Multi-clearance ceramet gas discharge tube with circumscribing triggering terminal

A technology of gas discharge tube and cermet, applied in the field of discharge tube, can solve the problems of MOV crushing, MOV breakdown and short circuit, high residual transmission voltage, etc., and achieve the effect of solving potential hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

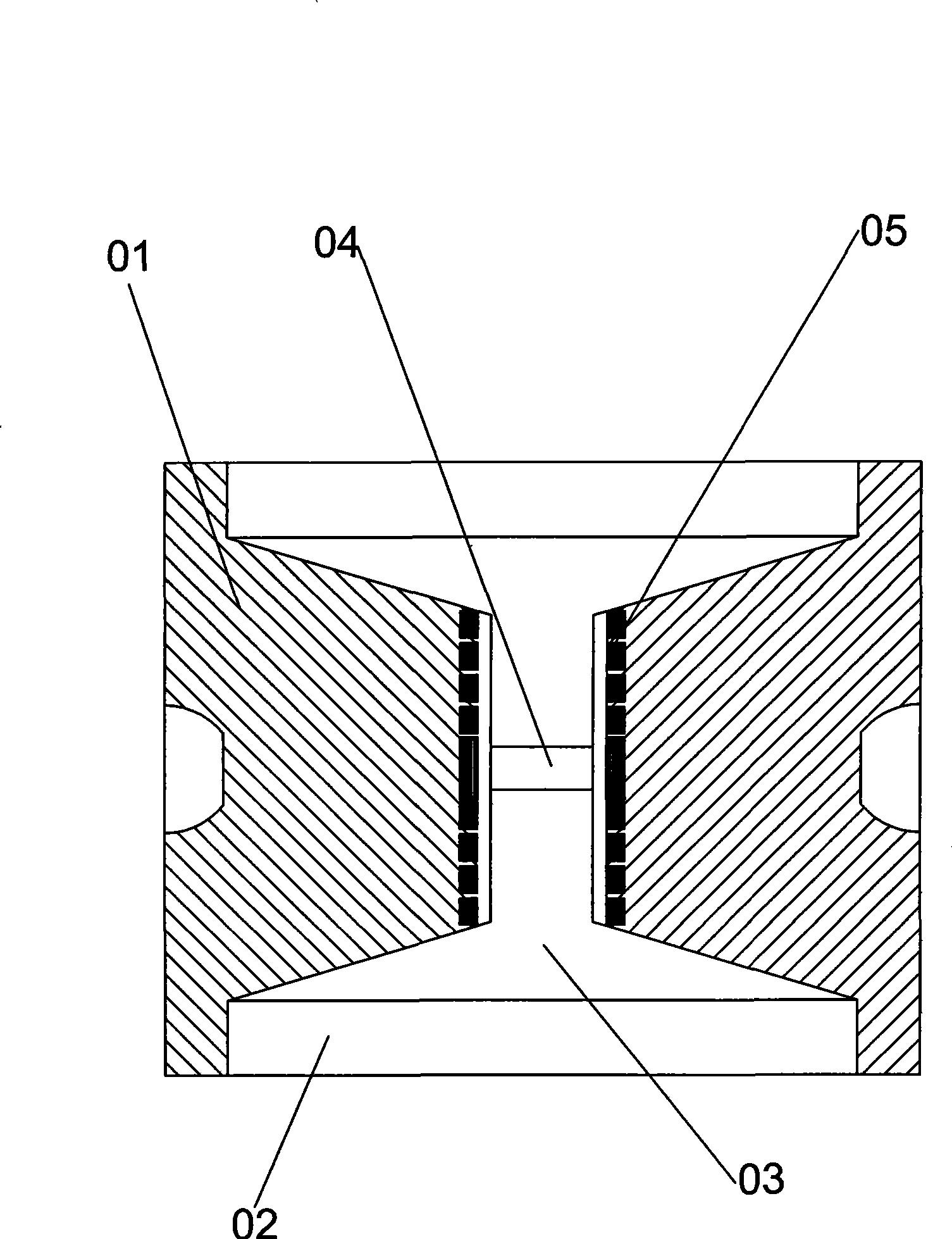

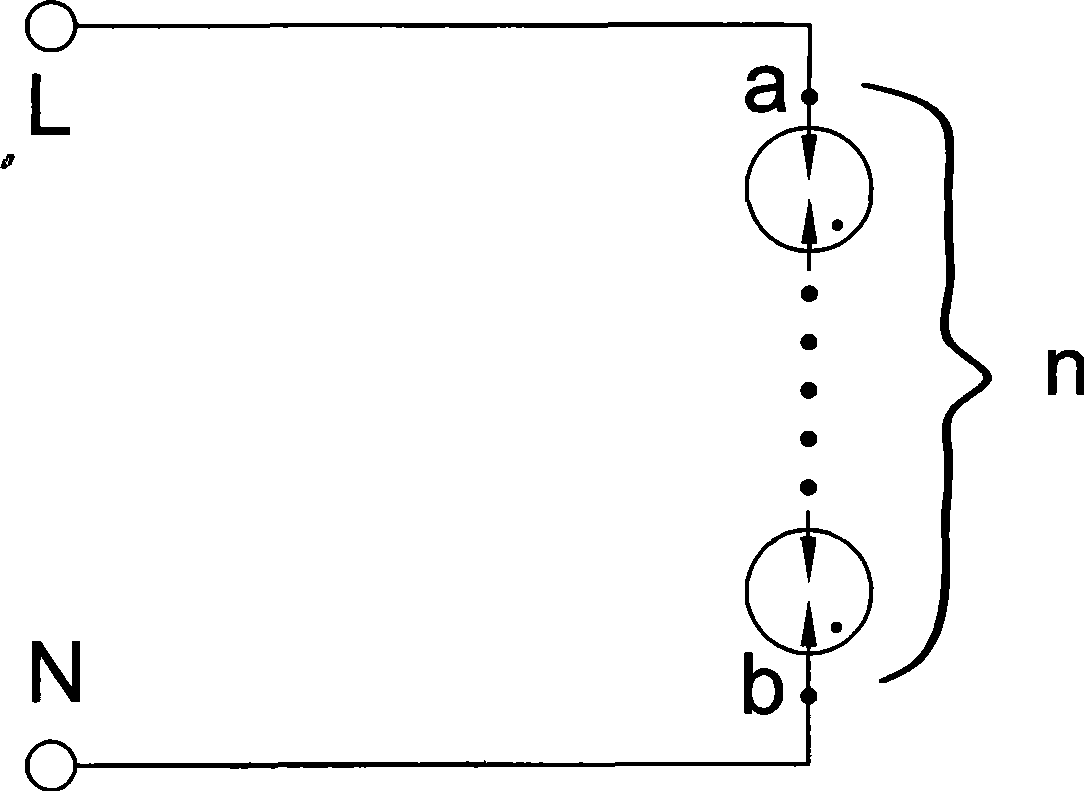

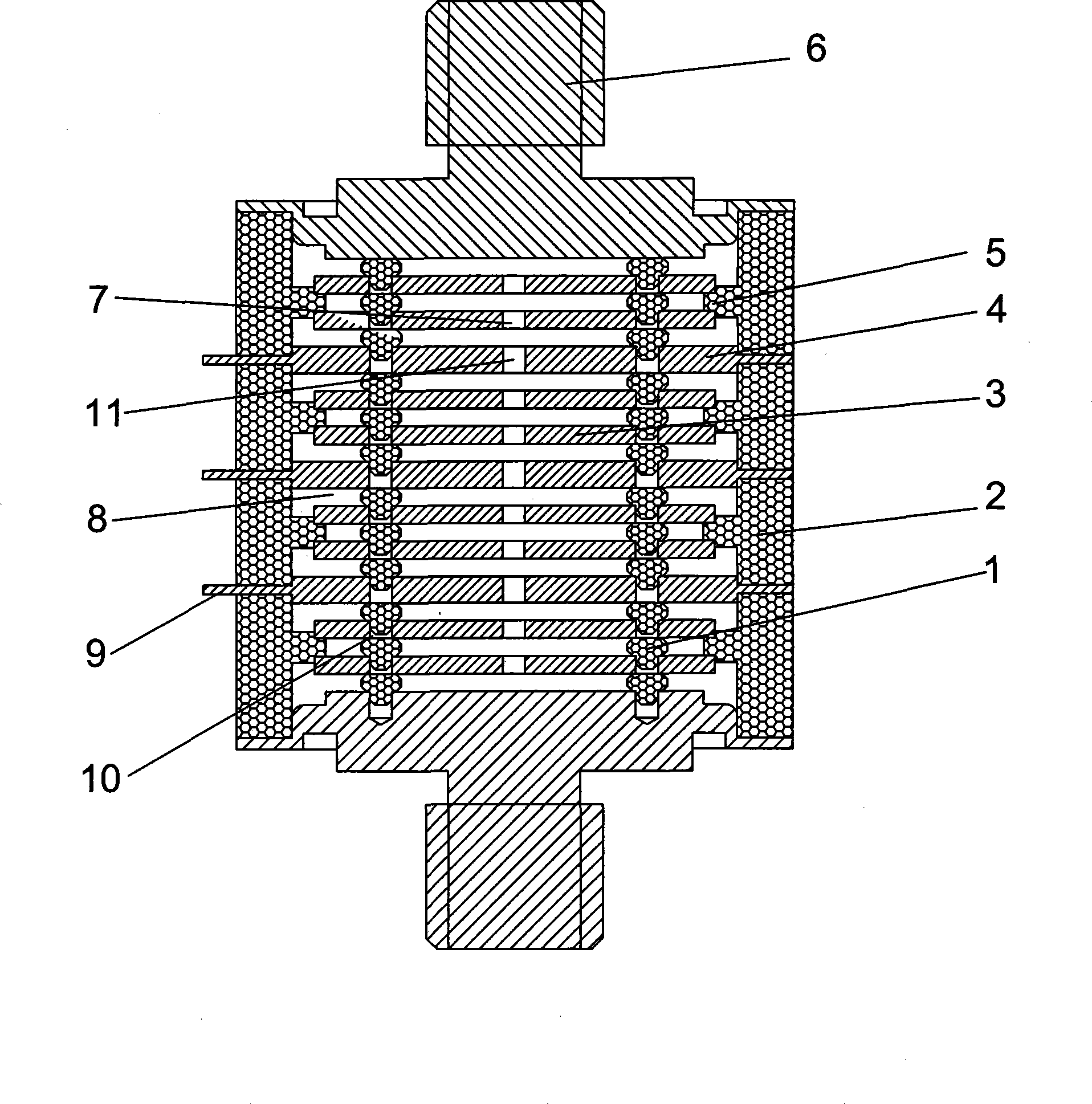

[0028] See figure 2 , 3 As shown, a multi-gap cermet gas discharge tube with an external contact trigger terminal includes ceramic positioning nails 1, metallized ceramic insulators 2, discharge gap electrode isolation plates 3, discharge gap transition connection isolation plates 4, screw electrodes 6, terminals 9. There are at least two layers of ring-shaped metallized ceramic insulators 2 connected with screw electrodes 6 to form a multi-gap space sealed with inert gas. The screw electrodes 6 can be made into different shapes according to needs. The ring-shaped metallized ceramic insulators 2 An annular flange 5 is integrally formed, and the upper and lower ends of the annular flange 5 support two electrode isolation plates 3 with discharge gaps. The electrode isolation plates 3 with discharge gaps are provided with ceramic positioning nail holes 10, discharge extension through holes 7, ceramic positioning nails A ceramic positioning nail 1 is installed in the hole 10, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com