Aqueous resin composition, aqueous coating composition and coating method for plastic molded articles

A water-based resin and water-based paint technology, applied in coatings, latex paints, etc., can solve the problems of coating film hardness, insufficient damage resistance and water resistance, and achieve the effects of excellent adhesion and solvent resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] A four-necked flask equipped with a thermometer, a stirring device, and a reflux condenser was replaced with nitrogen, and "ス-パパ-クロン S-851LS" (manufactured by Nippon Paper Co., Ltd., trade name, maleic anhydride modified chlorinated 100 g of polyolefin) and 190 g of tetrahydrofuran were fully dissolved at 65°C. Next, 40 g of 1-butanol and 3 g of dimethylethanolamine were added thereto, stirred for 15 minutes, and then 300 g of deionized water was added for dispersion. Then, the solvent portion was distilled off under reduced pressure at 65°C to obtain an acid-modified chlorinated polyolefin aqueous dispersion (A-1). The dispersion had a solids concentration of 30% and a pH of 8.1.

[0074] Then, in 133.3 g of the above-mentioned aqueous dispersion (A-1), 131.9 g of deionized water was added under the stirring of the disperser for dilution, and 60 g of the polymerizable monomer mixture (b-1) in the following Table 1 was added and 4 g of "Adeka Liasop SR-1025" (manufact...

Embodiment 2~6

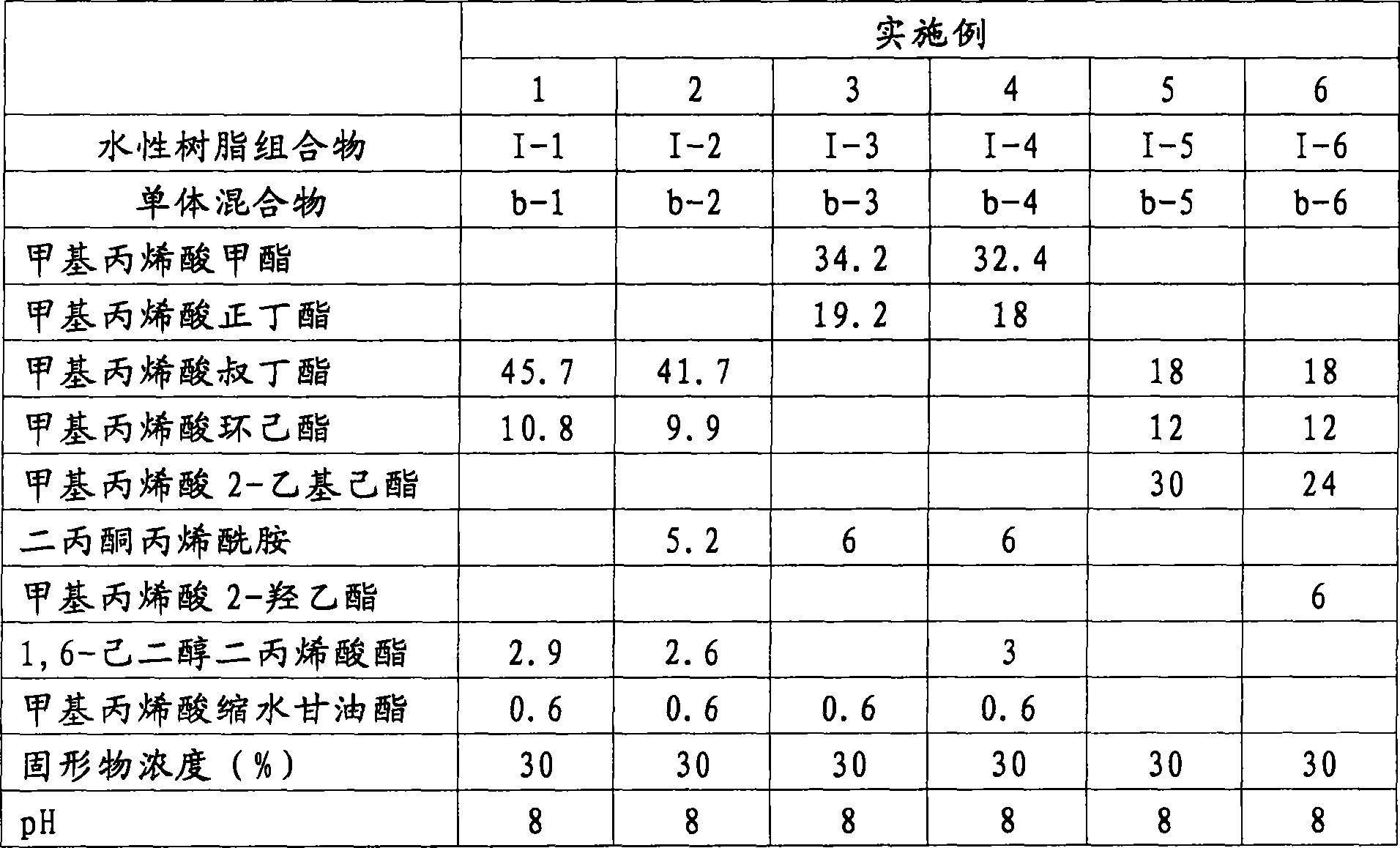

[0076] In Example 1, the proportioning composition of the polymerizable monomer mixture is changed to the composition recorded in Table 1, except that, operate in the same manner as in Example 1 to obtain the water-based resin composition (I-2) ~(I-6).

[0077] Table 1

[0078]

Embodiment 7

[0083] A four-neck flask equipped with a thermometer, a stirring device, and a reflux condenser was replaced with nitrogen, and 100 g of "Su-Pacron S-851LS" and 190 g of tetrahydrofuran were added thereto, and fully dissolved at 65°C. Next, 2.6 g of dibutylamine and 3 g of dimethylethanolamine were added thereto, stirred for 15 minutes, and then 300 g of deionized water was added for dispersion. Then, the solvent was distilled off under reduced pressure at 65°C to obtain an acid-modified chlorinated polyolefin aqueous dispersion (A-3). The dispersion had a solids concentration of 30% and a pH of 8.2.

[0084] Then, 131.9 g of deionized water was added to 133.3 g of the above-mentioned aqueous dispersion (A-3) for dilution under stirring in a disperser, and 60 g of the polymerizable monomer mixture (b-1) of the above-mentioned Table 1 and "Adekaliaso" were added. -プSR-1025" 4g. Transfer it to a four-neck flask equipped with a thermometer, a stirring device, and a reflux conde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com