Method for directly preparing gamma-valerolactone from acetylpropionic acid and aminic acid

A technology of levulinic acid and valerolactone, applied in directions such as organic chemistry, to achieve the effects of simple and convenient operation process, improved environmental friendliness, and avoided energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

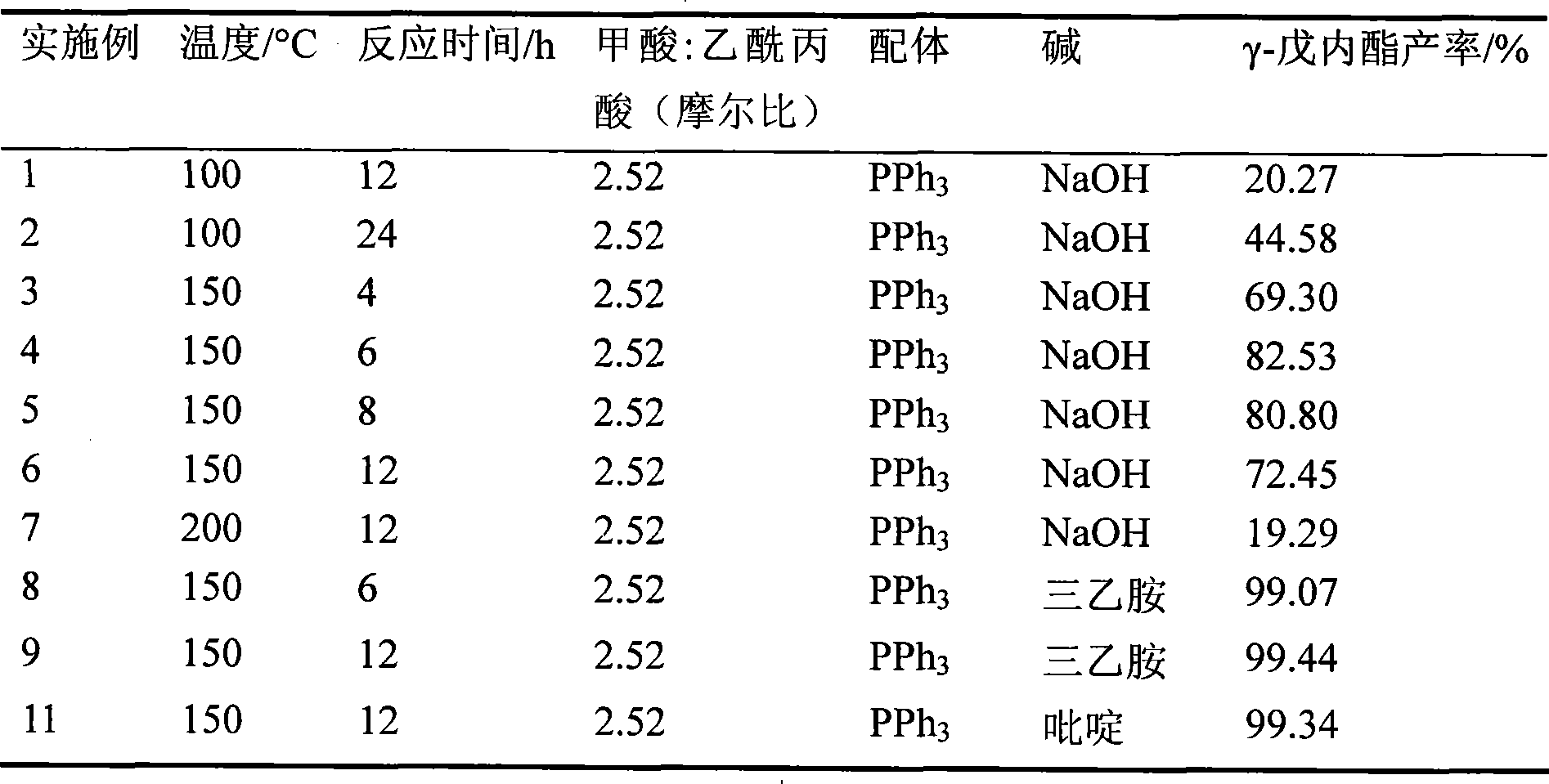

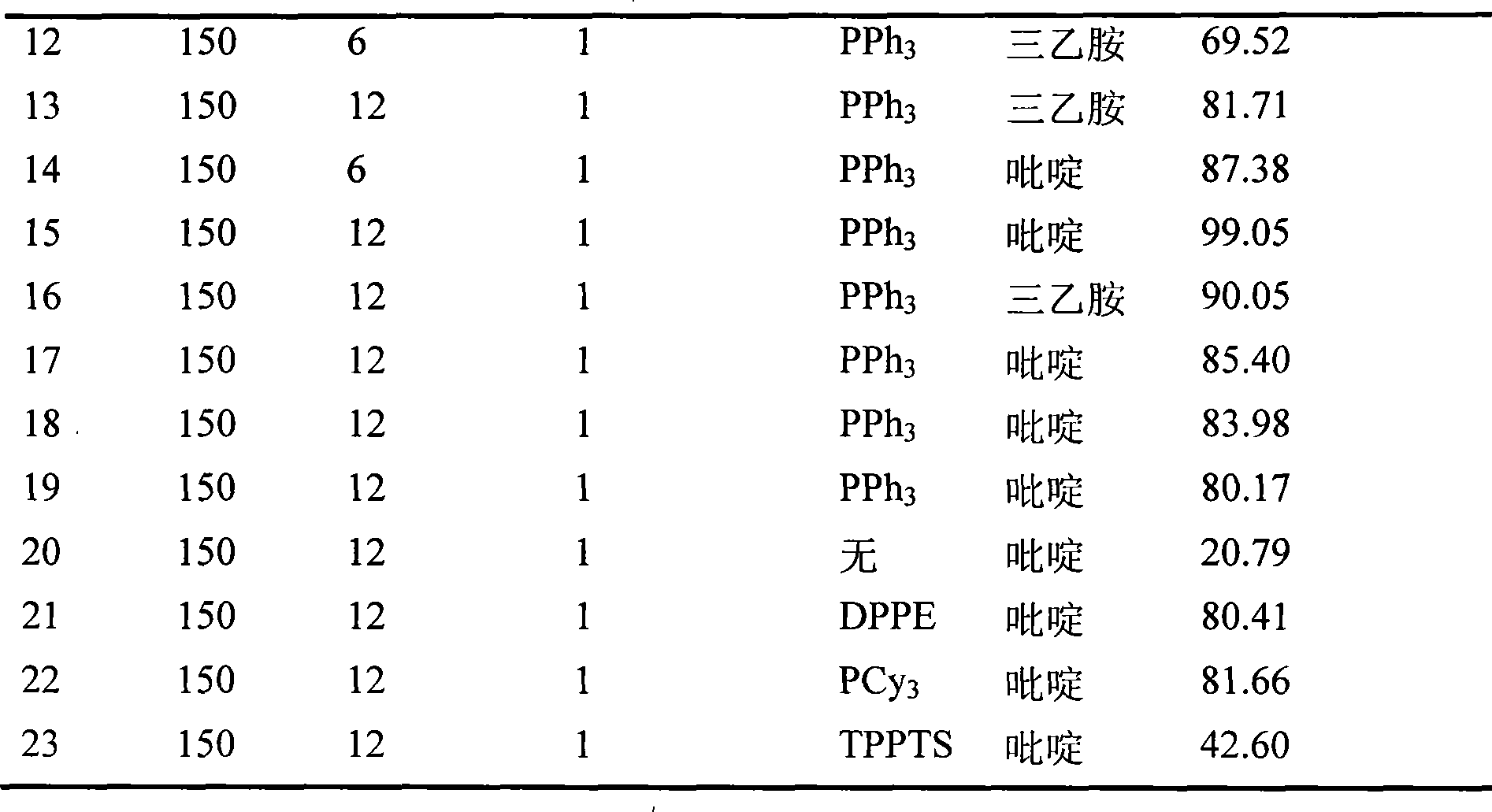

[0025] In the autoclave of 150mL, add 0.2mmol trihydrate ruthenium trichloride, 0.6mmol triphenylphosphine (PPh 3 ), 20mmol sodium hydroxide, 200mmol formic acid and 79.4mmol levulinic acid, sealed and stirred evenly. Heat to 100, 150 or 200°C, keep for 4, 6, 8 or 12 hours, finish the reaction and cool to room temperature, slowly depressurize to atmospheric pressure, open the autoclave, take samples, send to GC-MS for detection, specific experimental temperature, reaction The time and test results are listed in Table 1 with serial numbers 1-7.

Embodiment 8~11

[0027] Add 0.2mmol ruthenium trichloride trihydrate, 0.6mmol triphenylphosphine, 20mmol triethylamine or pyridine, 200mmol formic acid and 79.4mmol levulinic acid into a 150mL autoclave, seal it, and stir well. Heat to 150°C, keep for 6 or 12 hours, finish the reaction and cool to room temperature, slowly depressurize to atmospheric pressure, open the autoclave, take samples at different temperatures and reaction times, send them to GC-MS for detection, and the test results are listed in Table 1 The serial numbers are 8-11.

Embodiment 12~15

[0029] Add 0.2mmol ruthenium trichloride trihydrate, 0.6mmol triphenylphosphine, 20mmol triethylamine or pyridine, 200mmol formic acid and 200mmol levulinic acid into a 150mL autoclave, seal it, and stir well. Heat to 150°C, keep for 6 or 12 hours, finish the reaction, cool to room temperature, slowly depressurize to atmospheric pressure, open the autoclave, take samples, take samples at different temperatures and reaction times, send them to GC-MS for detection, and the test results are listed in the table The serial number in 1 is 12~15.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com