultraviolet disinfection device 19 is sealed by a material that can penetrate ultraviolet rays, such as a quartz material, and the sealed ultraviolet disinfection device 19 is assembled on the inner wall of the outer barrel 3; the bottom of the outer barrel 3 is connected by a conduit 23 Ozone...

Embodiment 3

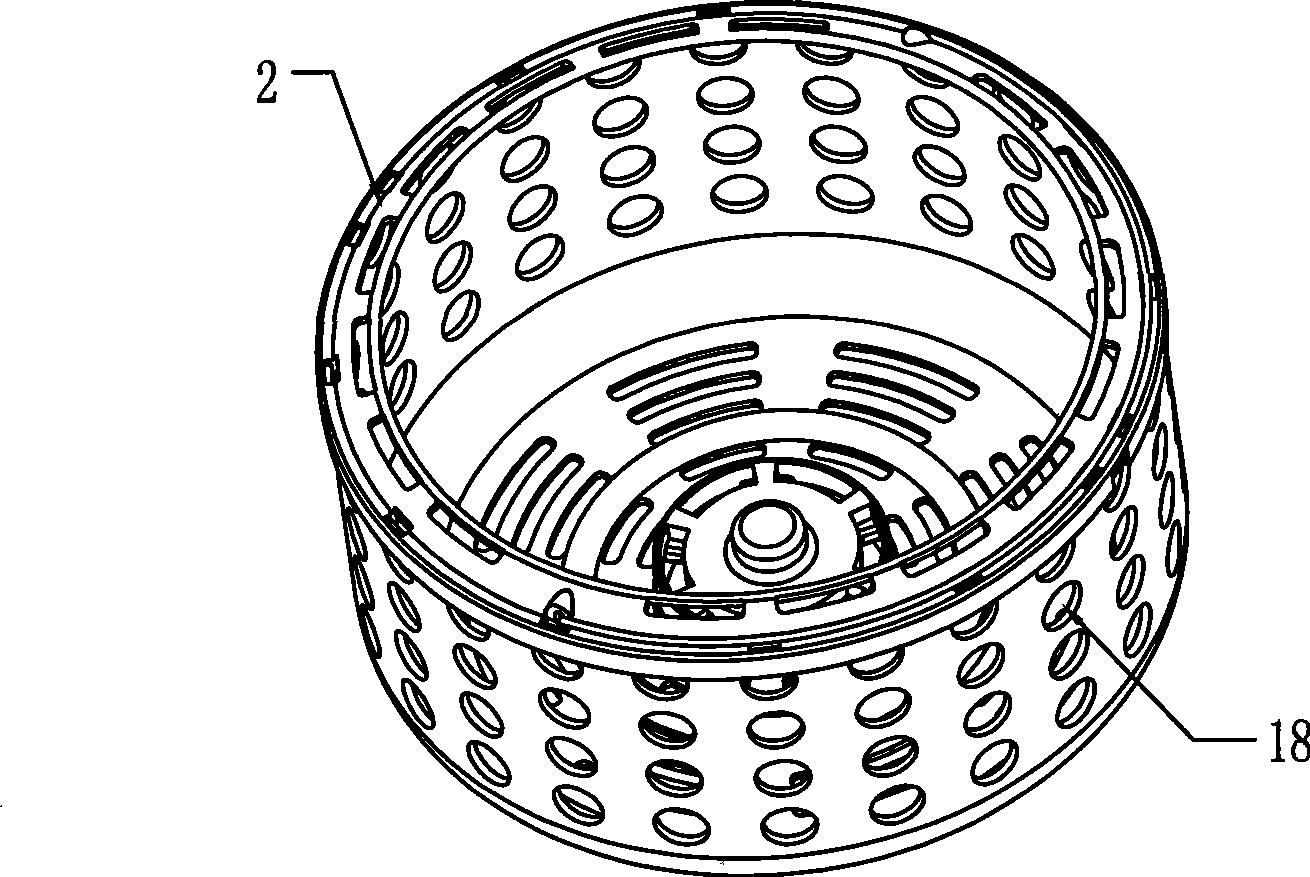

[0020] Embodiment 3, as image 3 Shown is another embodiment of the inner tub. The wall of the inner tub 2 corresponding to the water retaining ring 17 is provided with a water flow channel 18 for turning the rotating water flow into the inner tub. The water flow channel is a circular shape evenly arranged on the inner tub. Through holes 18 are provided with 1 to 5 circles radially along the barrel wall of the inner barrel 2. The diameter of the through holes 18 is not less than 10 mm, and the distance between the through holes 18 is not greater than 5 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com