Sintering gas flue gas sulfuric dioxide decrement discharge technology

A technology of sulfur dioxide and sintering flue gas, which is applied in the field of iron and steel metallurgy, can solve the problems of unsuitable industrial application, high operating cost, and low concentration, achieve broad promotion value and application prospects, reduce investment cost and operating cost, and reduce the total amount The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

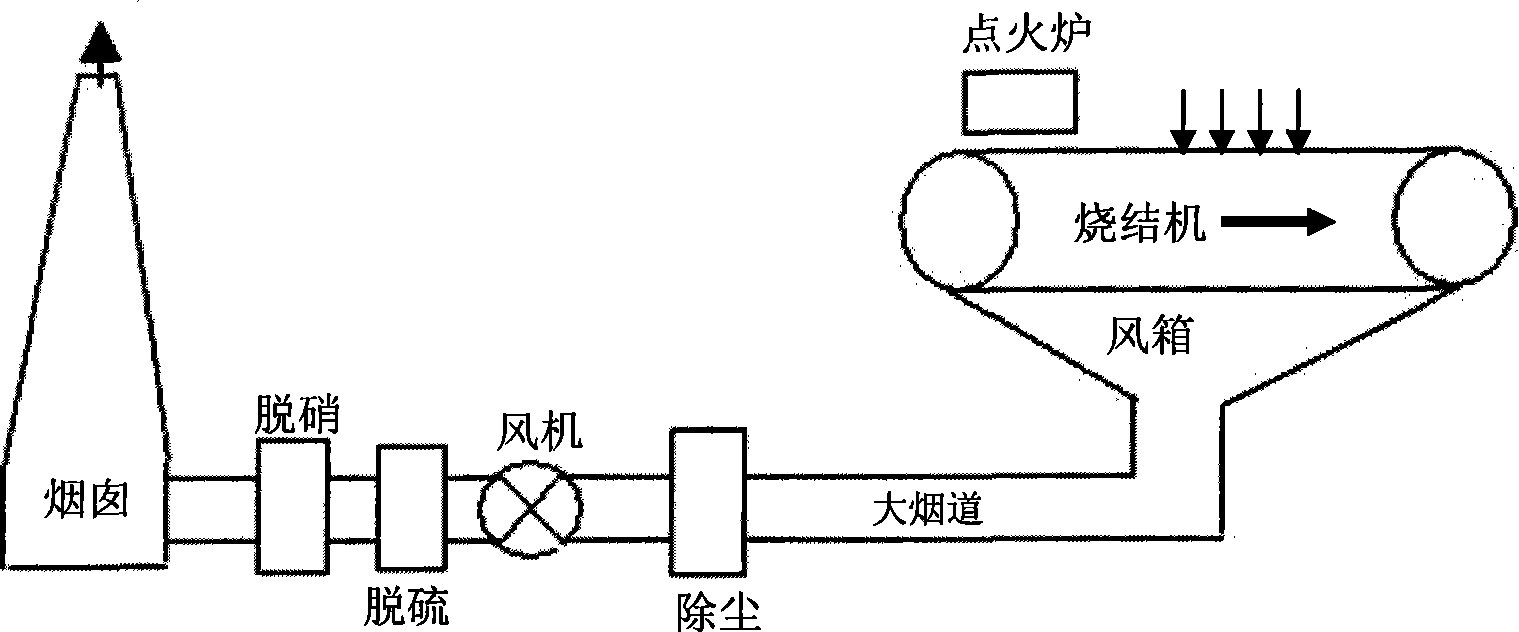

Problems solved by technology

Method used

Image

Examples

Embodiment 1

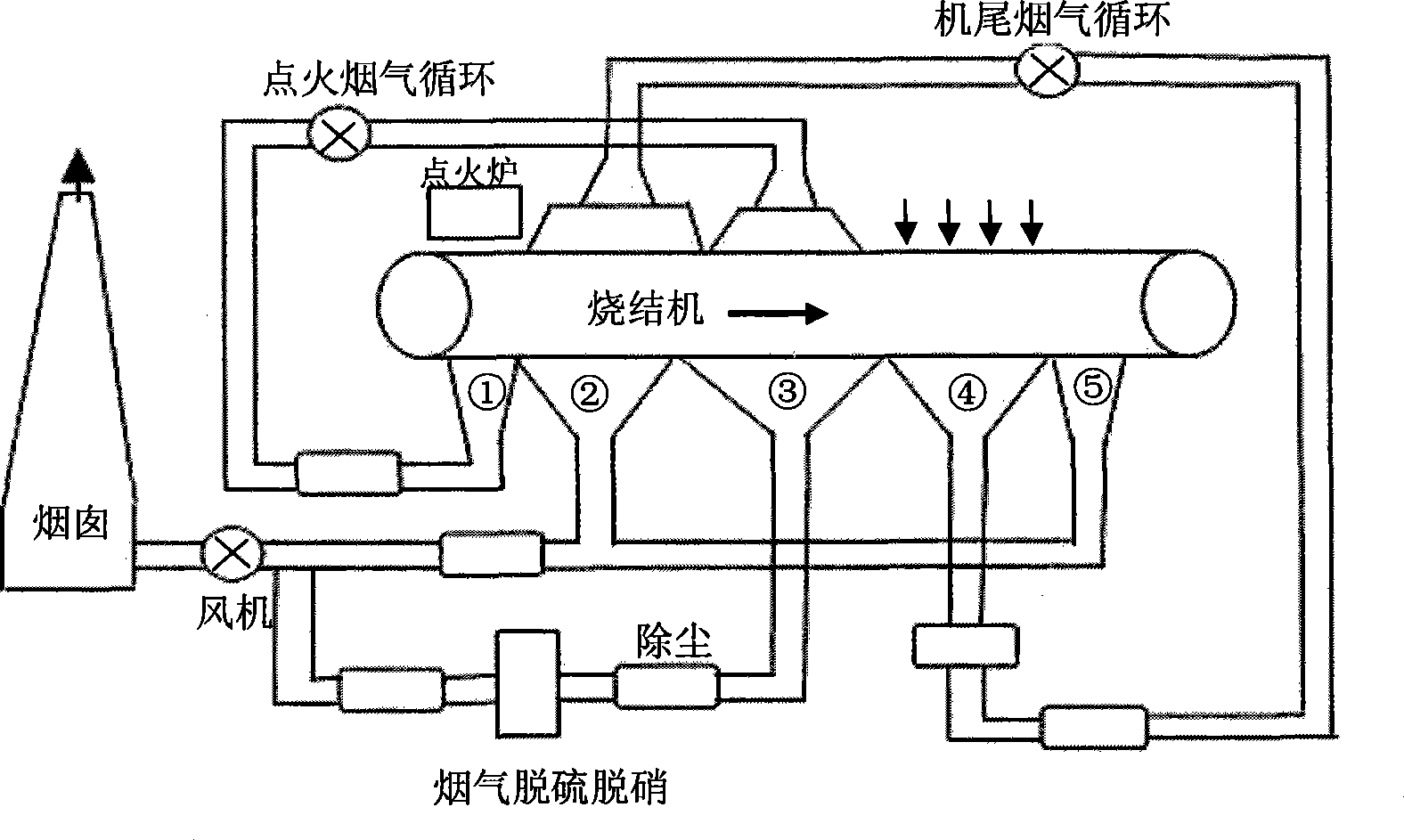

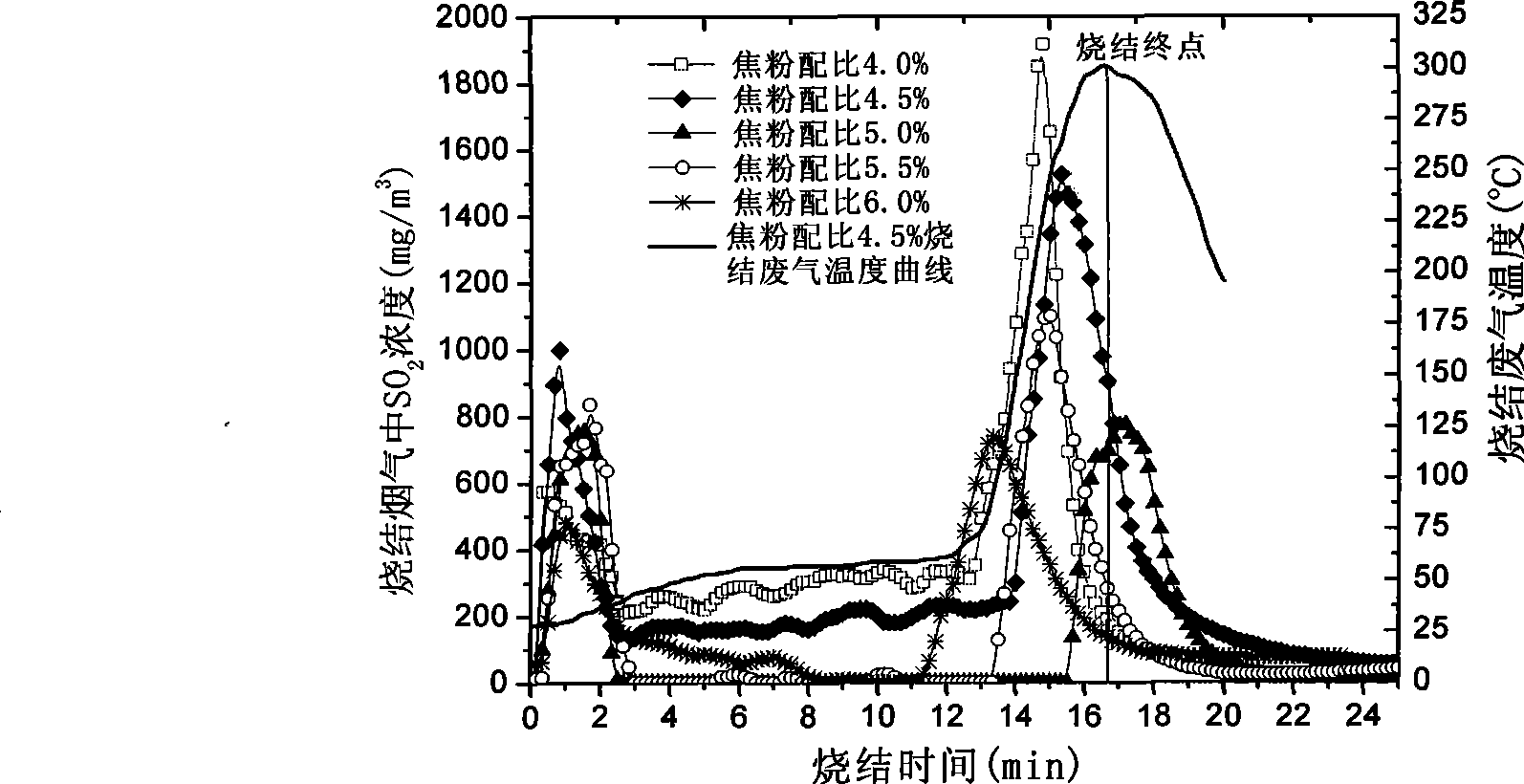

[0039] Sintering machine area 180m 2 , 15 sintered bellows, according to the traditional process, the limestone (lime)-gypsum method is used to desulfurize the flue gas of all the sintered bellows, and the sintered flue gas volume is 600kNm 3 / h, SO in flue gas 2 Average concentration 500mg / Nm 3 , sintering flue gas desulfurization efficiency 75%, flue gas denitrification efficiency 70%, SO in flue gas after desulfurization 2 Concentration 40mg / Nm 3 . This embodiment is divided into high SO 2 area, high SO 2 area outside the area. where high SO 2 The