Boiler water wall panel

A water-cooled wall and boiler technology, which is applied to boiler water pipes, steam boilers, steam boiler accessories, etc., can solve the problems of heavy welding work burden, corrosion-resistant alloy damage, welding defects, etc., to reduce the burden of welding work and work efficiency The effect of improving and stabilizing the working state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

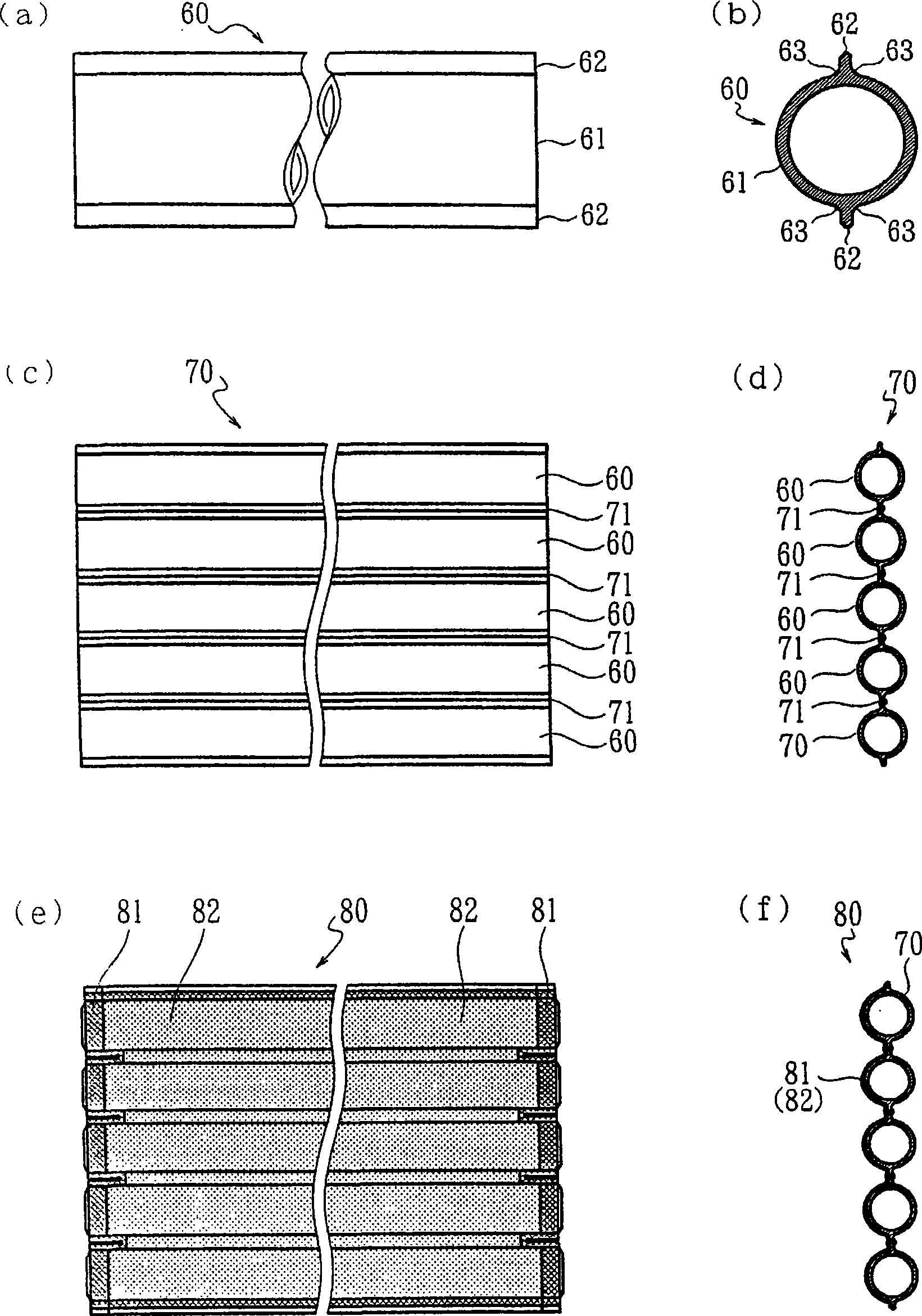

[0056] One embodiment of the structure and manufacturing method of the plate for boiler water walls of this invention is demonstrated with reference to drawings. figure 1 (a) is a side view of the finned tube body 60, (b) is its cross-sectional view; (c) is a side view of the plate base material 70, (d) is its cross-sectional view; (e) is a boiler It is a side view of the plate 80 for water walls, and (f) is a cross-sectional view thereof. Also, the cross sections in the respective cross-sectional views are cross sections perpendicular to the axial direction of the pipe body portion 61 .

[0057] This boiler water wall plate 80 is manufactured as follows: First, a metal seamless finned single tube as the minimum structural unit, that is, a finned tube body 60 is integrally manufactured in advance by a hot extrusion method. figure 1 (a), (b)); Then, for a plurality of such band finned tube bodies 60, after making their lengths consistent, they are mutually welded and connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com