region outside the region is divided into the initial part of the ignition region, the ignition smoke region and the high SO 2 The area between the areas and the area at the end of the sintering machine.

[0040] According to the technical process of the present invention, the limestone (lime)-gypsum method is also adopted, and only the high-concentration SO2 is selectively processed without flue gas circulation. 2 Flue ...

Embodiment 2

[0043] Sintering machine area 180m 2 , 15 sintered bellows, according to the traditional process, the limestone (lime)-gypsum method is used to desulfurize the flue gas of all the sintered bellows, and the sintered flue gas volume is 600kNm 3 / h, SO in flue gas 2 Average concentration 600mg / Nm 3 , the desulfurization efficiency of sintering flue gas is 80%, and the SO in the flue gas after desulfurization 2 Concentration 38mg / Nm 3 . This embodiment is divided into high SO 2 area, high SO 2 area outside the area. where high SO 2 The region outside the region is divided into the initial part of the ignition region, the ignition smoke region and the high SO 2 Zones between zones, high SO 2 The area between the area and the tail of the sintering machine and the area of the tail of the sintering machine.

[0044] Press technological process of the present invention, adopt limestone (lime)-gypsum method equally, carry out high SO 2 Flue gas circulation in the zone betwe...

Embodiment 3

[0047] Sintering machine area 180m 2 , 15 sintered bellows, according to the traditional process, the limestone (lime)-gypsum method is used to desulfurize the flue gas of all the sintered bellows, and the sintered flue gas volume is 600kNm 3 / h, SO in flue gas 2 Average concentration 700mg / Nm 3 , the desulfurization efficiency of sintering flue gas is 82%, and the SO in the flue gas after desulfurization 2 Concentration 45mg / Nm 3 ; The present embodiment is divided into high SO 2 area, high SO 2 area outside the area. where high SO 2 The region outside the region is divided into the initial part of the ignition region, the ignition smoke region and the high SO 2 Zones between zones, high SO 2 The area between the area and the tail of the sintering machine and the area of the tail of the sintering machine.

[0048] According to the technical process of the present invention, limestone (lime)-gypsum method is also adopted to carry out ignition flue gas circulation an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com